Direct Push Unlocking Locking Mechanism Applied to Intelligent Integrated Feeder Cabinet and Its Feeder Cabinet

A locking mechanism and feeder cabinet technology, applied in the electrical field, can solve the problems of hidden safety hazards for operators, laborious operations, troublesome operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

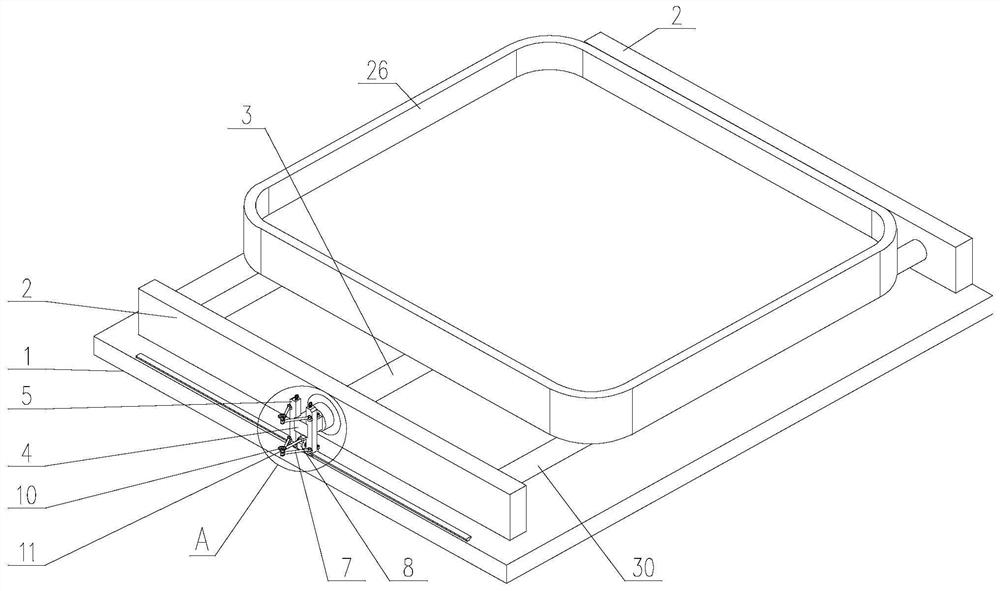

[0053] Such as Figure 1~Figure 11 As shown, the present invention is applied to the direct push unlocking locking mechanism of the intelligent integrated feeder cabinet. A screw 3 that is rotatably connected to a bearing seat 2, wherein,

[0054] One end of the screw rod 3 protrudes from the bearing seat 2 and is coaxially connected with the locking shaft body 4. The cross section of the locking shaft body 4 is non-circular, and a locking assembly is arranged at the end of the locking shaft body 4;

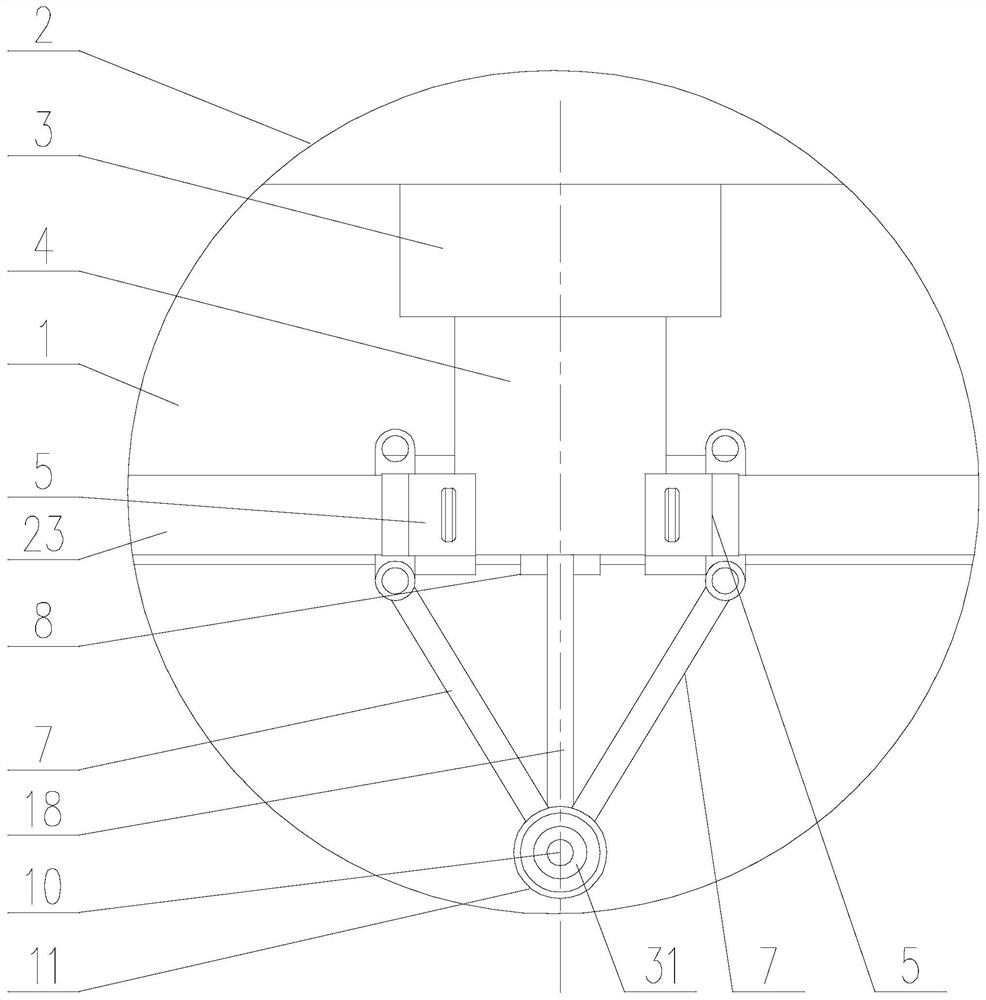

[0055] The locking assembly includes two clamping blocks 5 and a link mechanism and an elastic return mechanism that are both located between the clamping blocks 5 and are not opposite to the end face of the locking shaft body 4 . Both sides of the bottom are slidingly connected with the bottom plate 1, and the sliding direction is perpendicular to the axis of the screw rod 3, and on their opposite sides are provided with a slot 6 that can be fitted with the side wall of the loc...

Embodiment 2

[0063] This embodiment is a further optimization description of the structure in embodiment 1.

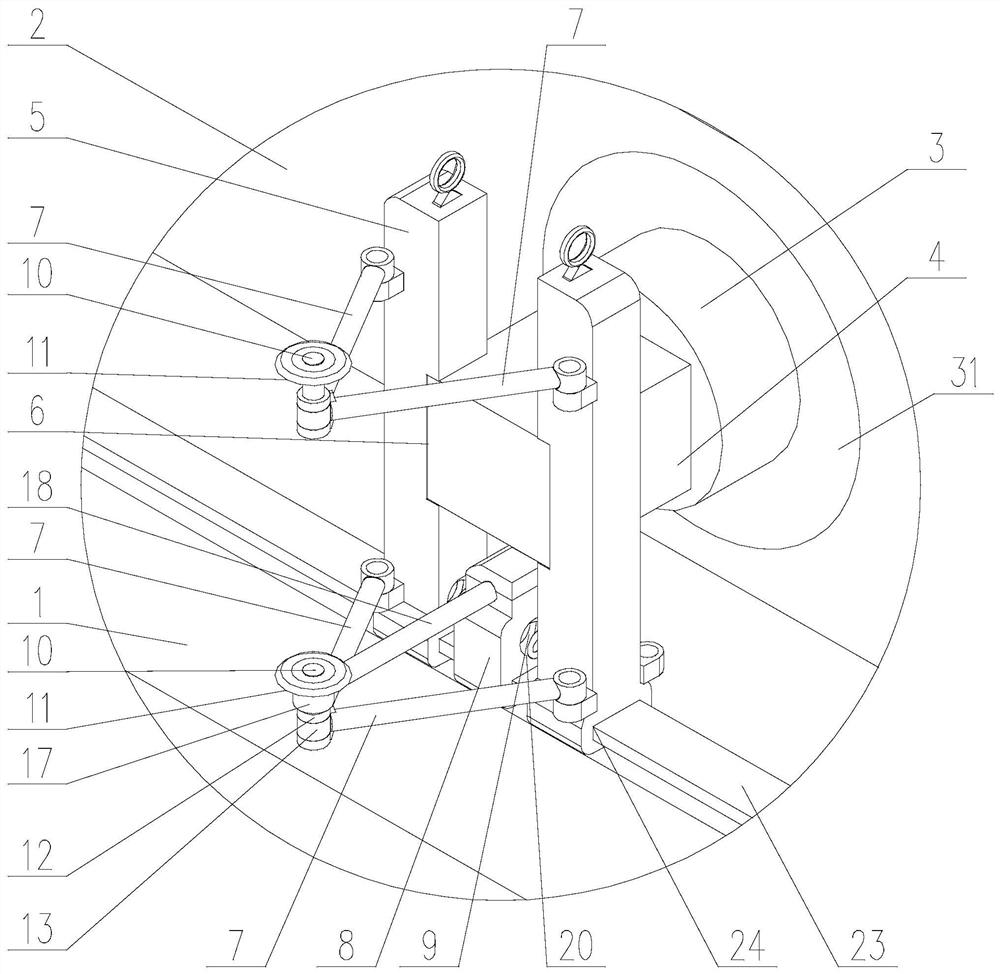

[0064] Such as figure 2 As shown, in the present invention, the linkage mechanism also includes a contact roller 11, and the hinge shaft at one end of the connecting rod 7 is an intermediate hinge shaft 10, and the top end of the intermediate hinge shaft 10 is rotatably connected with a Contact roller 11.

[0065] When the direct push unlocking locking mechanism is applied to the circuit breaker of the feeder cabinet, the circuit breaker is placed above the screw rod, and is driven by the screw rod to move forward and backward along the axis of the screw rod. One end force comes from closing the circuit breaker cabinet door, and the cabinet door rotates around the hinge on one side of its own axis, so the contact part on the cabinet door and the hinged end of the connecting rod 7 will gradually move away and close as the cabinet door closes. One side of the page is offset, that ...

Embodiment 3

[0067] About the structure of one end that connecting rod 7 is hinged mutually is as follows:

[0068] Such as figure 1 , Figure 4 as well as Figure 5 As shown, in the present invention, a first hinged cylinder 12 and a second hinged cylinder 13 are respectively connected to one end of the connecting rod 7 hinged to each other, and an axial dimension and a second hinged cylinder 13 are arranged in the middle of the first hinged cylinder 12 . Two articulated barrels 13 are sockets with matched axial dimensions, the second articulated barrel 13 is inserted into the socket, and the bottom end of the intermediate hinge shaft 10 passes through the upper side of the inner hole of the first articulated barrel 12 and the second articulated barrel in turn. After the 13 inner holes are threadedly connected with the lower side of the first hinge cylinder 12 inner holes;

[0069] An annular groove 14 is arranged on the hole wall of the lower inner hole of the inner hole of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com