Patents

Literature

60results about How to "Reduce kinetic friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Golf ball lubricant

InactiveUS6761645B1Reduce kinetic frictionImprove featuresGolf ballsSolid ballsEngineeringGround propulsion

A coating composition for a golf ball is comprised of a slippery, transparent or white, non-sticky lubricant film, and a method for applying same to a golf ball comprises the steps of applying the lubricant to an external surface of the golf ball prior to striking the ball with a golf club, and applying the coating uniformly to the external surface of the golf ball and to a sufficient degree as to reduce the friction between said external surface and the atmosphere or ground when propelled through the atmosphere or along the ground, respectively.

Owner:MEMORIAL LIGHTING

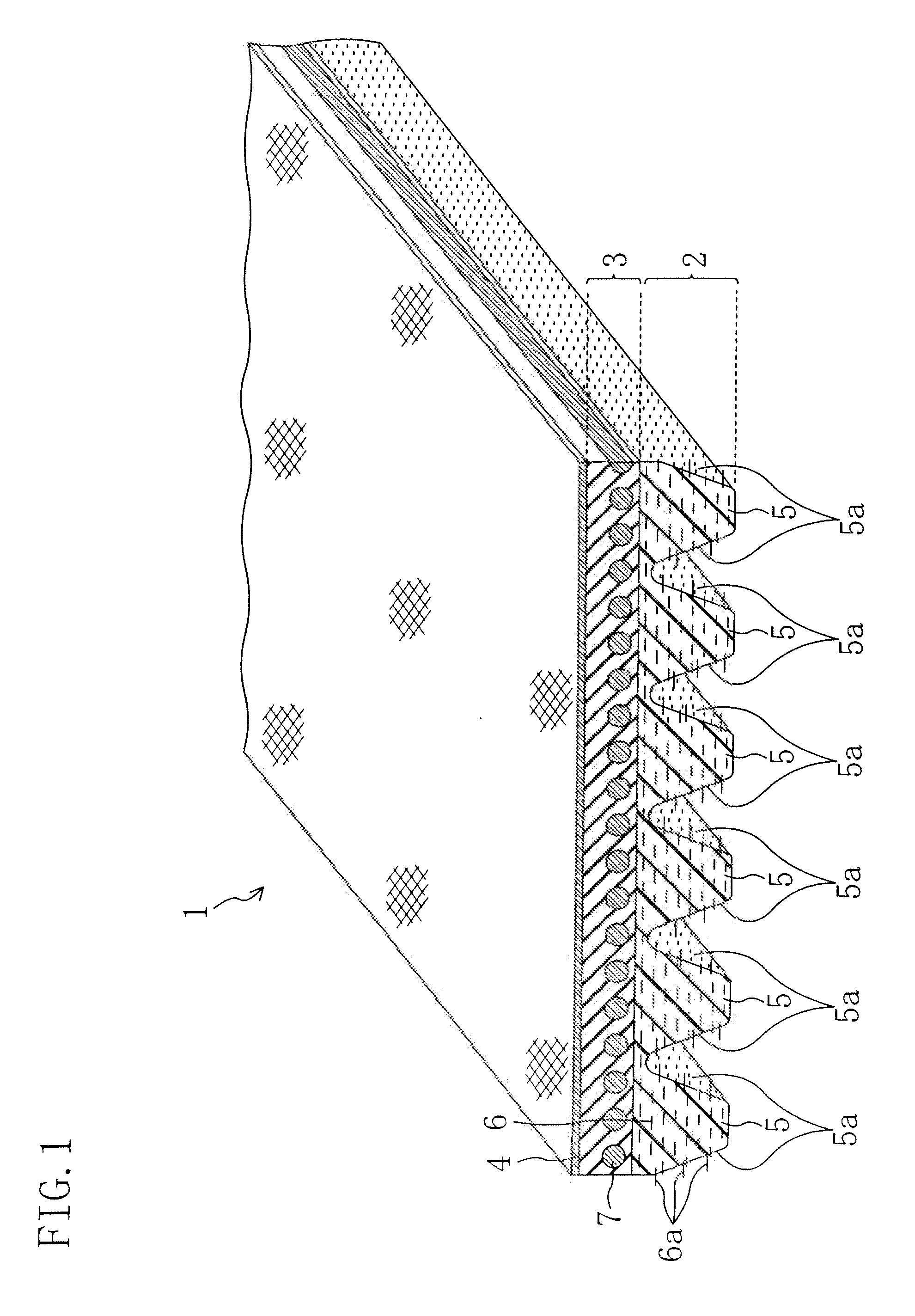

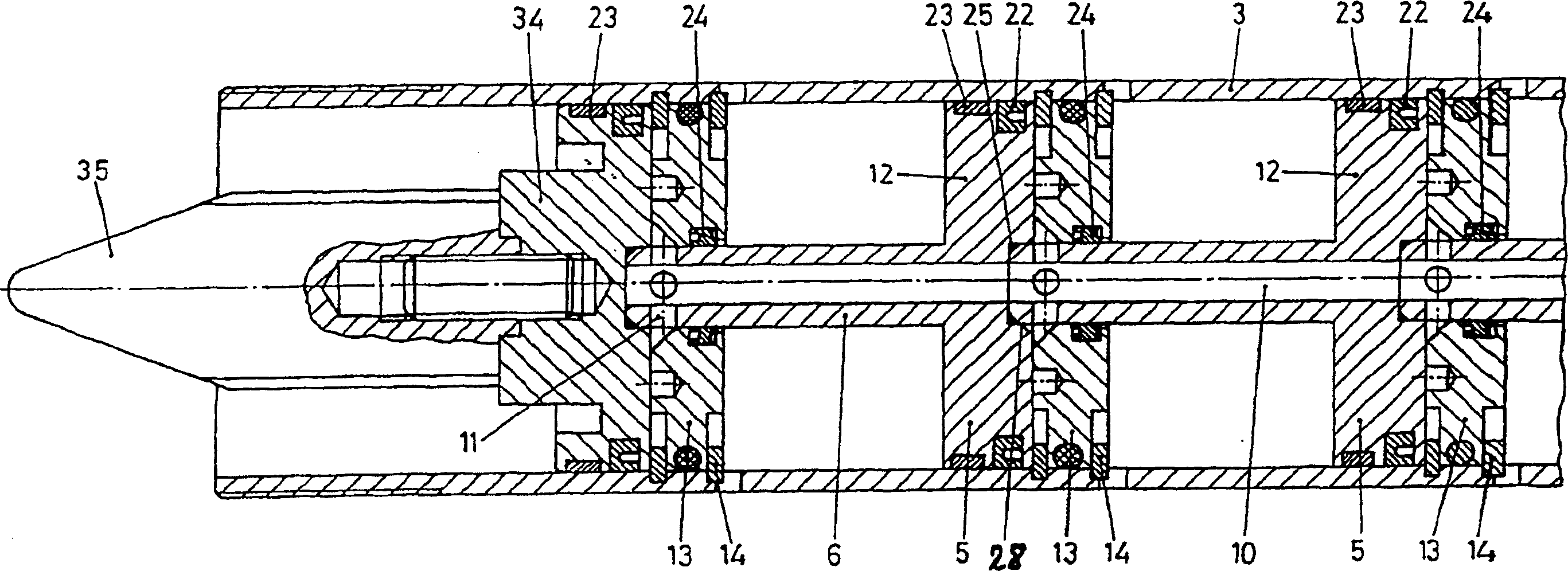

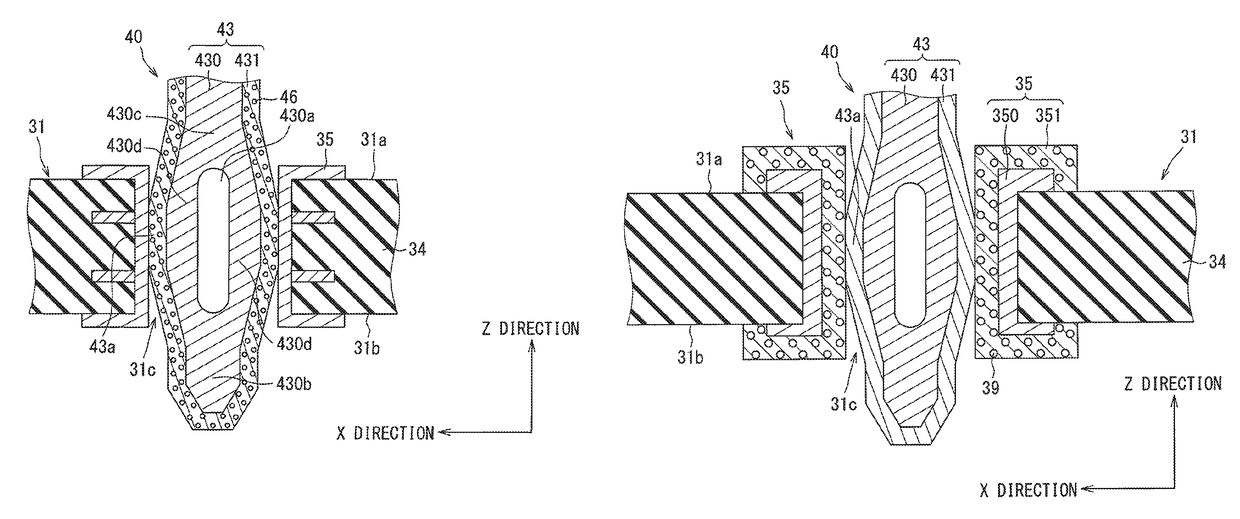

Floor covering

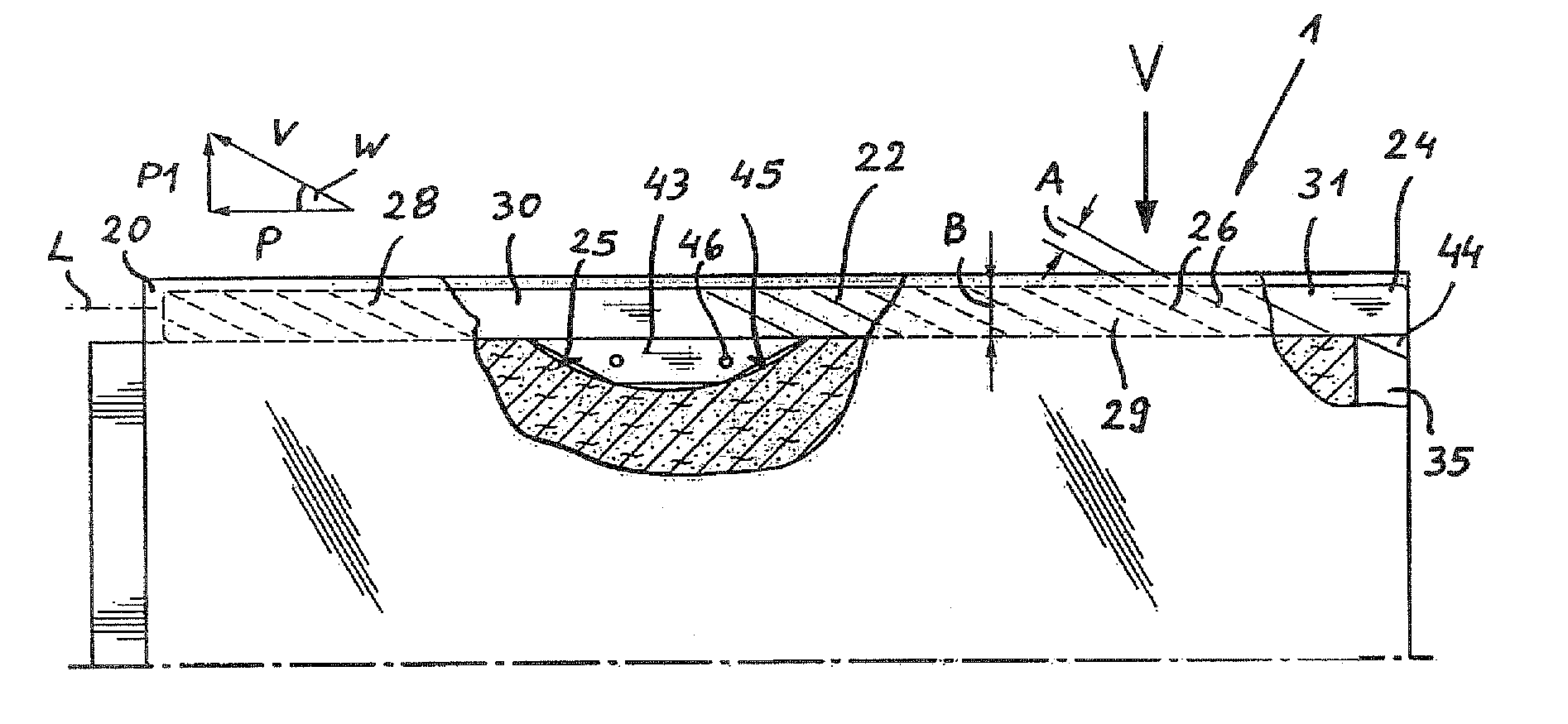

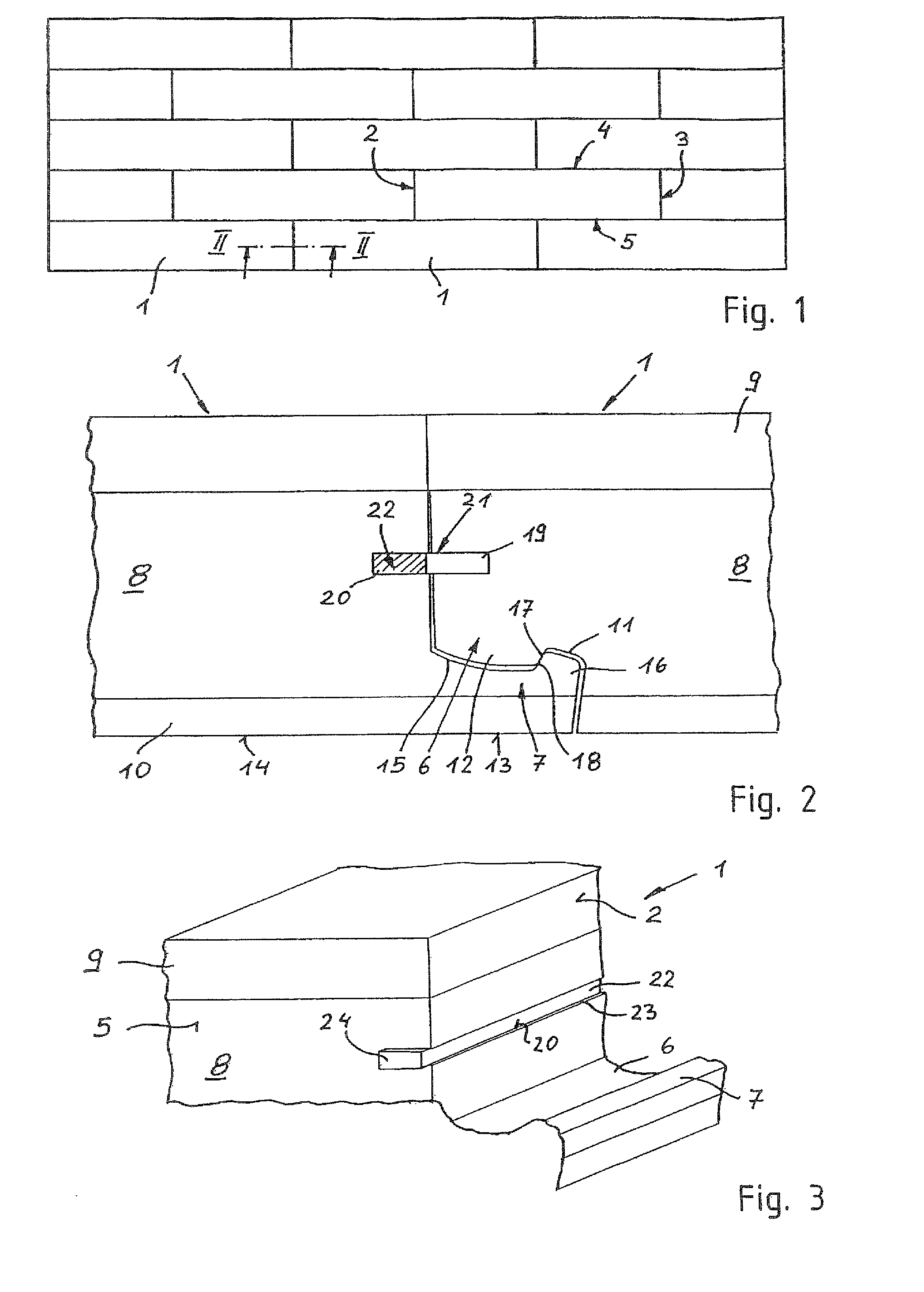

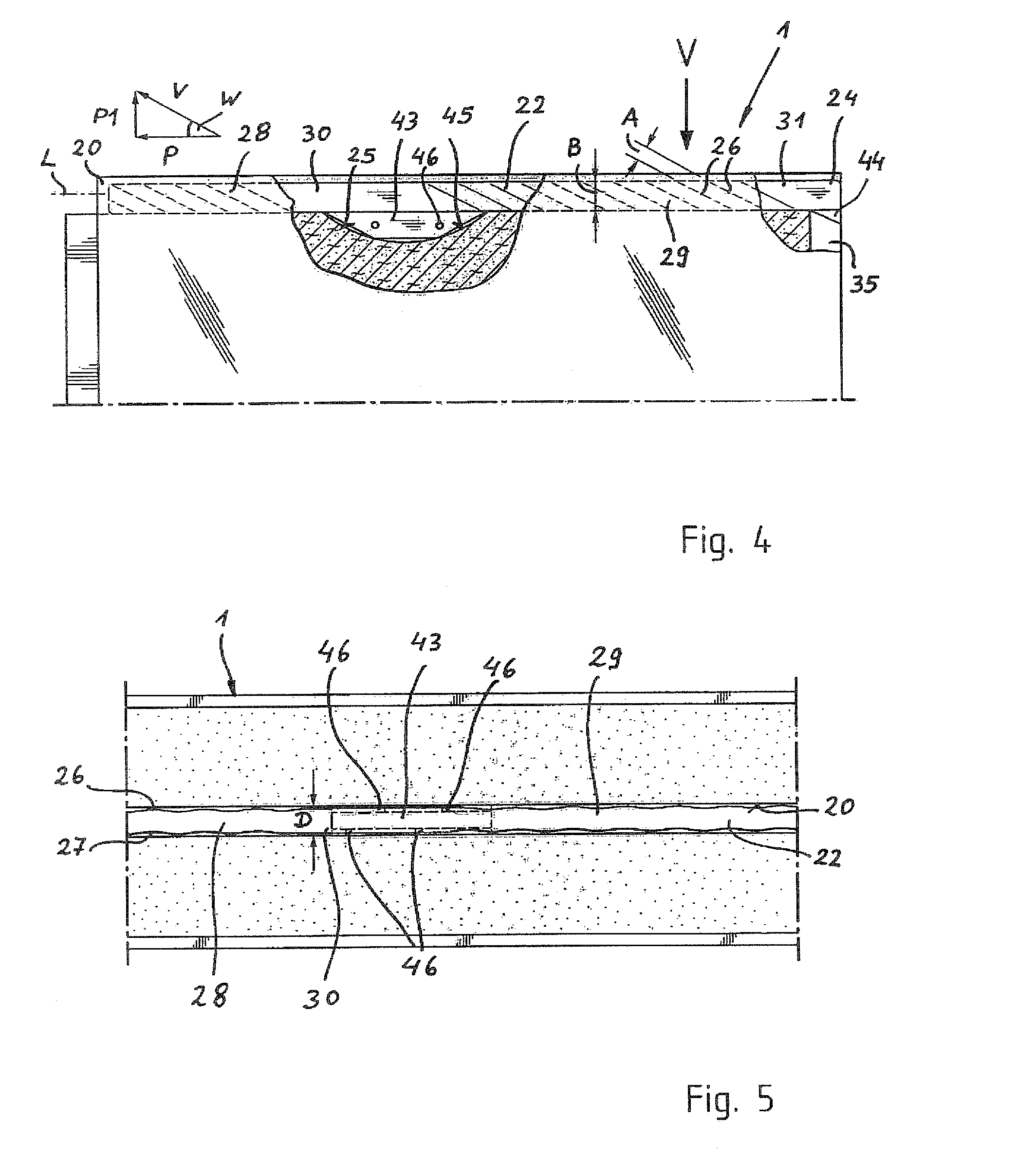

Disclosed is a floor covering consisting of a plurality of panel elements (1) that can be laid in combination with each other. On the front sides (2, 3) and longitudinal sides (4, 5), the panel elements (1) have locking strips (6, 7) that engage with each other in the assembled position in a covering in which panel elements (1) adjoin each other. The front sides (2, 3) of the panel elements (1) have grooves (19, 20). The grooves (19, 20) of two abutting front sides (2, 3) are aligned and form a locking channel (21) for accommodating a front spring (22) that is pre-assembled in one of the grooves (20). The front spring (22) projects from an end of the groove (20) that faces the longitudinal side (5) of the panel element (1) and can be moved in part from one groove (20) into the corresponding groove (19) of the adjoining panel element (1) by sliding the projecting end (24) of the front spring (22) into the groove (20). The groove (20) that accommodates the front spring (22) has at least one recess (45) within which a stop surface (25) is formed and into which a cam (43) of the front spring (22) engages. The front spring (22) has a wavy shape. The wavy sides of the front spring (22) face a decorative side and a bottom side of the panel elements (1). The orientation of the troughs (27) and crests (26) of the wavy zones (28, 29) should correspond to the direction of travel (V) of the front spring (22) when the front spring (22) is slid into the recess (45) and the cam (43) rests thereagainst.

Owner:SCHULTE GUIDO

Fluoropolyether-containing polymer-modified silane, surface treating agent, and article

ActiveUS20150274889A1High water/oil repellencyReduce kinetic frictionSilicon organic compoundsPolyether coatingsPolymer modifiedSilanes

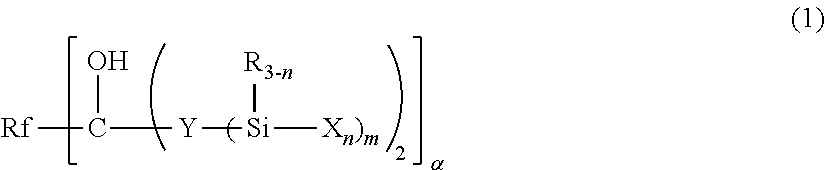

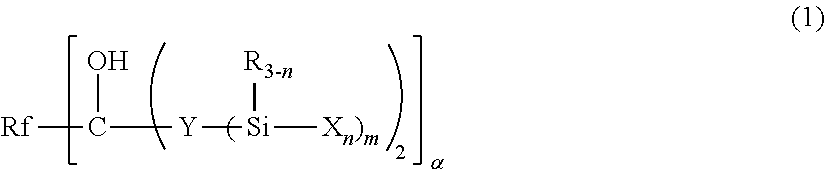

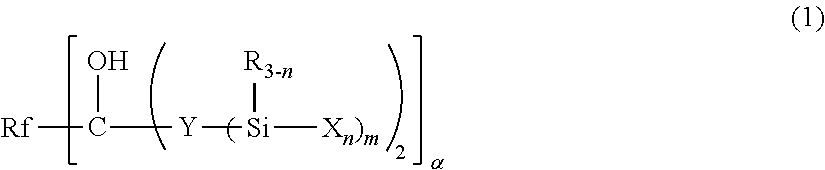

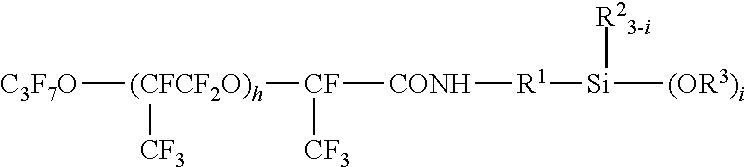

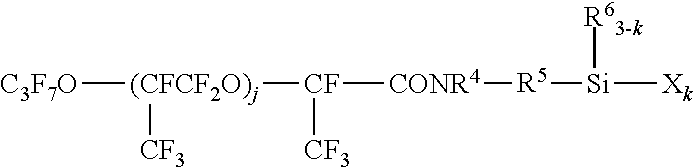

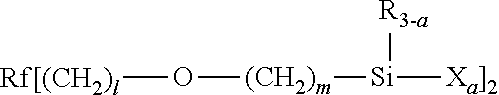

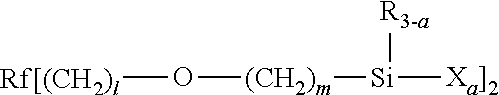

A fluoropolyether-containing polymer-modified silane having (1) is provided wherein Rf is a fluorooxyalkyl or fluorooxyalkylene-containing polymer residue, Y is a divalent to hexavalent hydrocarbon group, R is C1-C4 alkyl or phenyl, X is a hydrolyzable group, n is an integer of 1 to 3, m is an integer of 1 to 5, and α is 1 or 2. A surface treating agent comprising the silane or partial hydrolytic condensate thereof cures under mild conditions into a water / oil repellent layer having abrasion resistance, weatherability and low dynamic friction.

Owner:SHIN ETSU CHEM IND CO LTD

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

InactiveUS20120270057A1Reduction factorReduce kinetic frictionAnti-reflective coatingsPolyether coatingsPolymer sciencePolymer composition

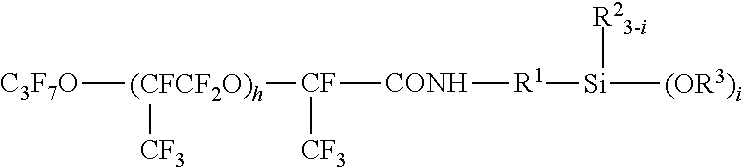

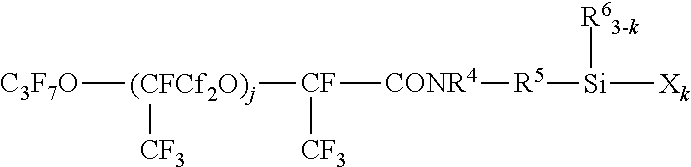

A fluorooxyalkylene group-containing polymer composition comprising a liner fluorooxyalkylene group-containing polymer represented by the formula (1) which has a hydrolysable group at a terminal and is hereinafter called “one-terminal hydrolyzable polymer”, and a liner fluorooxyalkylene group-containing polymer represented by the following formula (2) which has hydrolysable groups at the both terminals and is hereinafter called “both-terminal hydrolyzable polymer”, wherein an amount of the both-terminal hydrolyzable polymer is 0.1 mole % or more and less than 10 mole %, relative to total mole of the one-terminal hydrolyzable polymer and the both-terminal hydrolyzable polymer.

Owner:SHIN ETSU CHEM IND CO LTD

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

ActiveUS8900711B2Improve wear resistanceReduction factorOther chemical processesSynthetic resin layered productsPolymer sciencePolymer composition

A fluorooxyalkylene group-containing polymer composition including a liner fluorooxyalkylene group-containing polymer represented by the formula (1) which has a hydrolysable group at a terminal and is hereinafter called “one-terminal modified polymer”, and a liner fluorooxyalkylene group-containing polymer represented by the following formula (2) which has hydrolysable groups at the both terminals and is hereinafter called “both-terminal modified polymer”, wherein an amount of the both-terminal modified polymer is 0.1 mole % or more and less than 10 mole %, relative to a total mole of the one-terminal modified polymer and the both-terminal modified polymer.

Owner:SHIN ETSU CHEM IND CO LTD

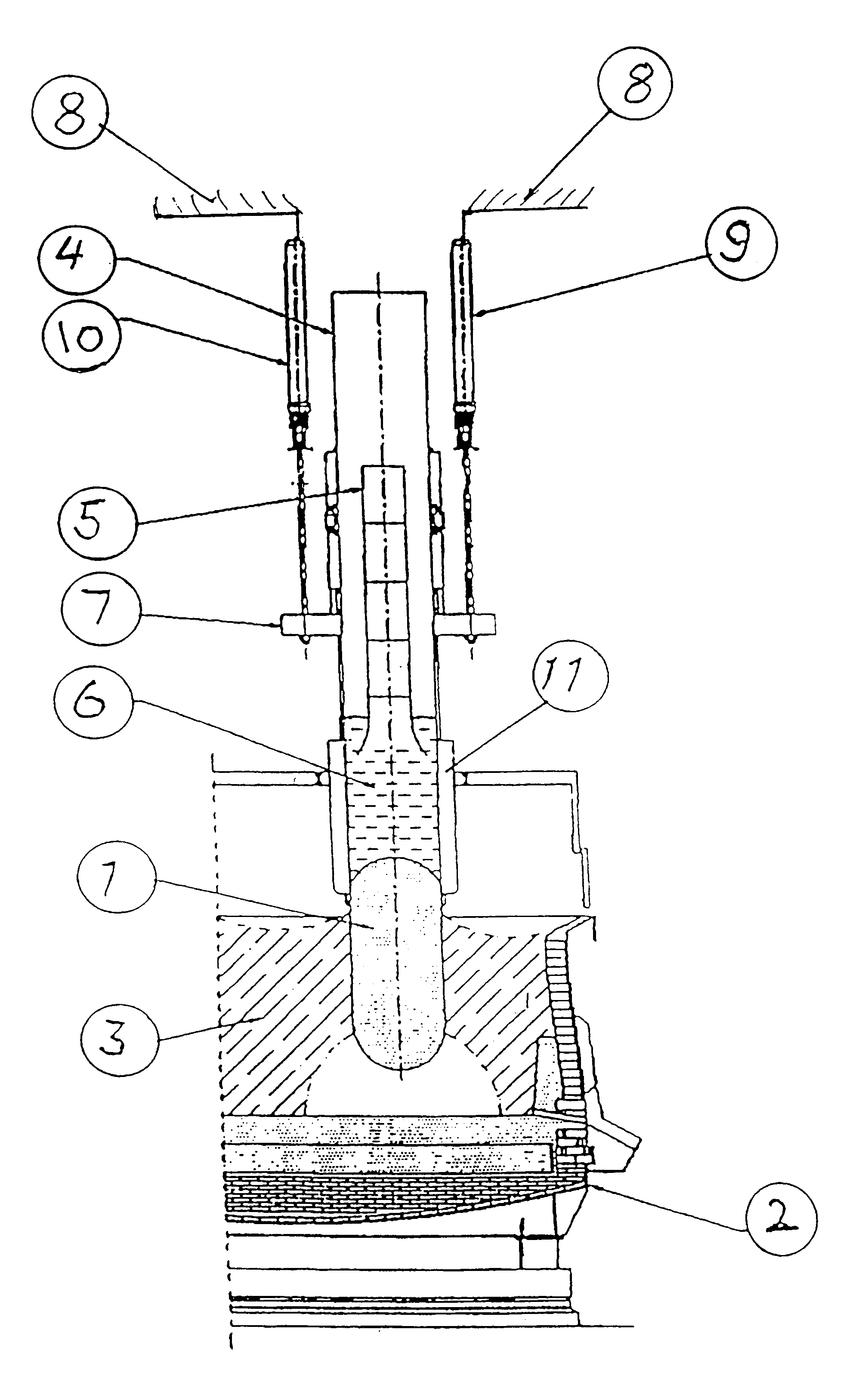

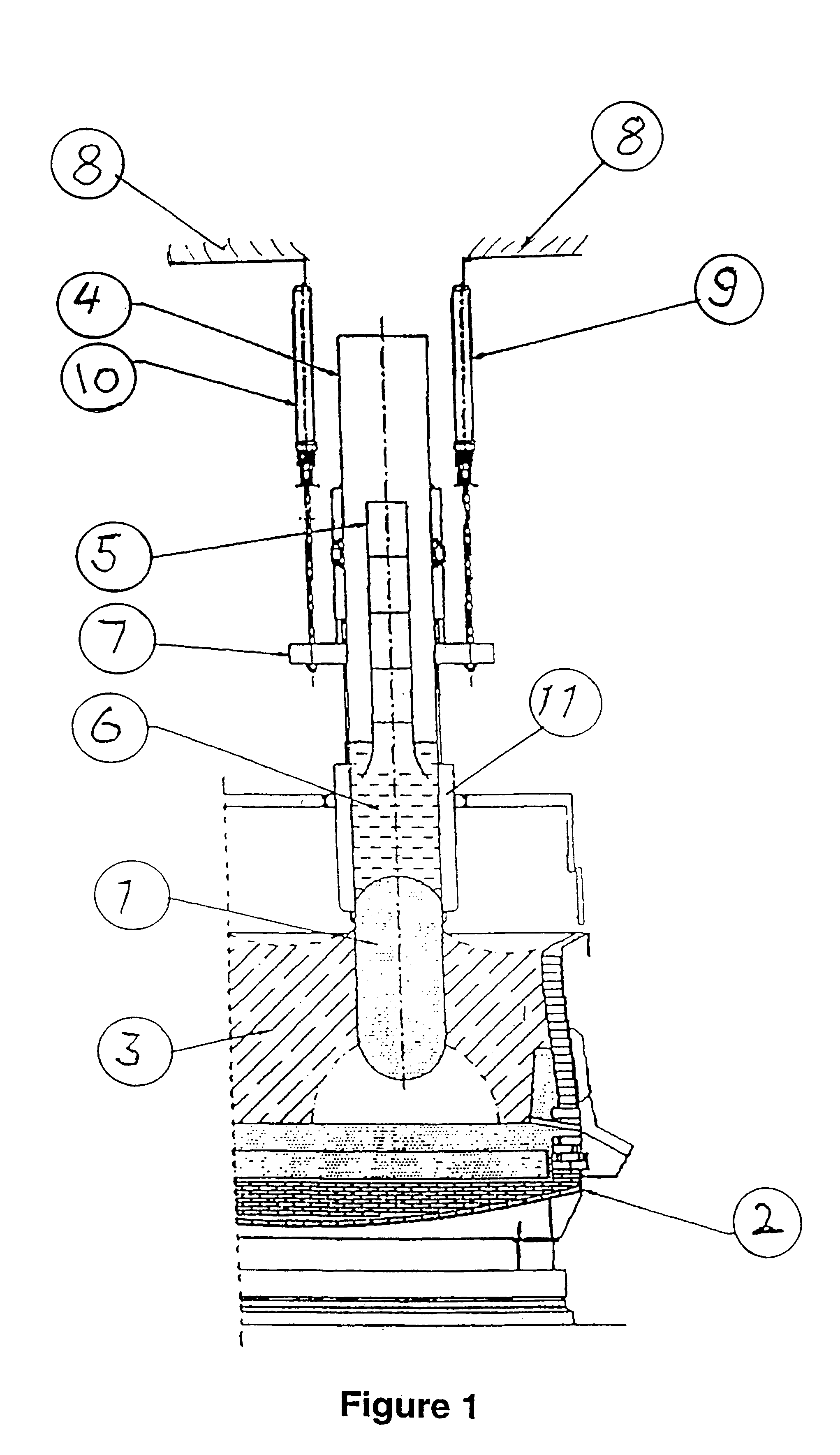

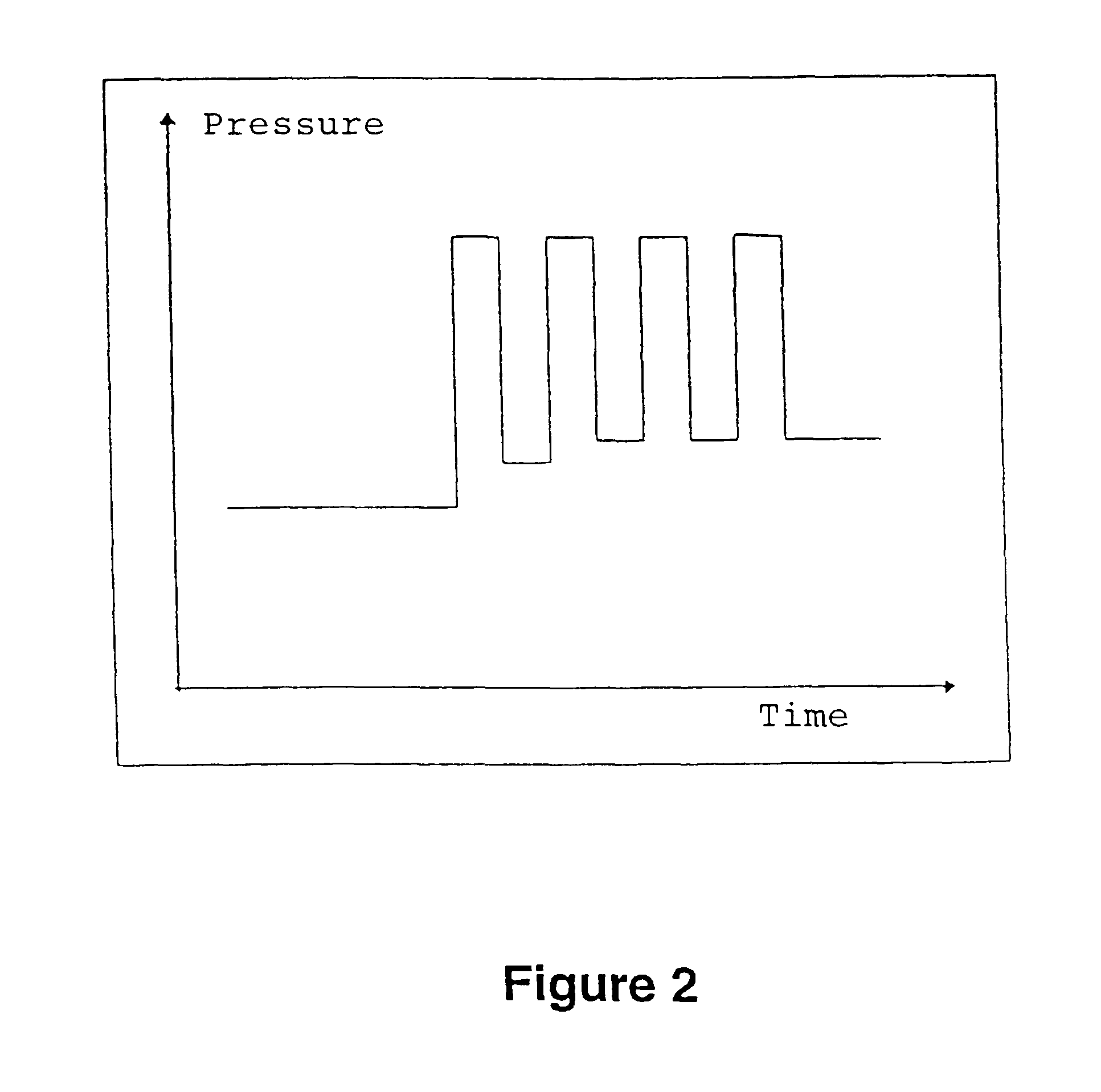

Method for weighing electrodes in electric smelting furnaces

InactiveUS6330270B1Eliminate frictionExclude influenceElectric discharge heatingSpecial purpose weighing apparatusOptoelectronicsElectrode

The present invention relates to a method for weighing an electrode submerged in the charge of an electric smelting furnace. The electrode is moved in vertical direction at least once, whereafter the electrode is lifted and the weight of the electrode is registered shortly after the electrode has been lifted.

Owner:ELKEM

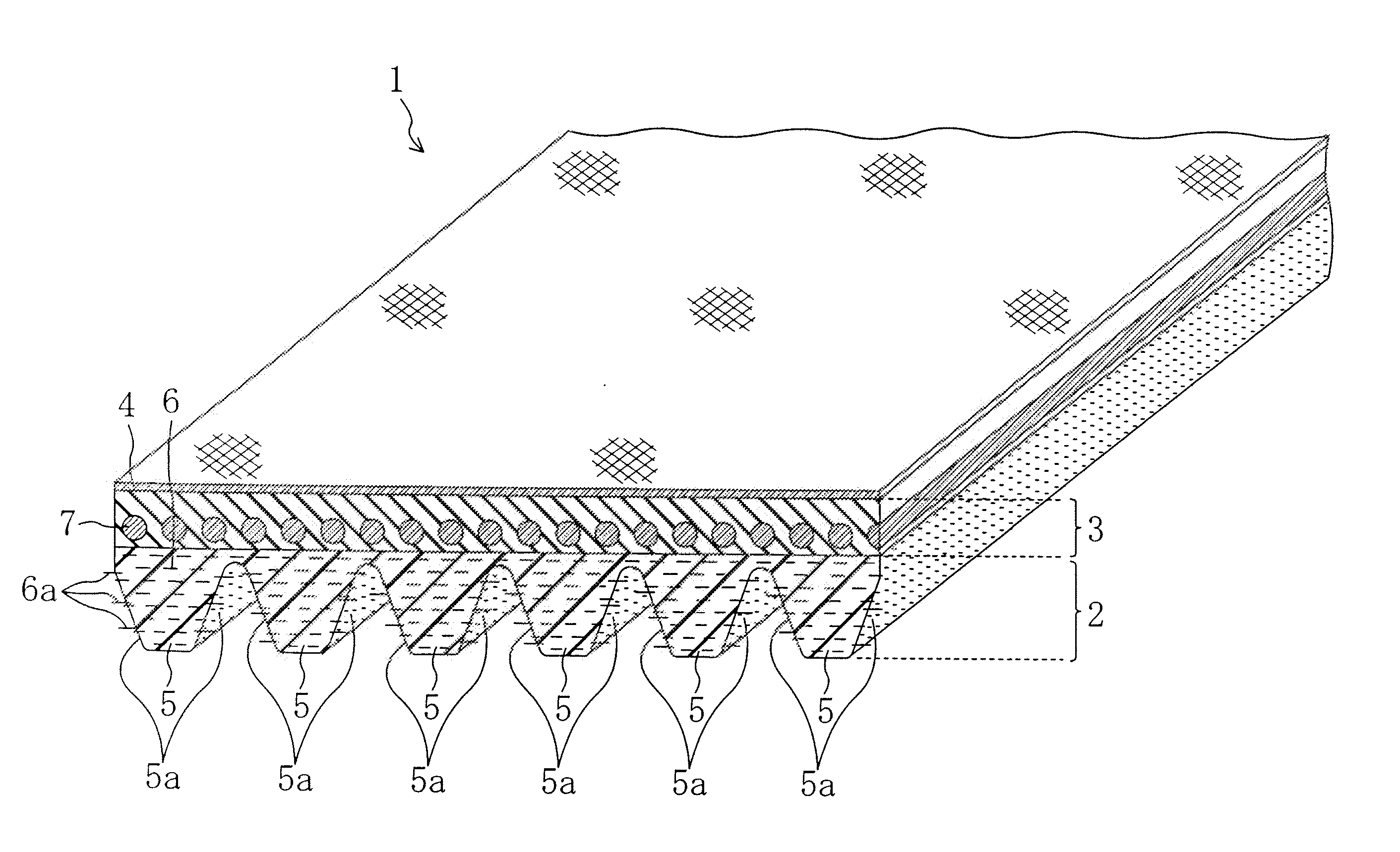

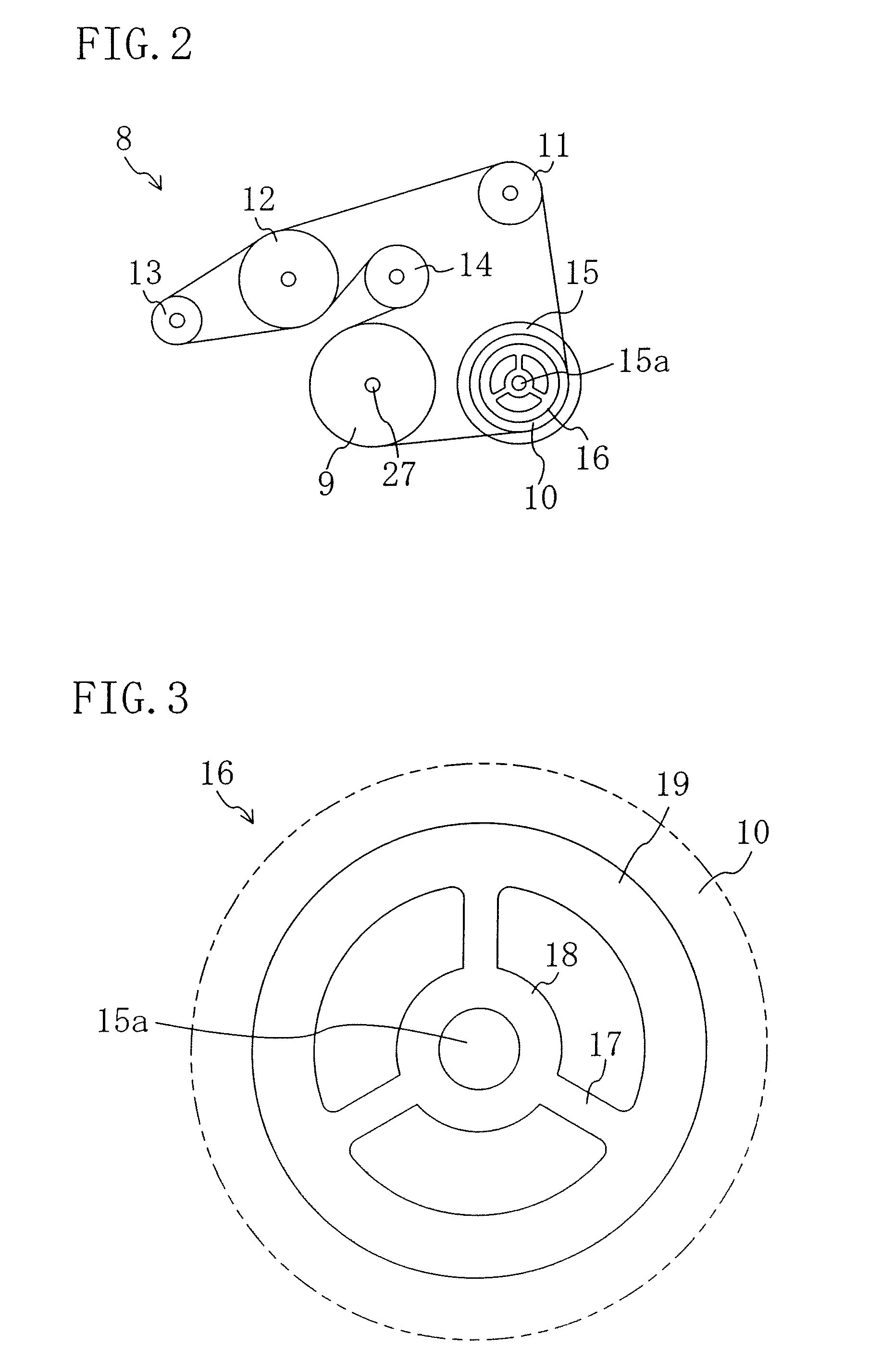

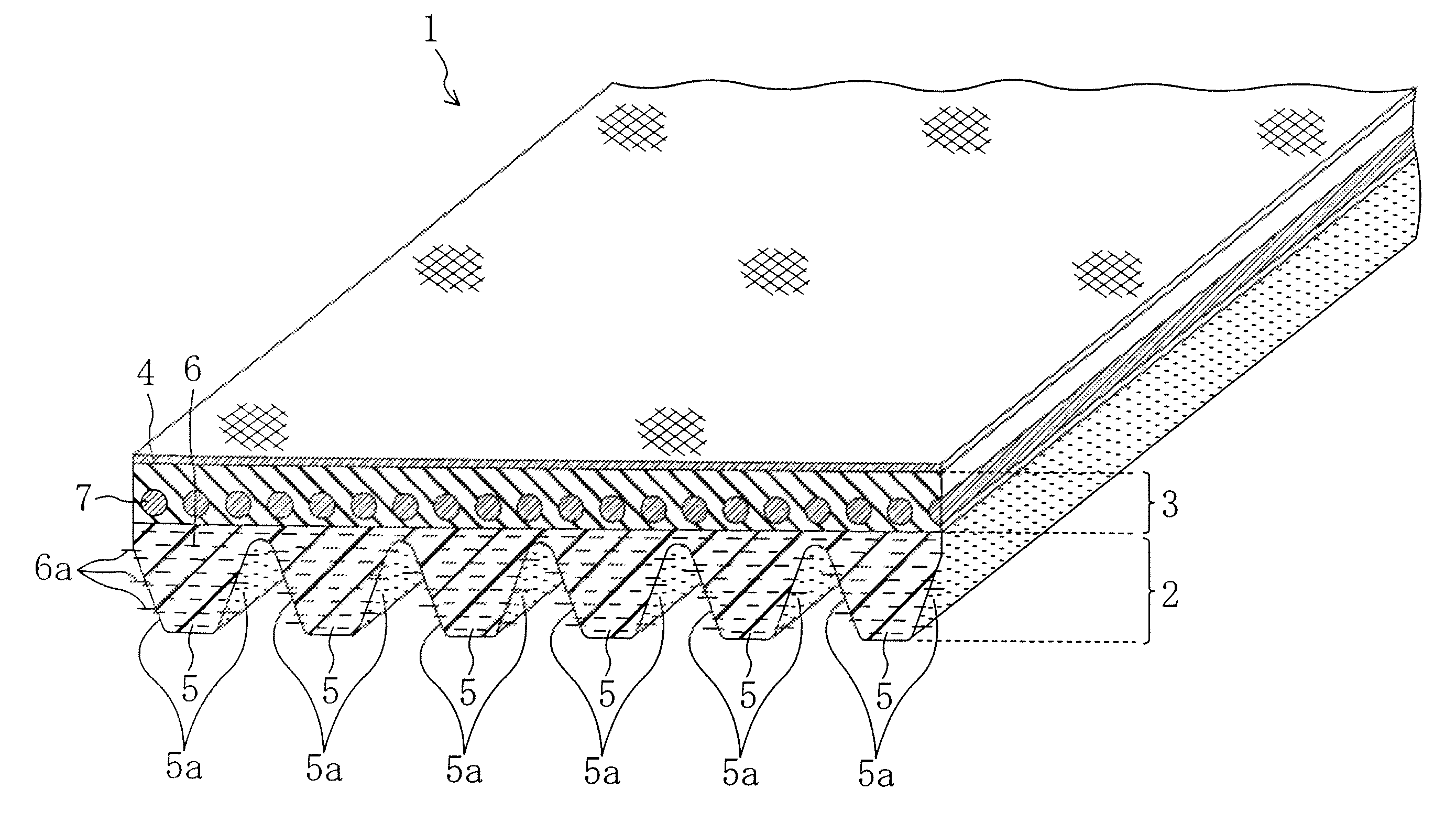

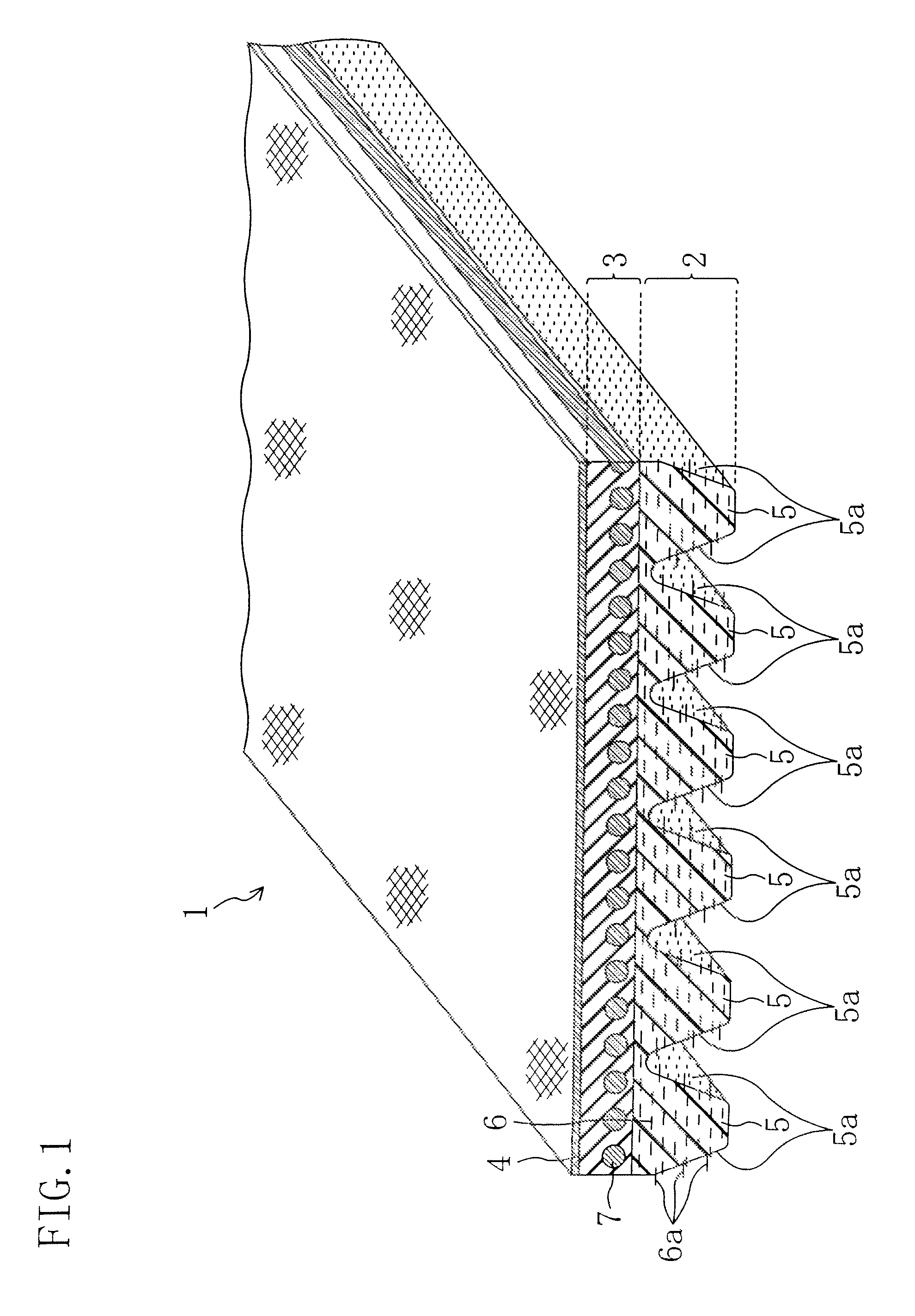

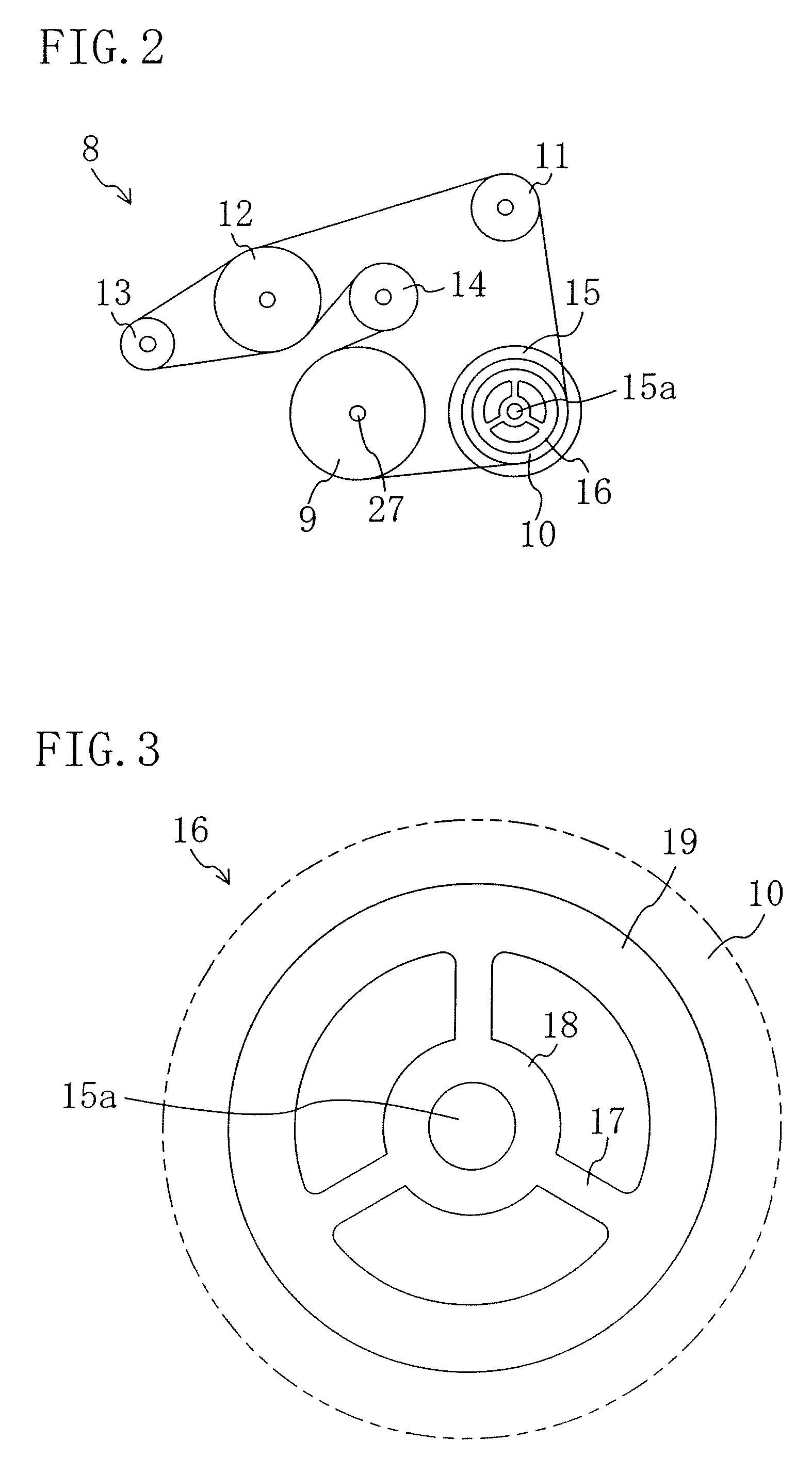

V-ribbed belt

InactiveUS20080026897A1Good lookingSuppresses noise generationV-beltsRopes and cables for vehicles/pulleyFiberEngineering

Short fibers 6a protruded from side faces 5a of rubber ribs 5 are thermal contracted by frictional heat by belt slip of the rubber rib side faces 5 on a V groove face of a pulley. This allows the short fibers 6a to be buried in rubber ribs 5.

Owner:BANDO CHEM IND LTD

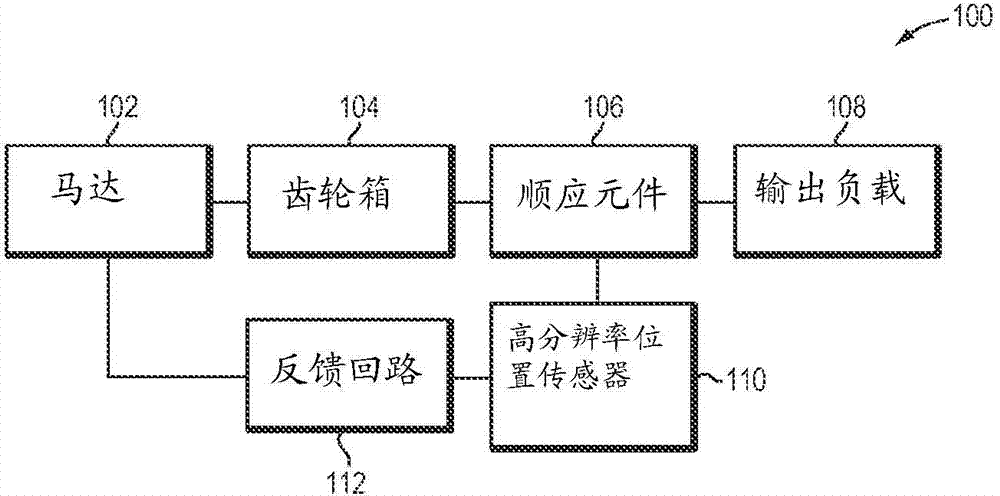

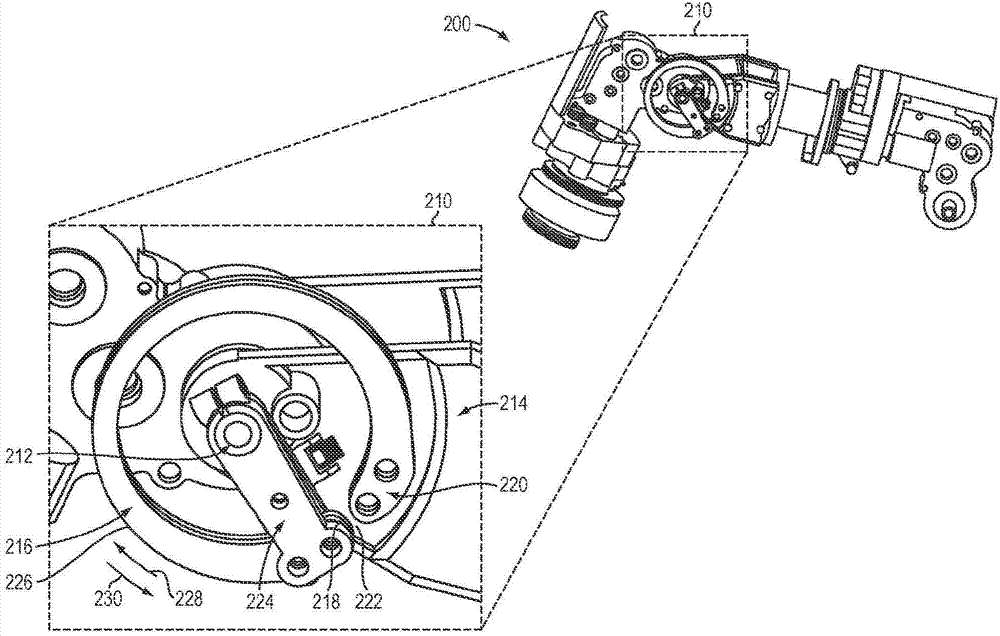

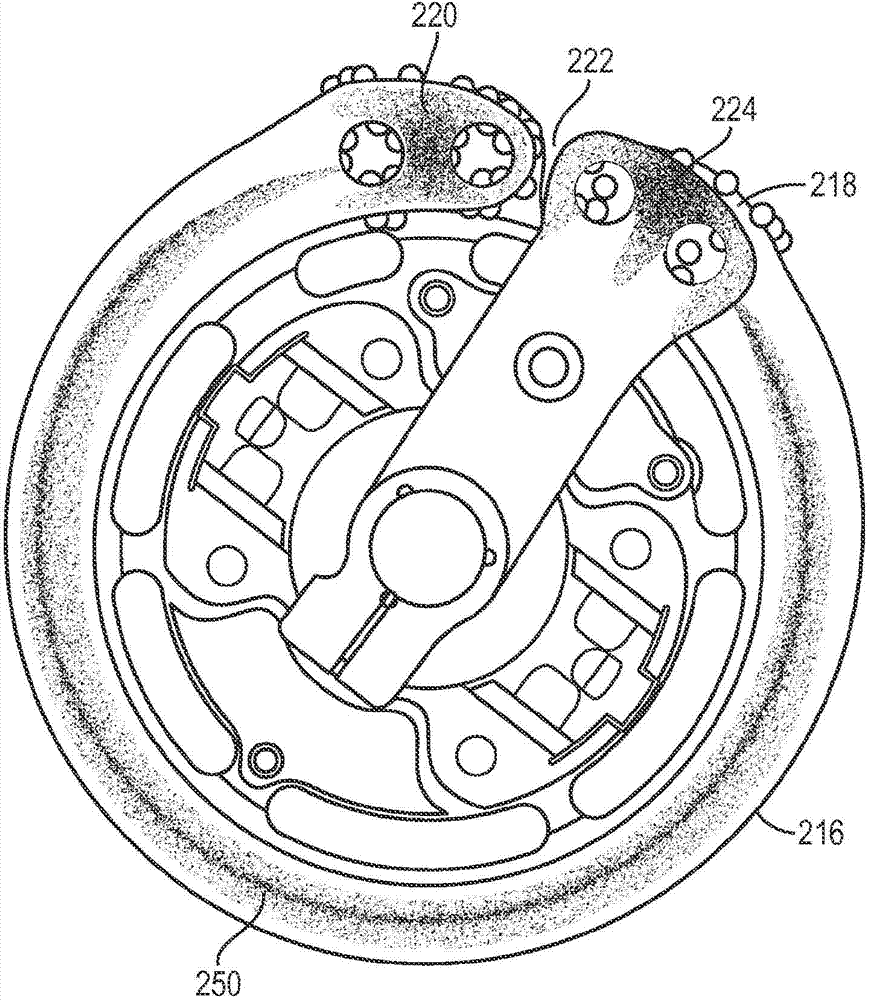

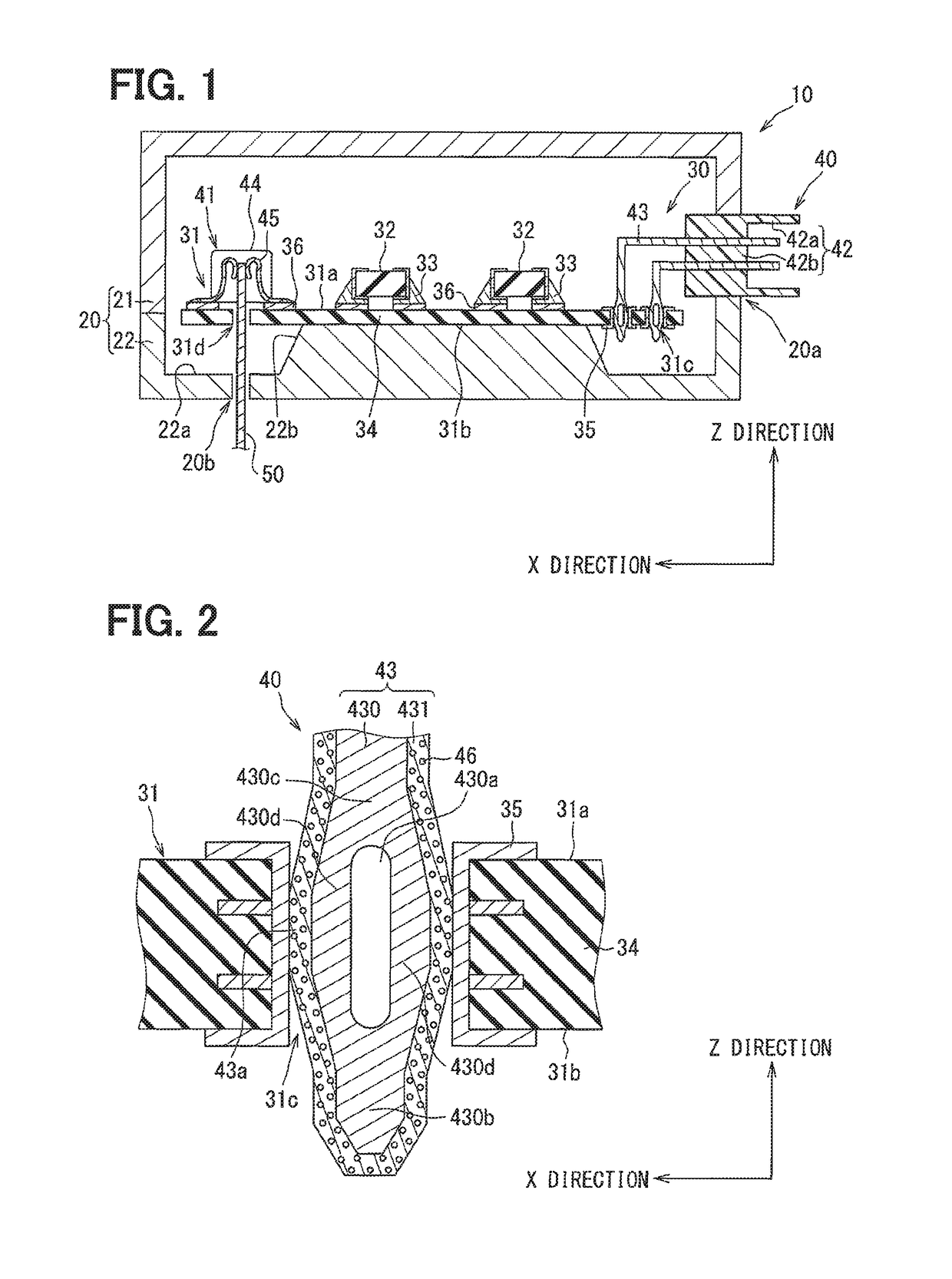

Flexure elements for series elastic actuators and related methods

ActiveCN104245247AUniform stressUniform deformationProgramme-controlled manipulatorJointsRobotic systemsActuator

Owner:RETHINK ROBOTICS +2

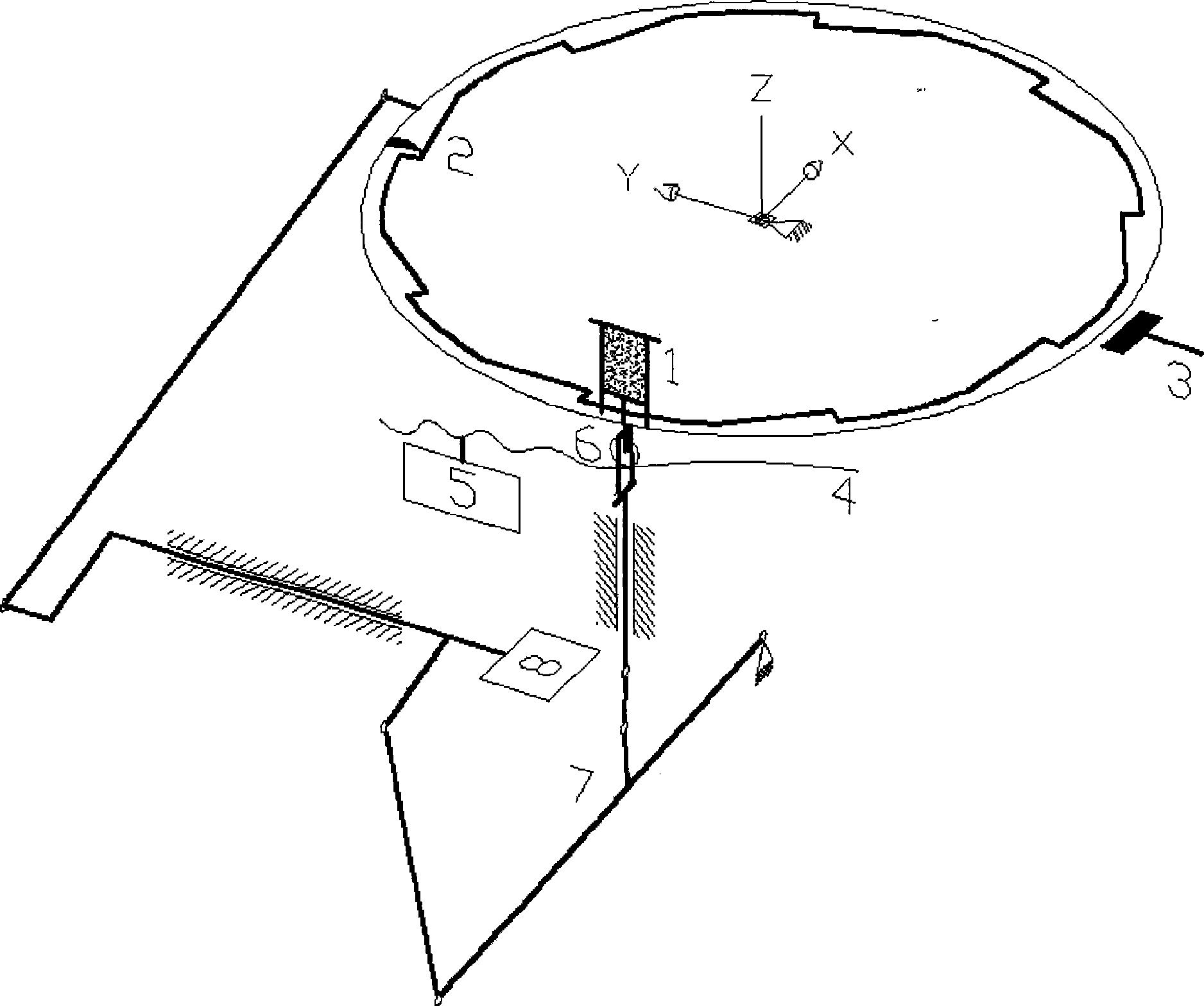

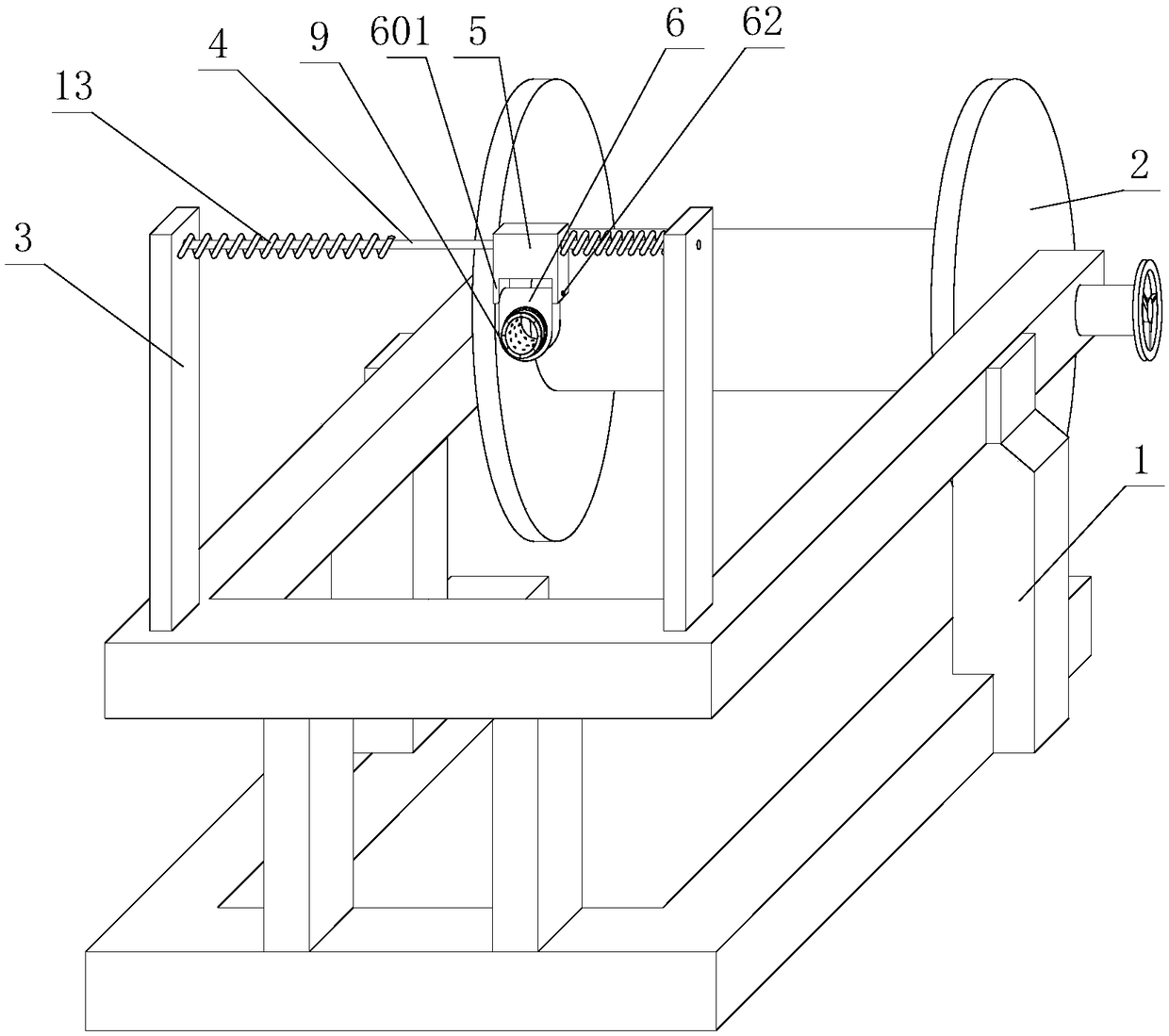

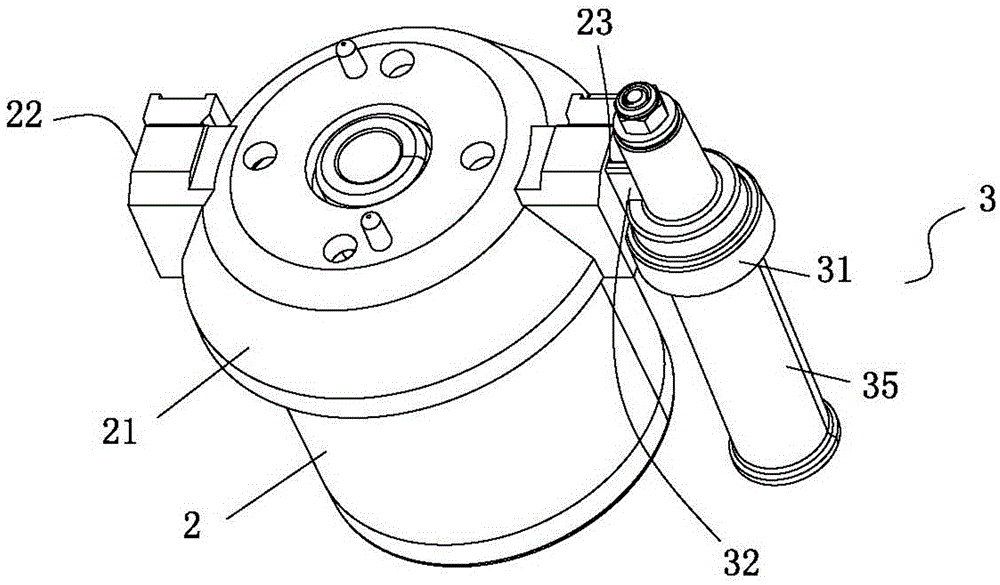

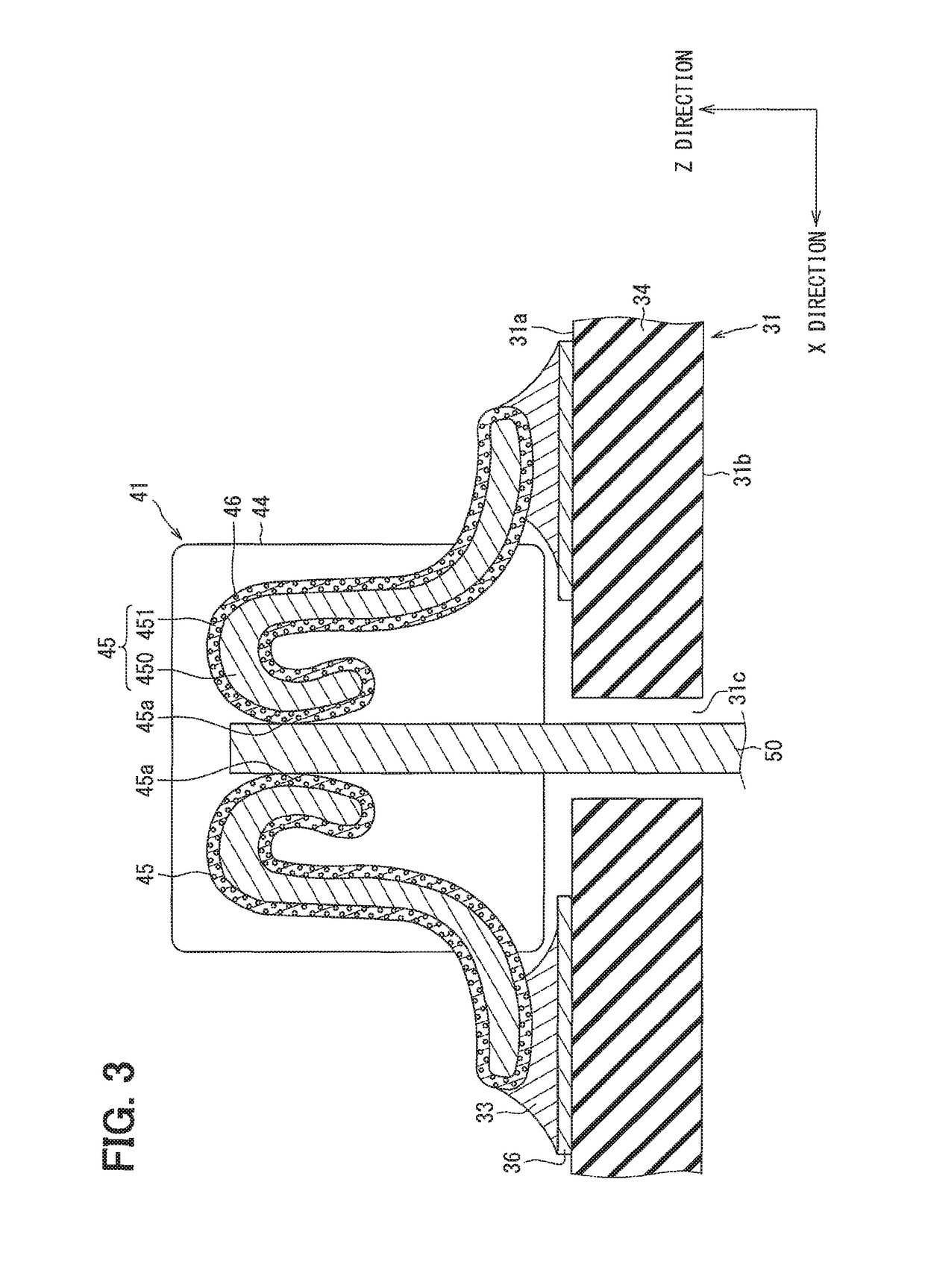

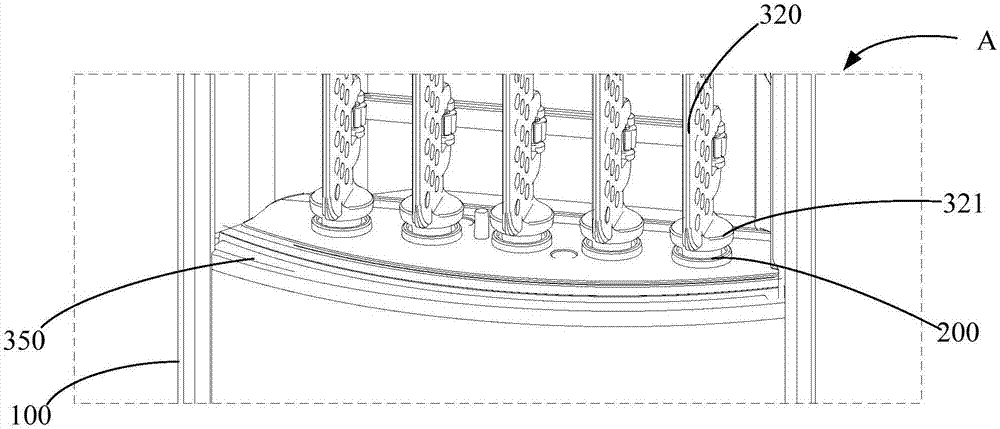

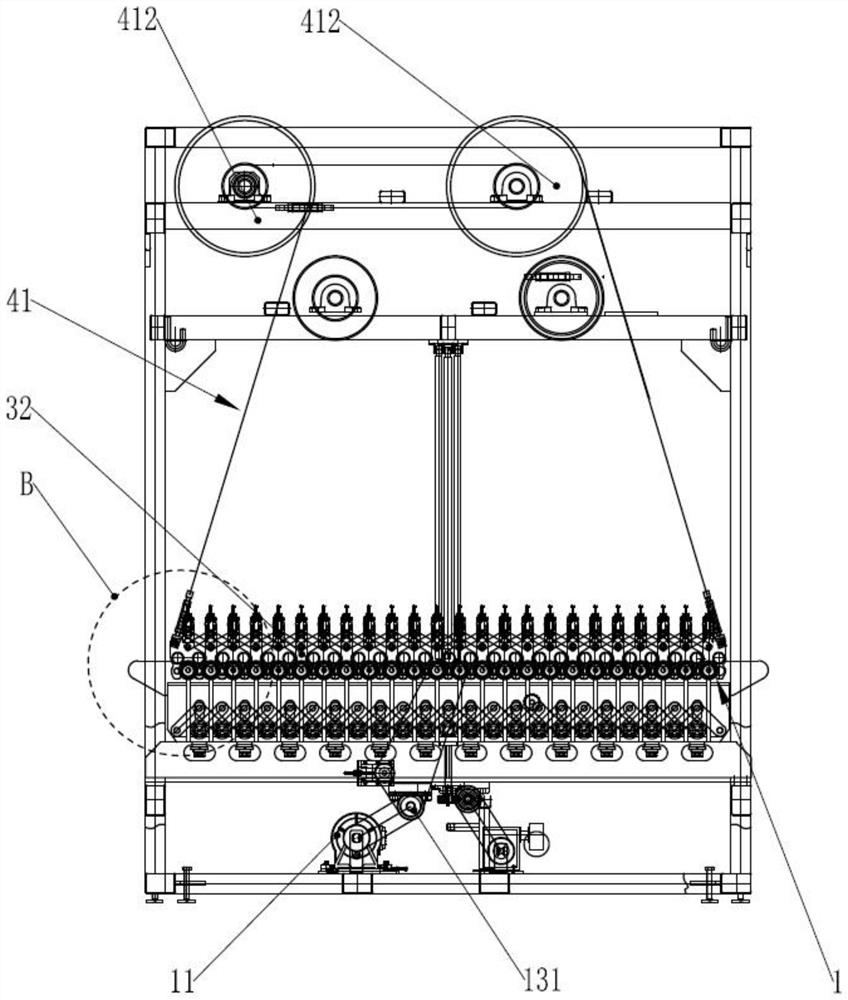

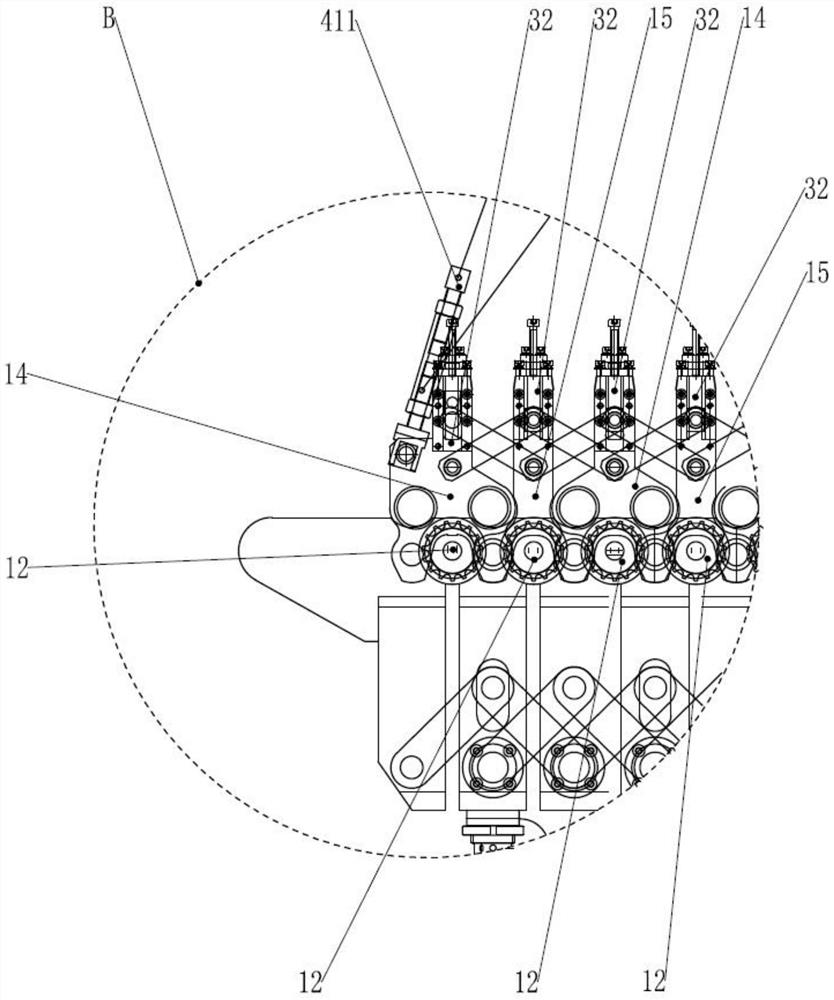

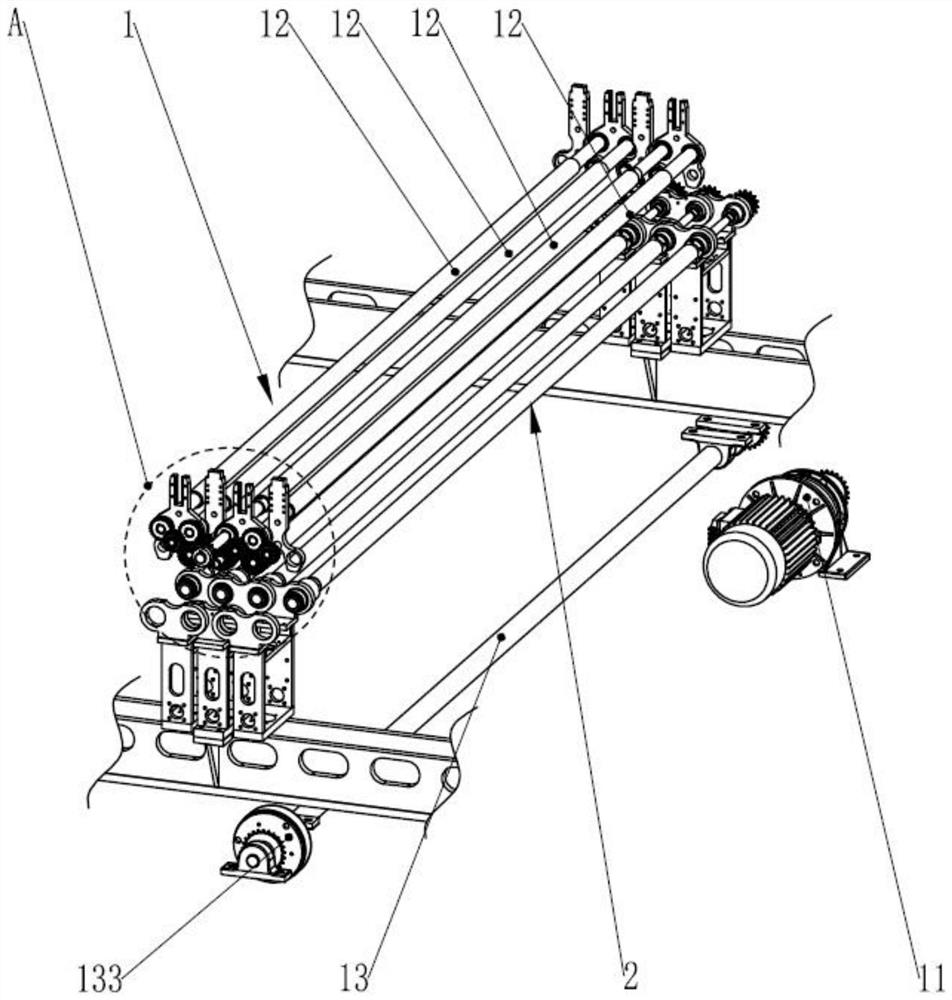

Excitation fluctuation precompressed multi-station compression moulding machine

InactiveCN101518920AConsistent structureFully exhaustedCeramic shaping apparatusEngineeringRepeatability

The invention discloses an excitation fluctuation precompressed multi-station compression moulding machine. Compression moulding units (1) are uniformly distributed and connected into a whole and are dragged by an intermittent mechanism (2) to carry out orderly transposition; a precompressed device (6) generates precompression under the compound effect of excitation and fluctuation; and a pressurizing device (7) converts the rotation of the power source into finalized compression moulding. Therefore, the compression moulding machine has the advantages that the machine overcomes the problems that the compression moulding is restricted by stroke and the compression moulding product has internal defects, the mechanical repeatability is uniform and reliable, the power distribution is reasonable and energy-saving, one machine has multifunction, multi-blocks can be generated by being pressed at one time and the compound compression moulding can be carried out.

Owner:高国强

Yarn wet-method waxing process

The invention discloses a yarn wet-method waxing process, which comprises the following steps: diluting molten wax with cold deionized water, adding acetic acid to regulate the pH value to 5 to 6, uniformly stirring, and adding into a cheese dyeing machine; performing post-treatment of yarns, dyeing, dehydrating and soaking the yarns in the cheese dyeing machine filled with the molten wax; and dehydrating and drying the soaked yarns at 100 to 120 DEG C. The process makes it is convenient to operate, and is applicable to processing of cellulosic fibers and blended yarns, particularly cotton yarns. The processed yarns can be directly used in weaving after being dried; and the dynamic friction value of the surface of the processed yarns is low, so that the hairiness phenomenon is eliminated effectively.

Owner:NANTONG UNIVERSITY

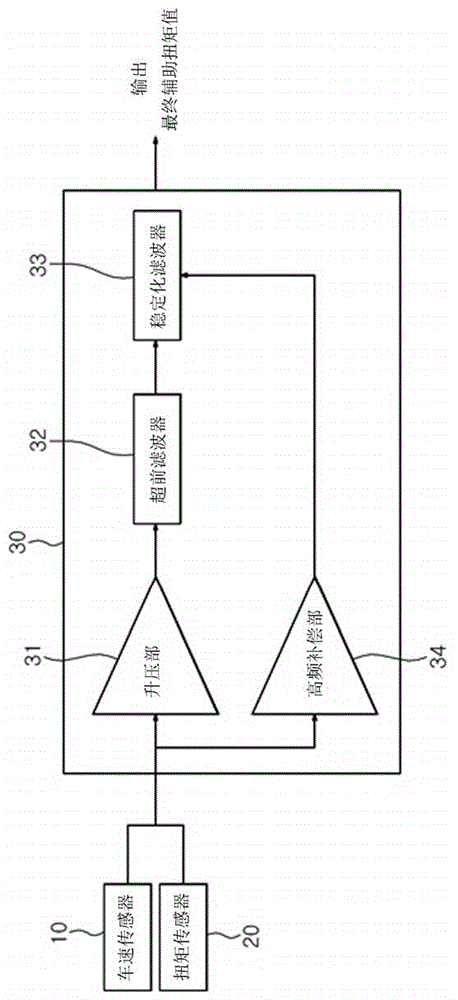

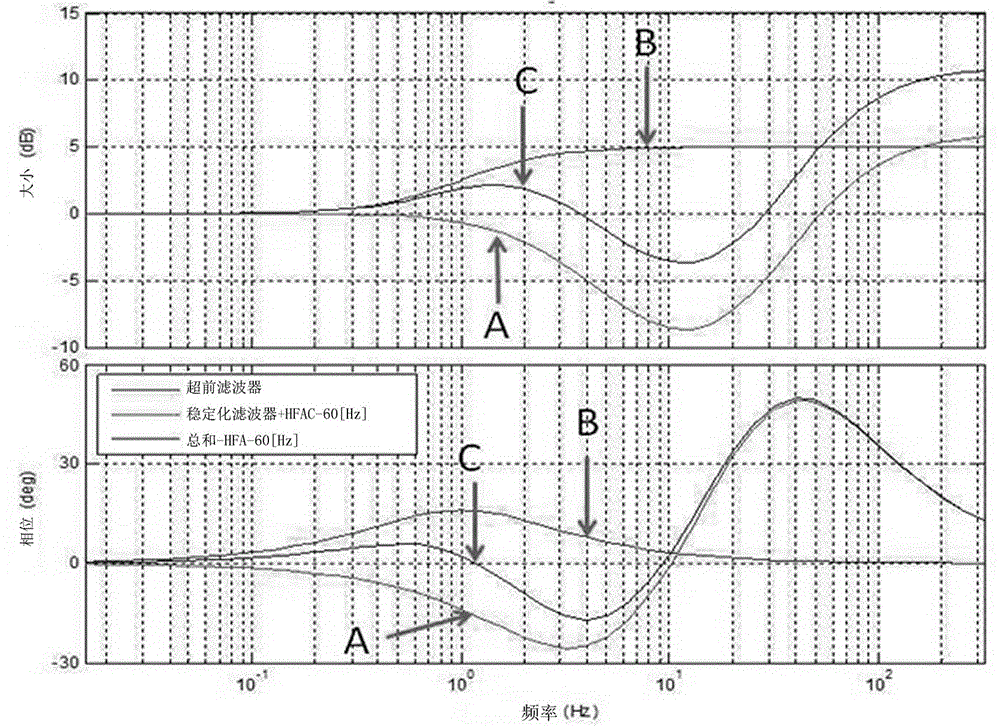

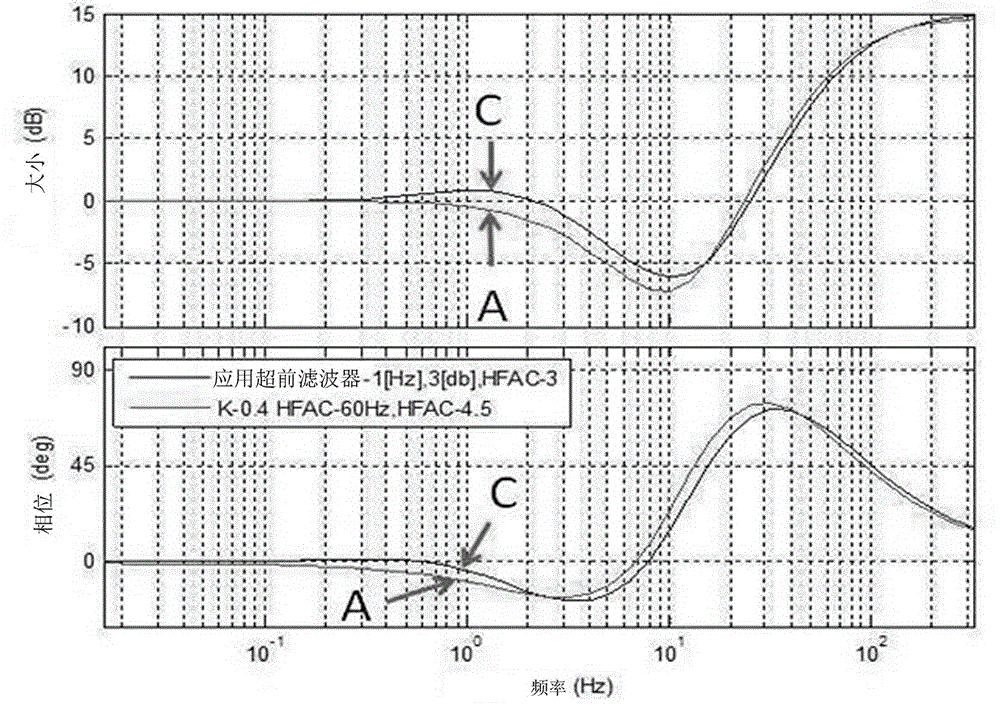

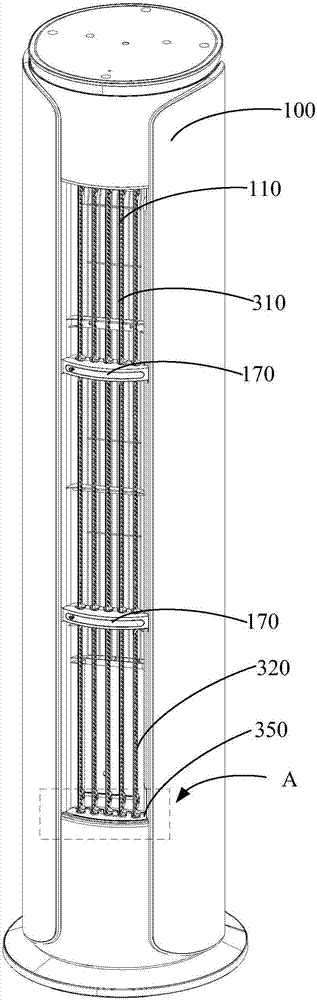

Compensation control apparatus of motor driven power steering system

ActiveCN105083370AHyporesponsiveness and delayReduce frictionSteering linkagesAutomatic steering controlSteering wheelPower steering

A compensation control apparatus of motor driven power steering may include: a torque sensor for measuring a driver's column torque inputted to a steering wheel; and a controller for generating an assist torque based on the column torque measured through the torque sensor, compensating for a phase margin in a low-frequency band for the generated assist torque, detecting a resonance frequency to attenuate resonance, and outputting a final assist torque.

Owner:HYUNDAI MOBIS CO LTD

Golf ball lubricant

InactiveUS7250009B2Improve featuresReduce kinetic frictionGolf ballsSolid ballsEngineeringGround propulsion

Owner:WEBER LAWRENCE J

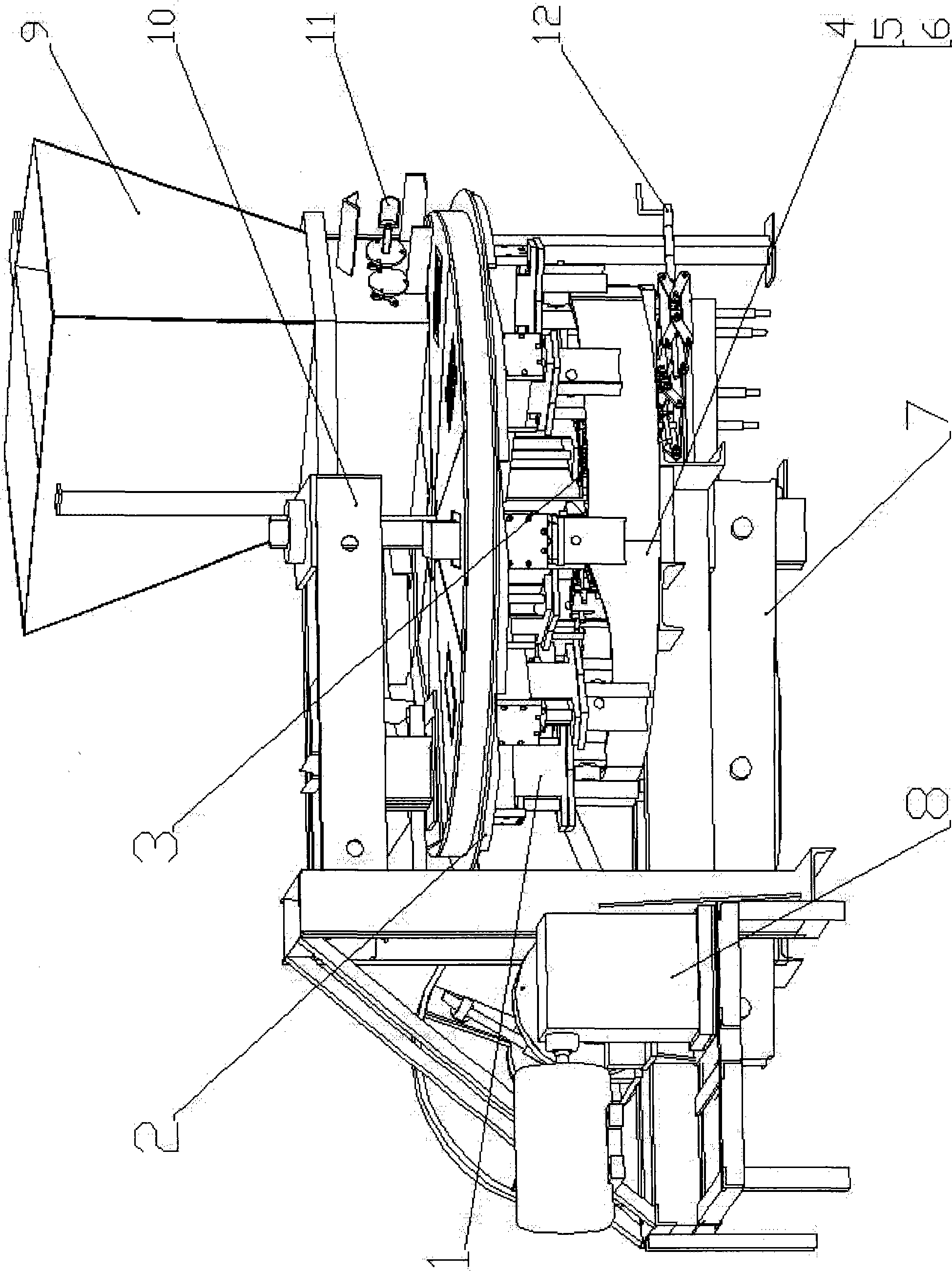

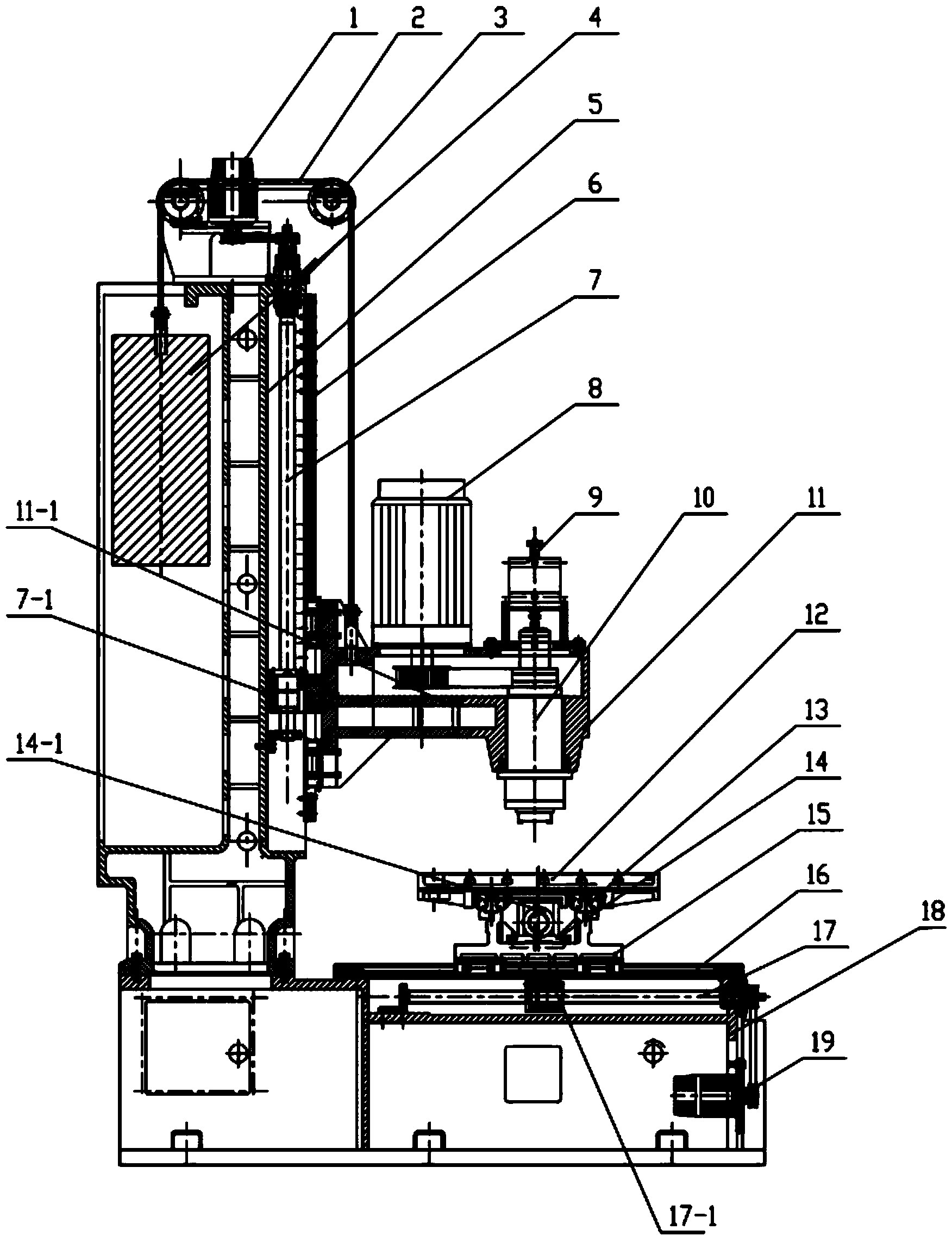

Digital controlled drill

InactiveCN103878409AIncrease Z-direction movement strokeReduce coefficient of frictionFeeding apparatusBoring/drilling componentsBall screwEngineering

The invention discloses a digital controlled drill which comprises a base, a Y-oriented servo motor, a Y-oriented rolling linear guide rail pair, a Y-oriented ball screw, a Y-oriented drive nut, a Y-oriented sliding table, an X-oriented servo motor, an X-oriented rolling linear guide rail pair, an X-oriented ball screw, an X-oriented drive nut, a working table, a Z-oriented servo motor, a Z-oriented ball screw, a drive nut, a Z-oriented main shaft box, a Z-oriented rolling linear guide rail pair and a stand column. The stand column is installed on the base, the Z-oriented servo motor is movably connected with the Z-oriented ball screw through a transmission mechanism so as to drive the Z-oriented ball screw to rotate, the Z-oriented ball screw is rotatably supported on the stand column, the drive nut is movably connected to the Z-oriented ball screw through threads, the Z-oriented main shaft box is fixedly connected with the drive nut, the Z-oriented rolling linear guide rail pair is arranged between the stand column and the Z-oriented main shaft box, and the working table is located below the Z-oriented main shaft box. According to the drill, moving strokes can be increased in the X direction, the Y direction and the Z direction, the machining range of workpieces is widened, meanwhile, the electric power loss amount can be reduced, cost is saved, and precise positioning and machining of the workpieces can be achieved.

Owner:江苏映彤机械设备有限公司

V-ribbed belt

InactiveUS7896767B2Good lookingSuppresses noise generationV-beltsRopes and cables for vehicles/pulleyEngineeringPulley

Owner:BANDO CHEM IND LTD

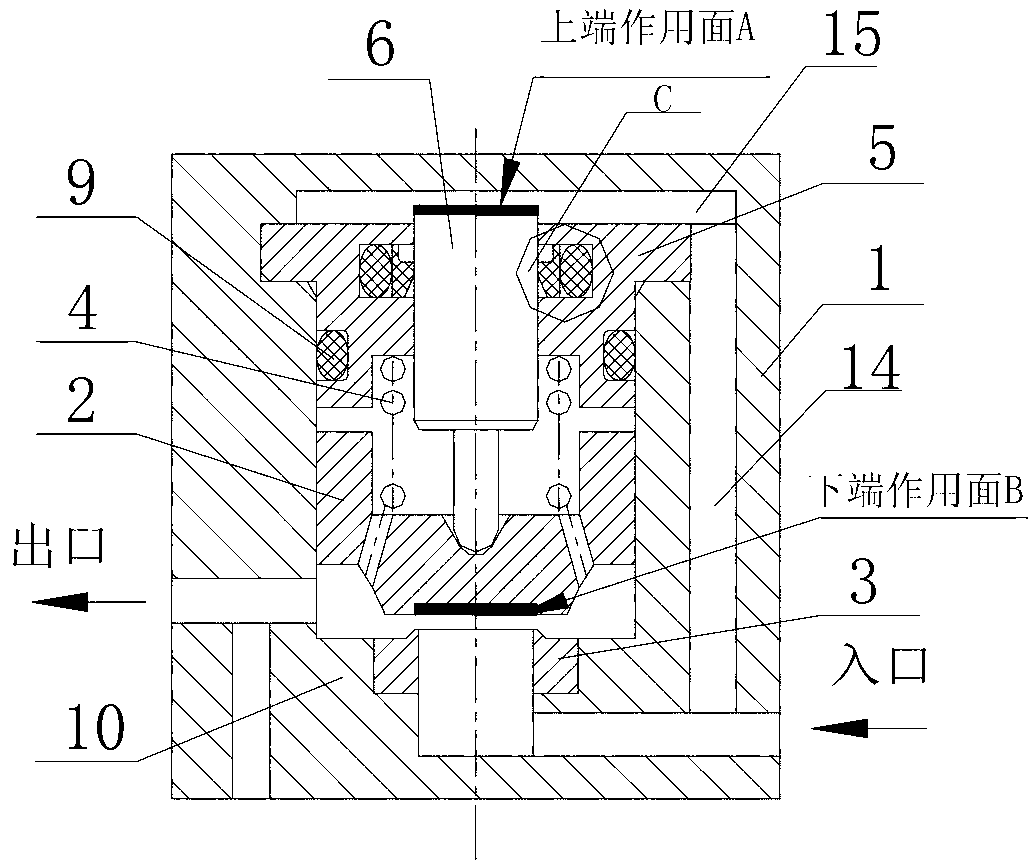

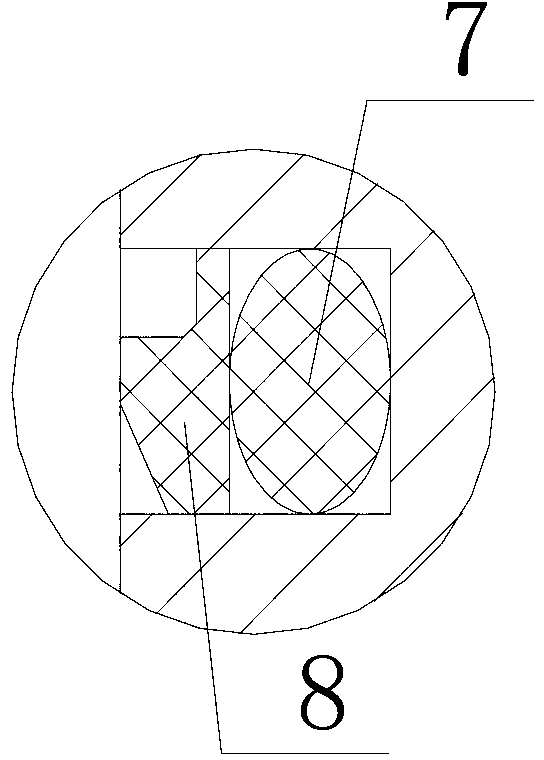

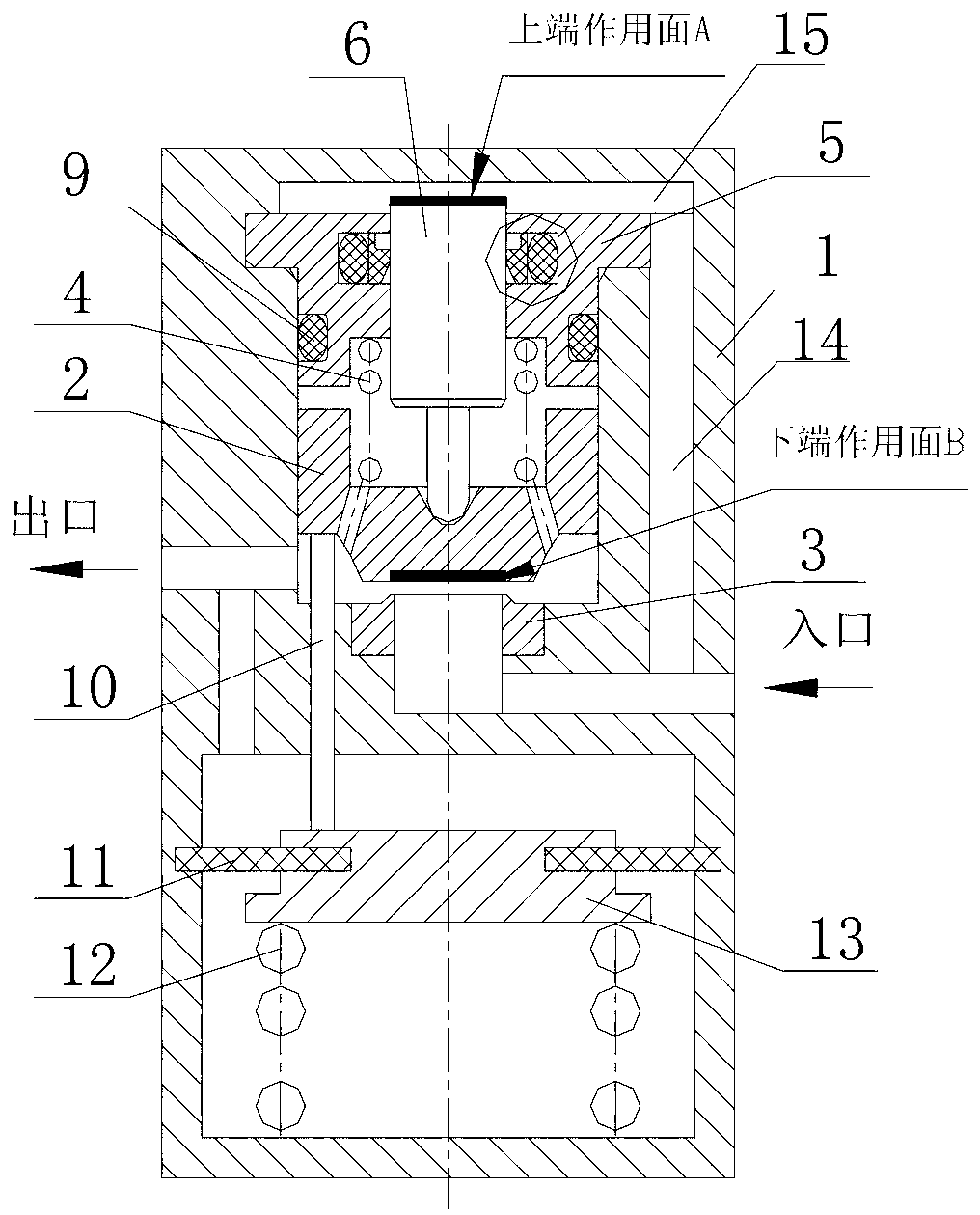

Forward low-friction unloading gear for reducing valve and reducing valve

ActiveCN103016835AImprove compatibilityWork reliablyValve members for absorbing fluid energyEqualizing valvesInlet pressureLow friction

The invention relates to a forward low-friction unloading gear for a reducing valve. The forward low-friction unloading gear comprises an unloading ring, an unloading pole, an inlet pressure unloading flow passage and a seal assembly, wherein the unloading ring is fixedly arranged in a valve body and between the valve body and a valve core, a cavity is arranged between the unloading ring and the valve body, the unloading pole is arranged in the unloading ring in a sliding and matched way, the upper end face of the unloading pole is arranged in the cavity, the lower end face of the unloading pole is in contact with the valve core, the areas of the lower end face of the valve core and the upper end face of the unloading pole are equal, assistant springs are arranged between the unloading ring and the valve core, the inlet pressure unloading flow passage is arranged inside the valve body, one end of the inlet pressure unloading flow passage is communicated with an inlet, and the other end of the inlet pressure unloading flow passage is communicated with the cavity. The invention provides the unloading gear capable of enhancing the outlet pressure regulation precision of the reducing valve. The unloading gear disclosed by the invention has the advantages of simple structure, small frictional resistance, convenience in processing and manufacturing, and the like; and the unloading gear is capable of eliminating the influence to the regulation precision of the reducing valve, brought by the inlet pressure change and improving the outlet pressure regulation precision of the reducing valve.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

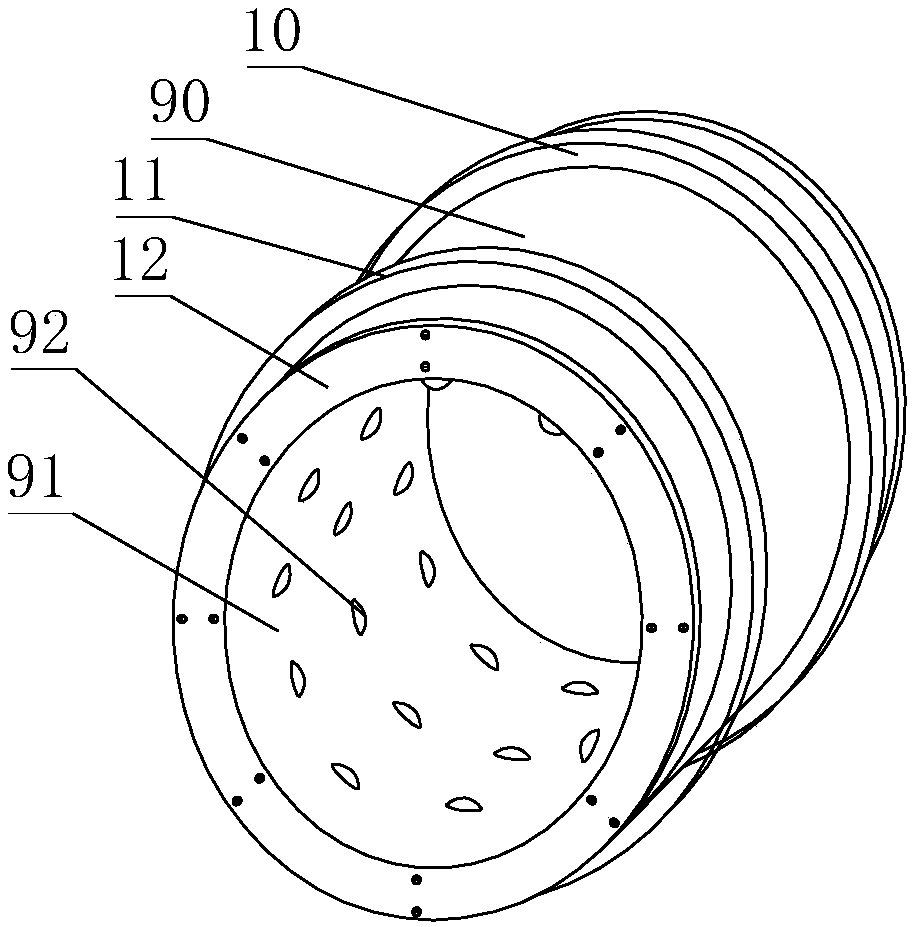

Wire paying-off machine

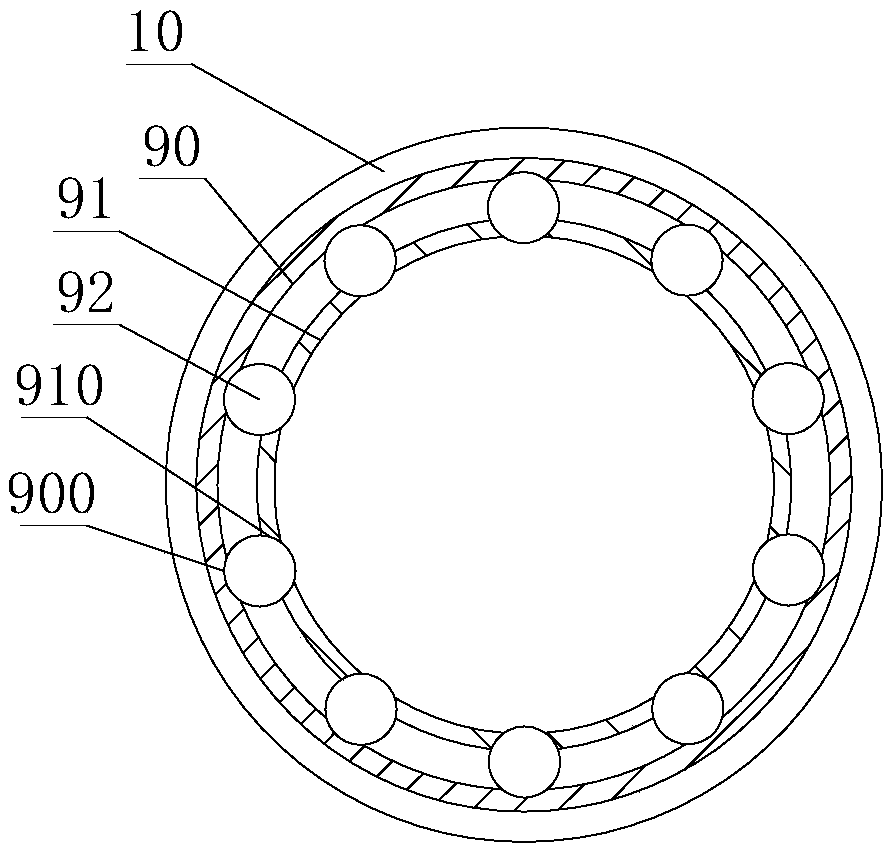

The invention discloses a wire paying-off machine comprising a rack, a winding shaft assembly, a supporting rod, a sliding rod, a sliding block, a mounting block and a wire passing cylinder. The winding shaft assembly and the supporting rod are arranged on the rack, the sliding rod is fixedly connected with the supporting rod, the sliding block is slidably connected with the sliding rod, the mounting block is connected with the sliding block, a connecting through hole is formed in the mounting block, the axis of the connecting through hole is perpendicular to the plane where the supporting rodand the sliding rod are located, and the wire passing cylinder is mounted in the connecting through hole in a sleeved mode; the wire passing cylinder comprises an outer layer cylinder body, an innerlayer cylinder body, a roller and a cover ring; and the inner layer cylinder body is sleeved with the outer layer cylinder body, the roller is arranged between the outer layer cylinder body and the inner layer cylinder body, the roller is protruded out of the inner wall of the inner layer cylinder body, the roller can rotate relative to the outer layer cylinder body and the inner layer cylinder body, and the cover ring is fixedly connected with the end faces of the inner layer cylinder body and the outer layer cylinder body. According to the wire paying-off machine, the pressure between a wireor a cable and the wire passing cylinder is dispersed by sliding of the sliding block on the sliding rod and rotating of the roller, thus dynamic friction between the wire or the cable and the wire passing cylinder is lowered, and then abrasion of the wire or the cable is reduced.

Owner:安徽双马机械设备有限公司

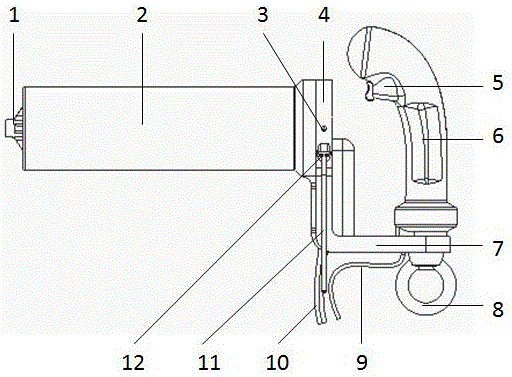

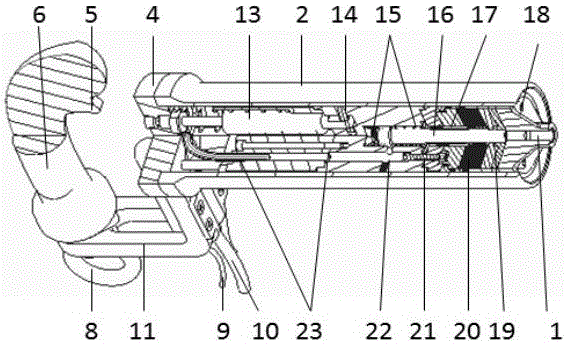

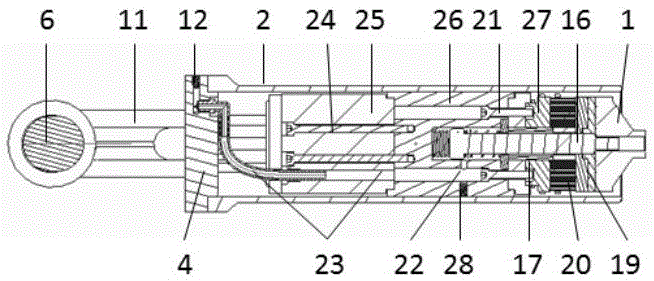

Cooling device of small-sized electromagnetic riveter and implementation method thereof

The invention relates to a cooling device of a small-sized electromagnetic riveter and an implementation method of the cooling device of the small-sized electromagnetic riveter. Considering that a coil generates heat during single discharge of the electromagnetic riveter, after repeated riveting discharge, the heat generated by the work coil accumulates, the temperature becomes lower gradually from the center of the coil to the edge of the coil in the radial direction, the insulating layer of the portion, generating most heat, of the coil is prone to breakdown, and then the work coil is damaged. According to the cooling device of the small-sized electromagnetic riveter, cooling gas is fed into the riveter through a guide pipe, the cooling gas enters a cooling air channel and then is guided to the surface of a mandrel through a cooling air inlet formed between the cooling air channel and the mandrel, the mandrel is sleeved with a multi-groove-type coil sleeve capable of sliding relative to the mandrel in a reciprocating manner, the cooling gas is guided to surface of the work coil in the radial direction of the work coil finally along the inner surface of the multi-groove-type coil sleeve, and then the purpose of cooling the work coil is achieved; and the gas is discharged out of the riveter after cooling from a gap reserved at the front end of the riveter.

Owner:FUZHOU UNIV

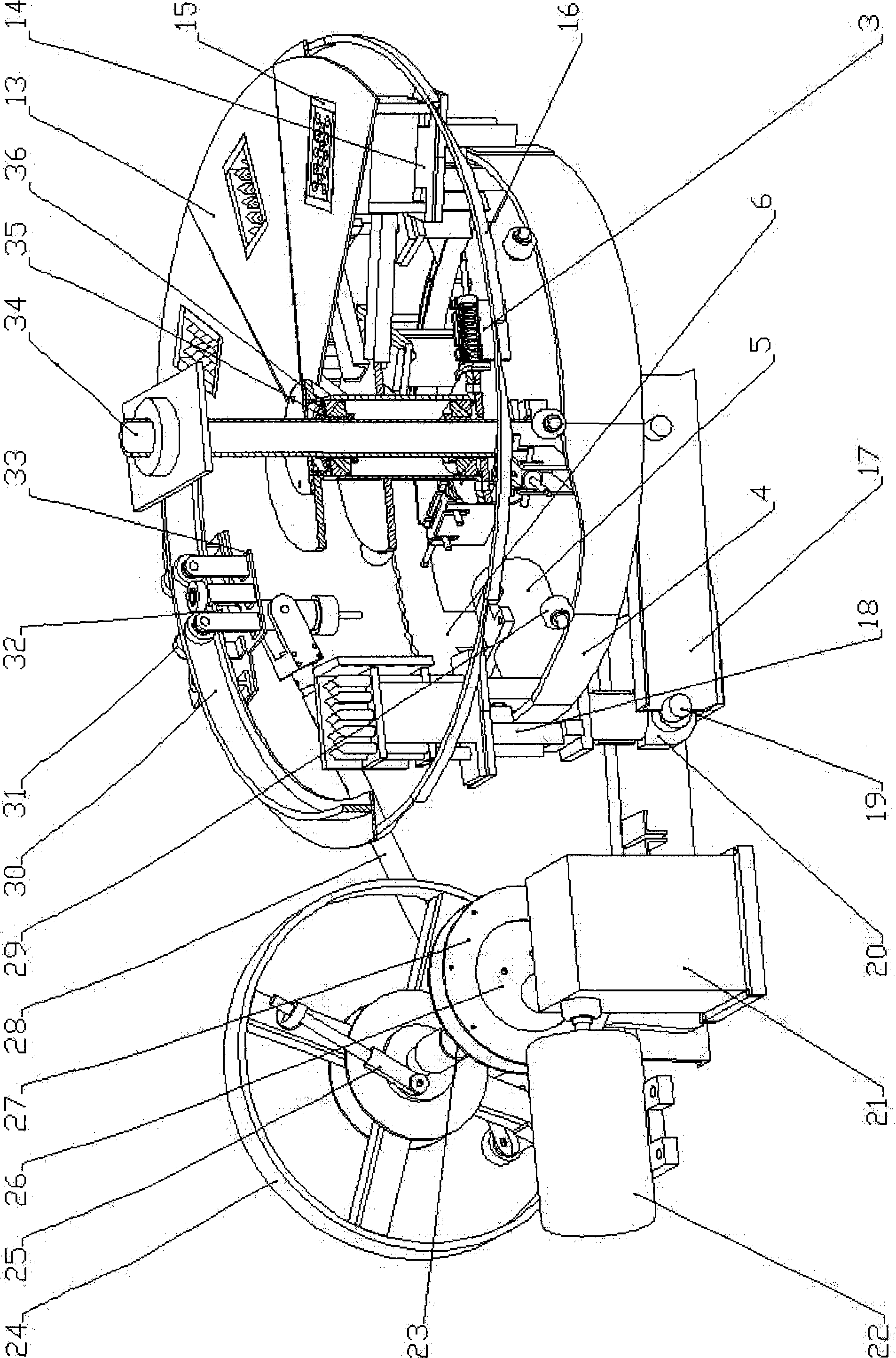

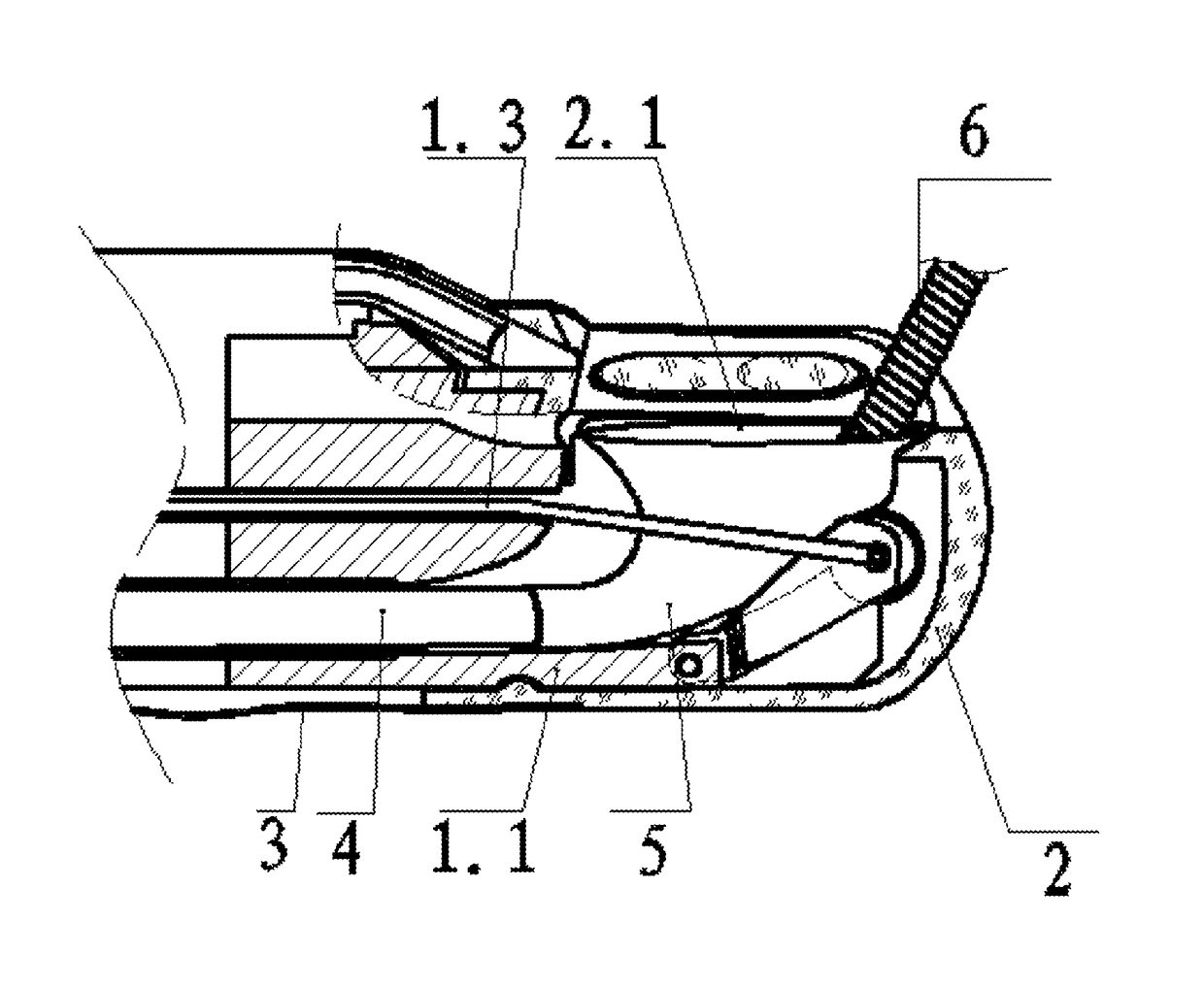

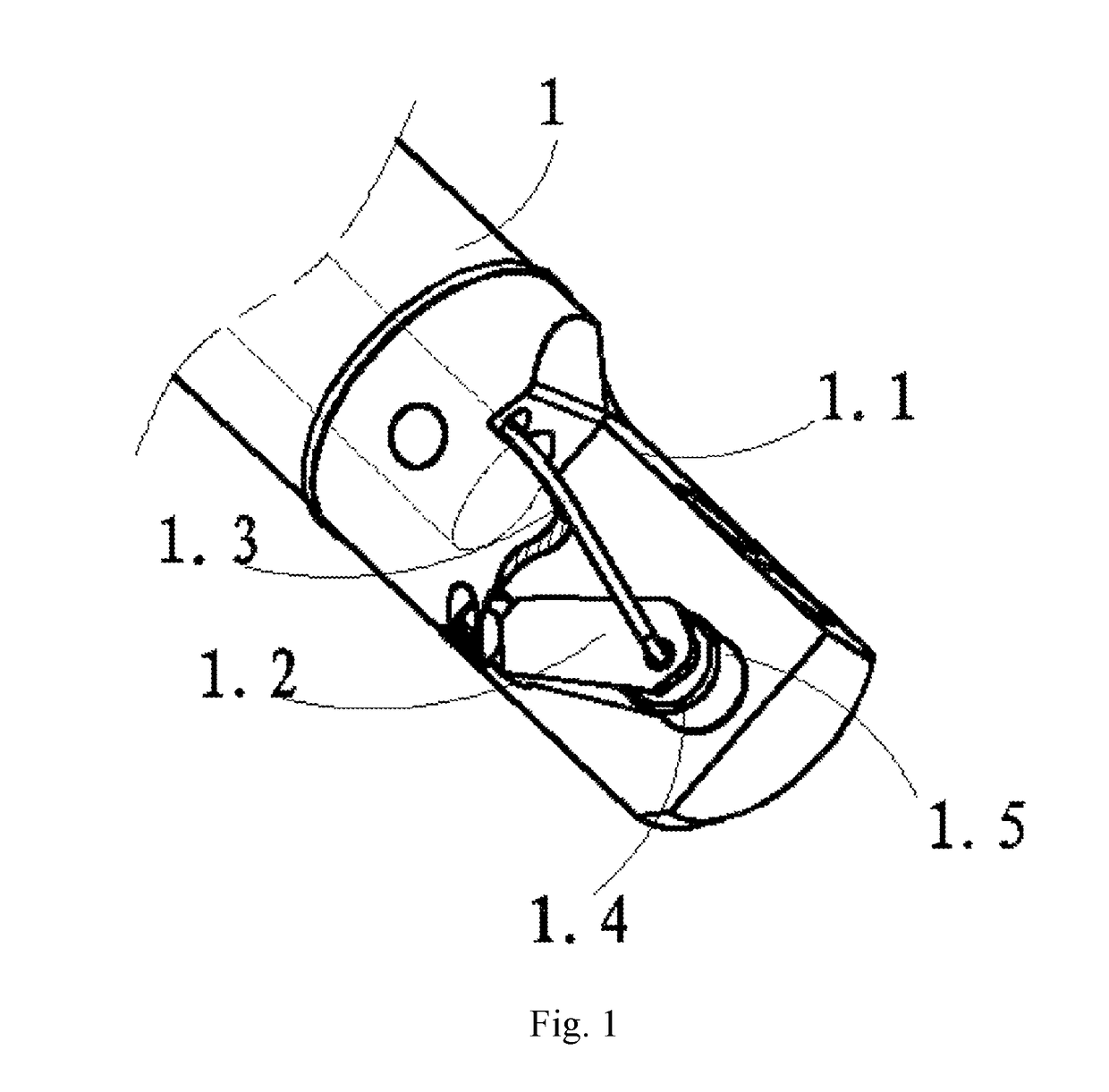

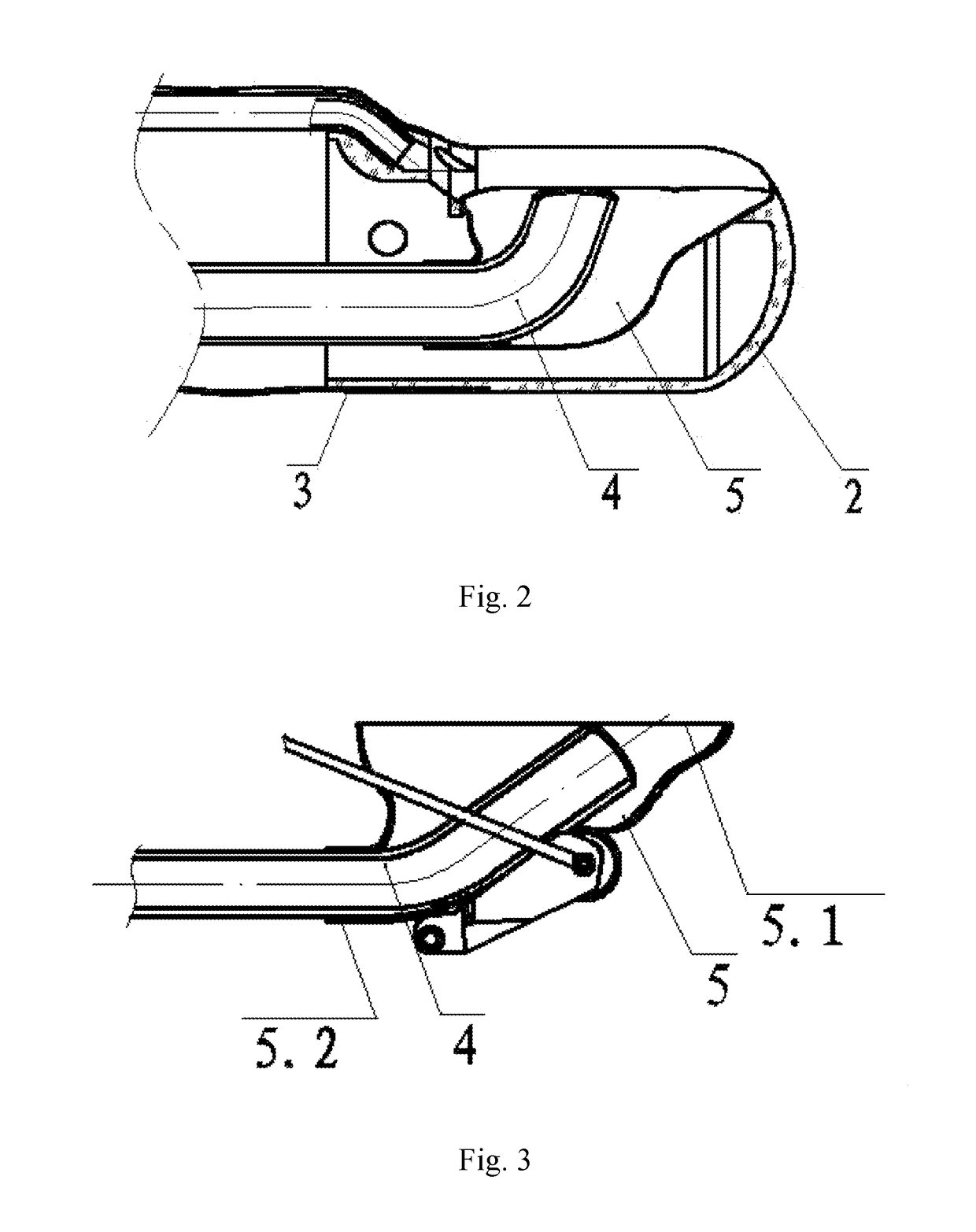

Duodenoscope Protected With Disposable Consumables

ActiveUS20170325666A1Reduce kinetic frictionAvoid cross infectionGastroscopesOesophagoscopesForcepsThin membrane

A duodenoscope protected with disposable consumables is provided. An insertion portion of a duodenoscope body (1) is covered with a cuff (3). A disposable forceps passage tube (4) is inserted into a tube of the duodenoscope body (1). A distal end of the duodenoscope body (1) is covered with an end cap (2) which is integrally connected to the cuff (3) and the disposable forceps passage tube (4). An elongated opening (2.1), which is of the same shape as the opening of a head end (1.1) of the duodenoscope body (1), is formed in a side face of the end cap (2). A forceps-lifting unit (1.2) is disposed in the head end (1.1) of the duodenoscope body (1). The end cap (2) is made of a transparent elastic material. A soft connection port (5) is disposed in the elongated opening (2.1) of the end cap (2). The soft connection port (5) is shaped like a smoking pipe and made of an elastic film. A large-orifice end of the soft connection port (5) is glued to the elongated opening (2.1) of the end cap (2), while a small-orifice end (5.2) thereof sleeves and is glued to a distal end of the disposable forceps passage tube (4). A pulley (1.4) is disposed on the head of the forceps-lifting unit (1.2), and a groove (1.5) is formed in the periphery of the pulley (1.4). The duodenoscope protected with disposable consumables can protect both the external surface of the duodenoscope and the internal surface of the tube.

Owner:SHENYANG SHENDA ENDOSCOPE

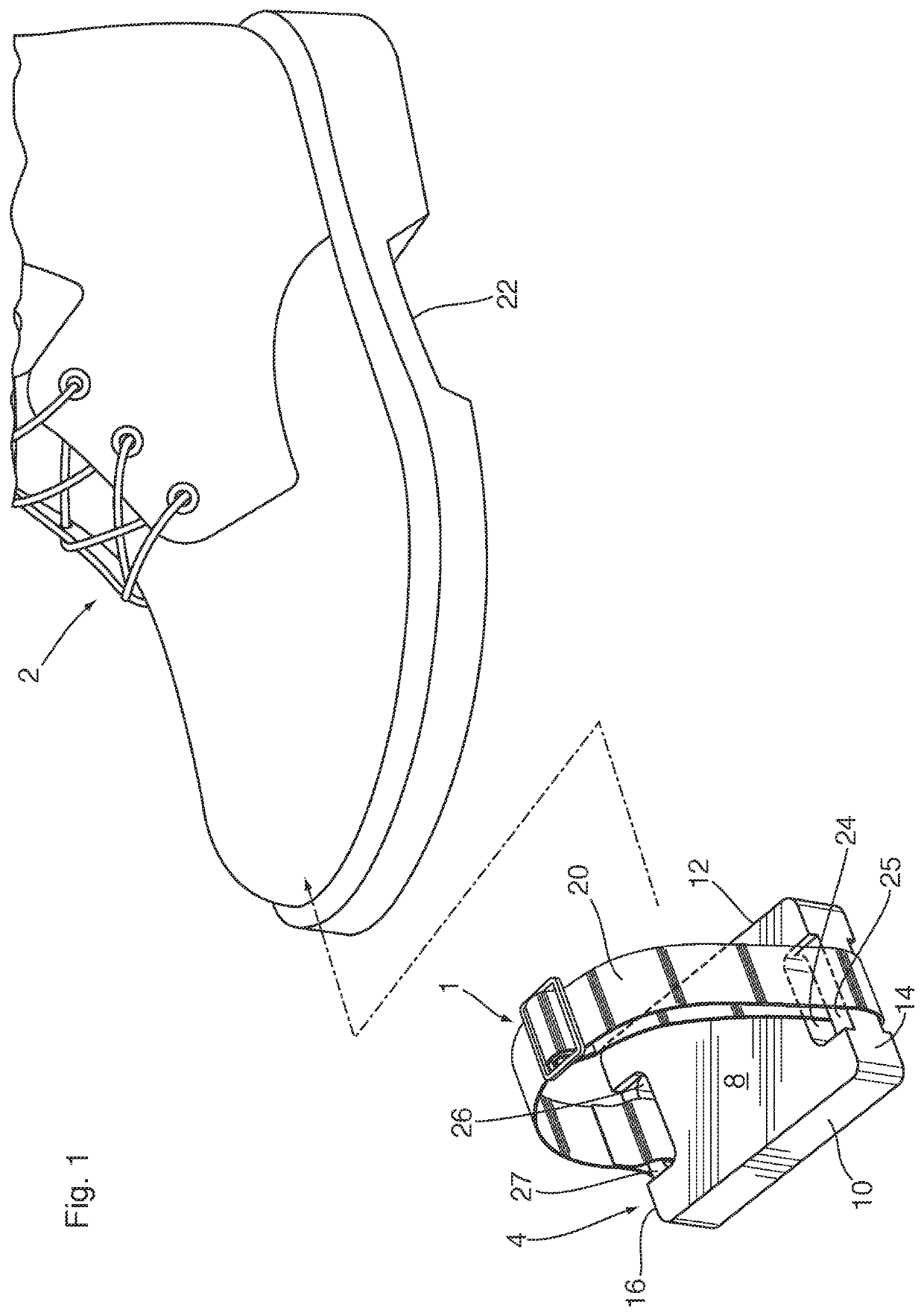

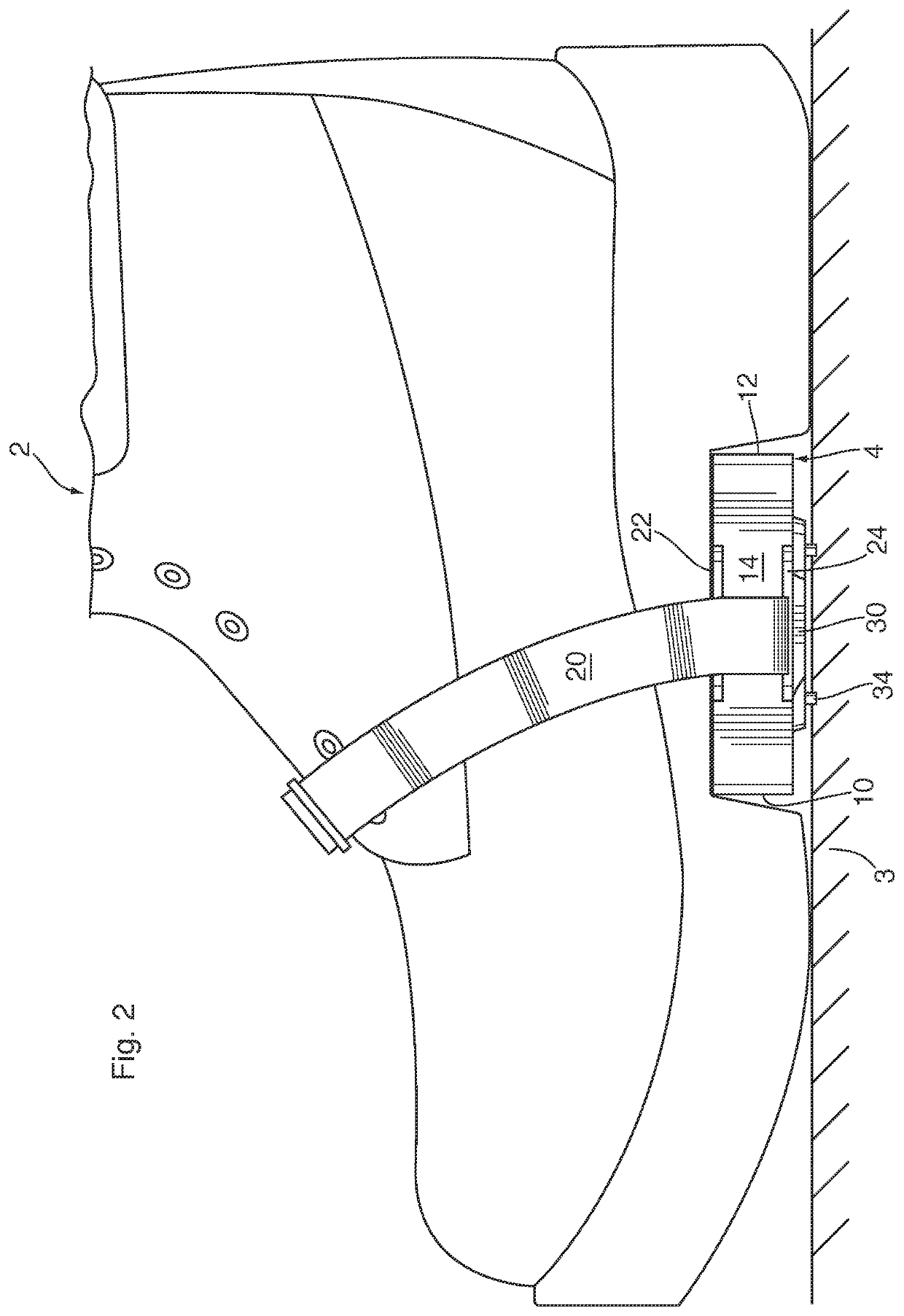

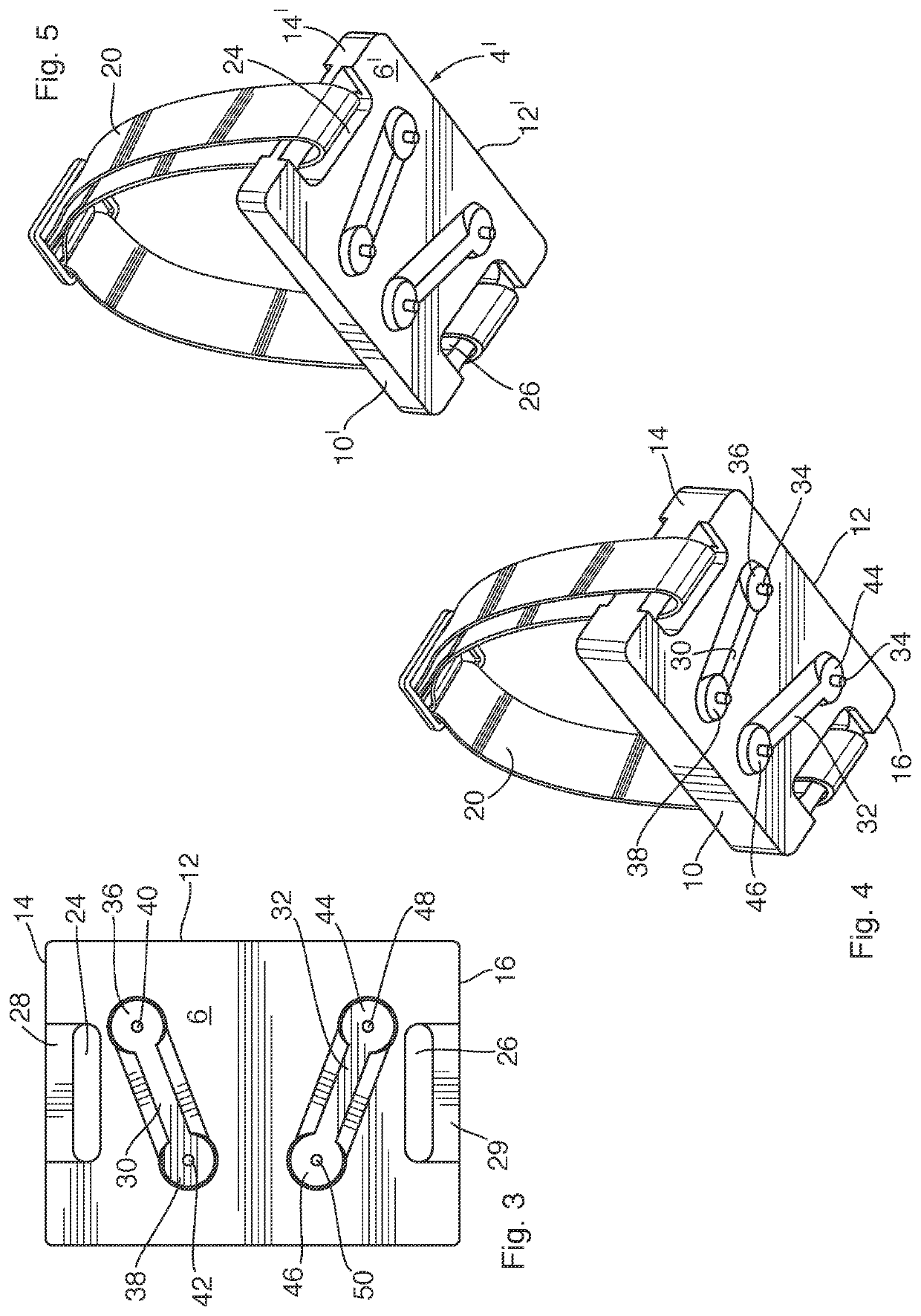

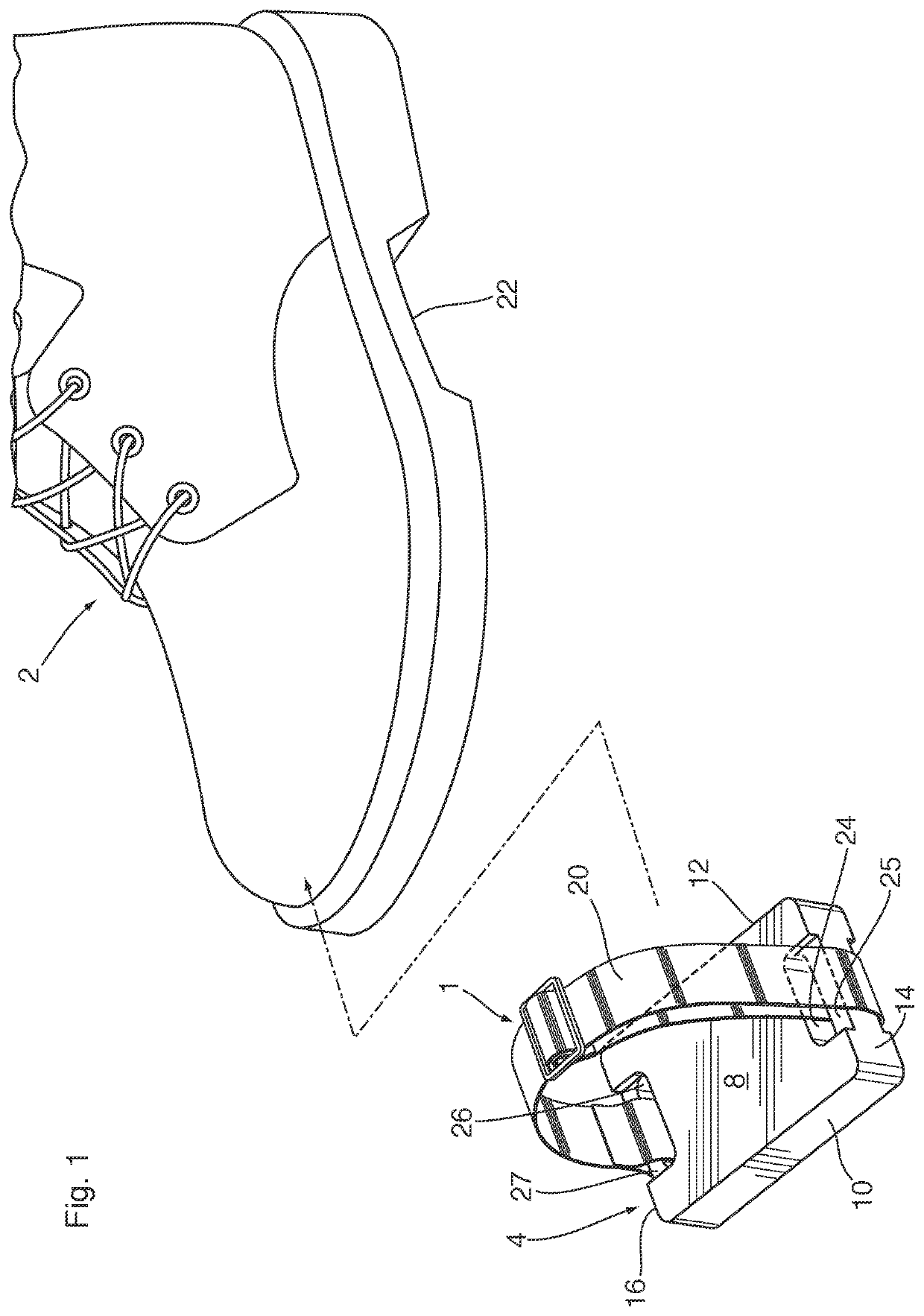

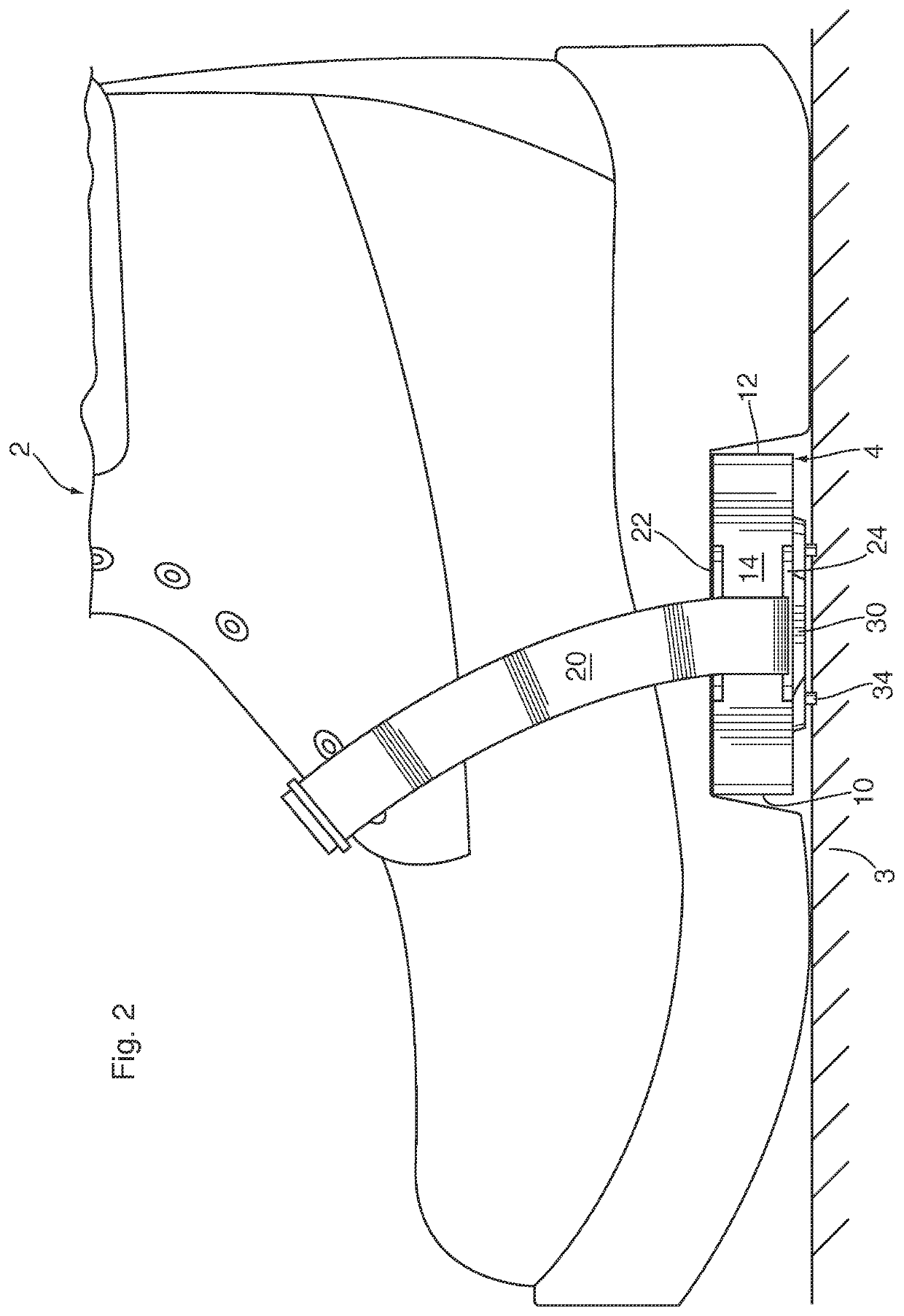

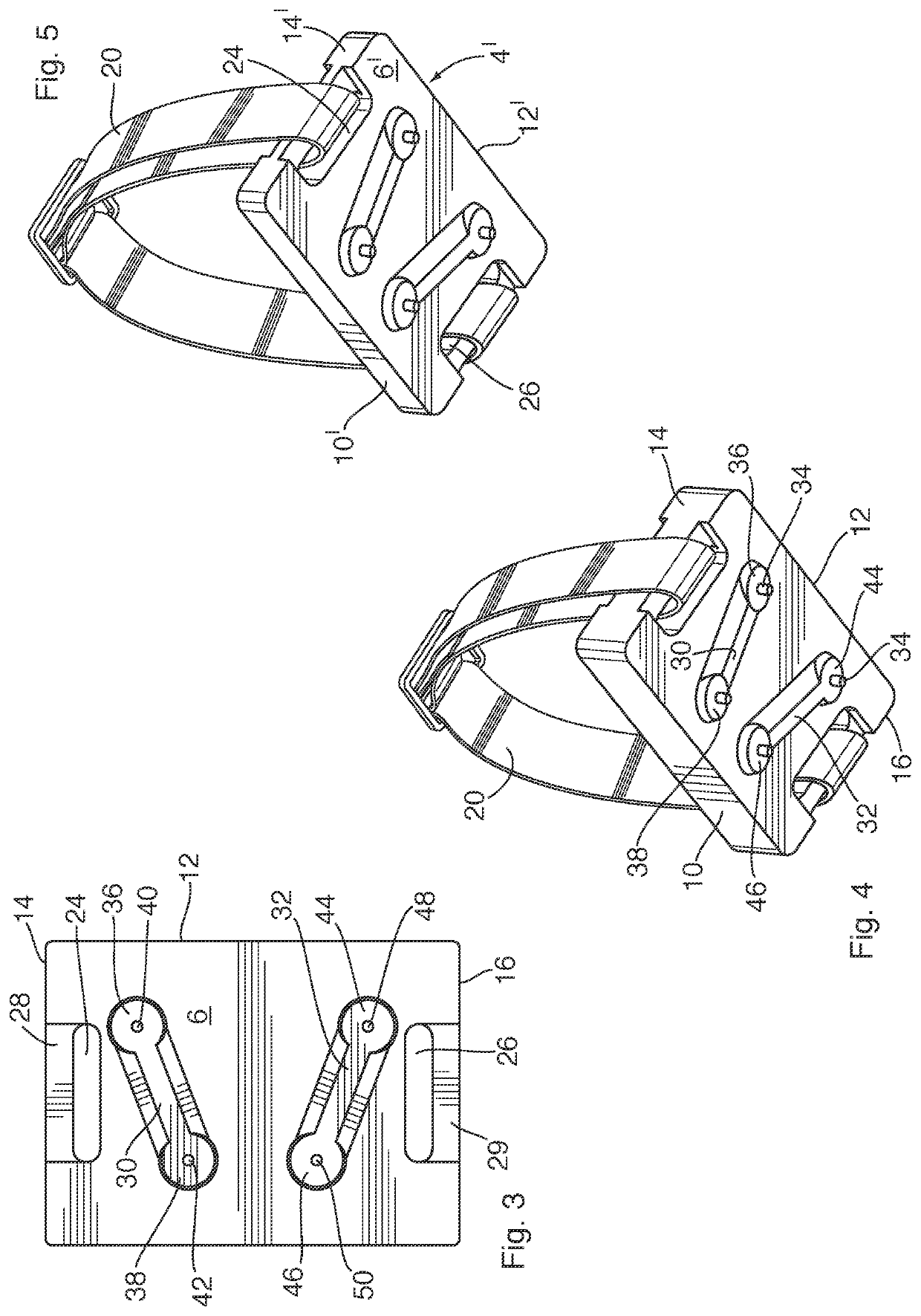

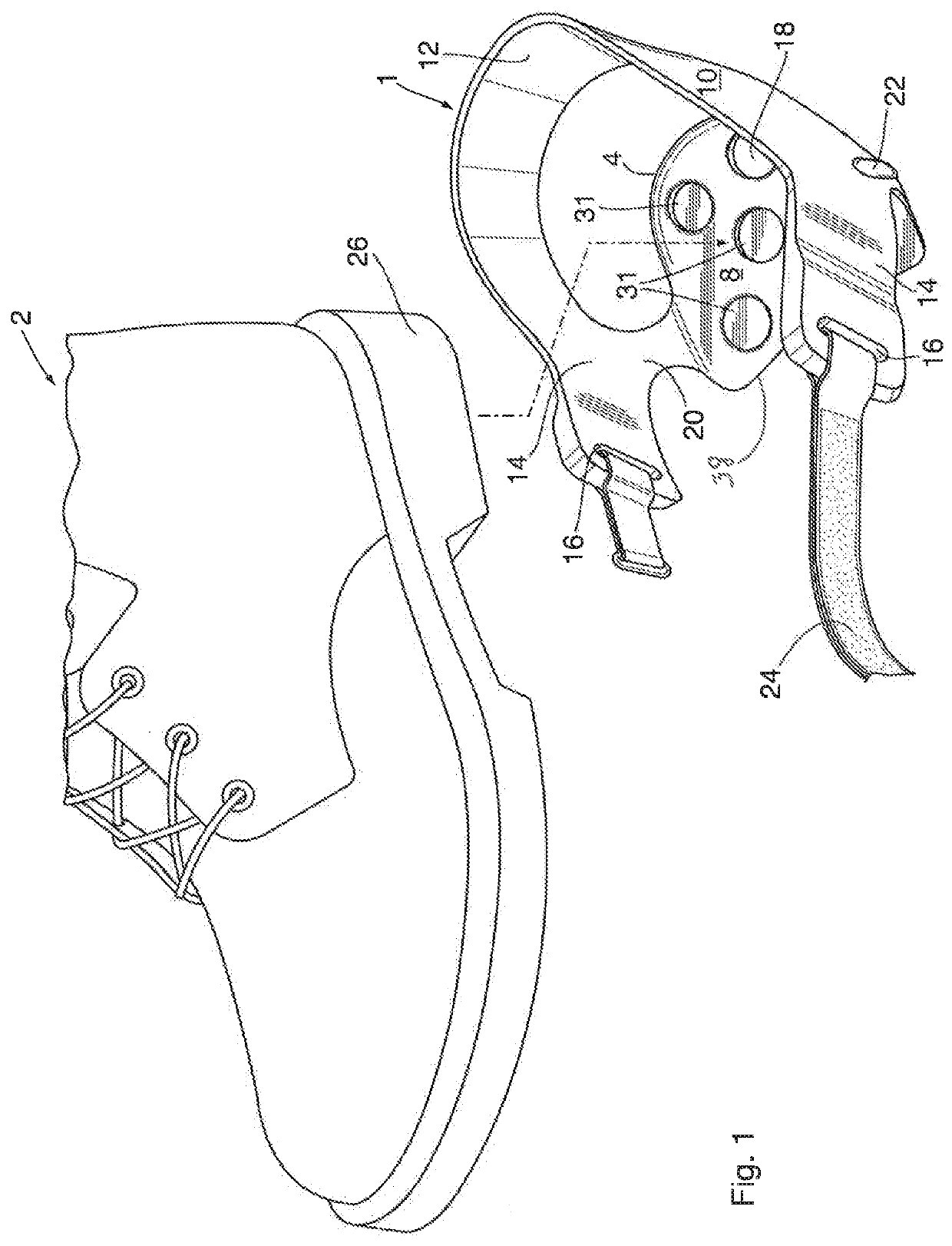

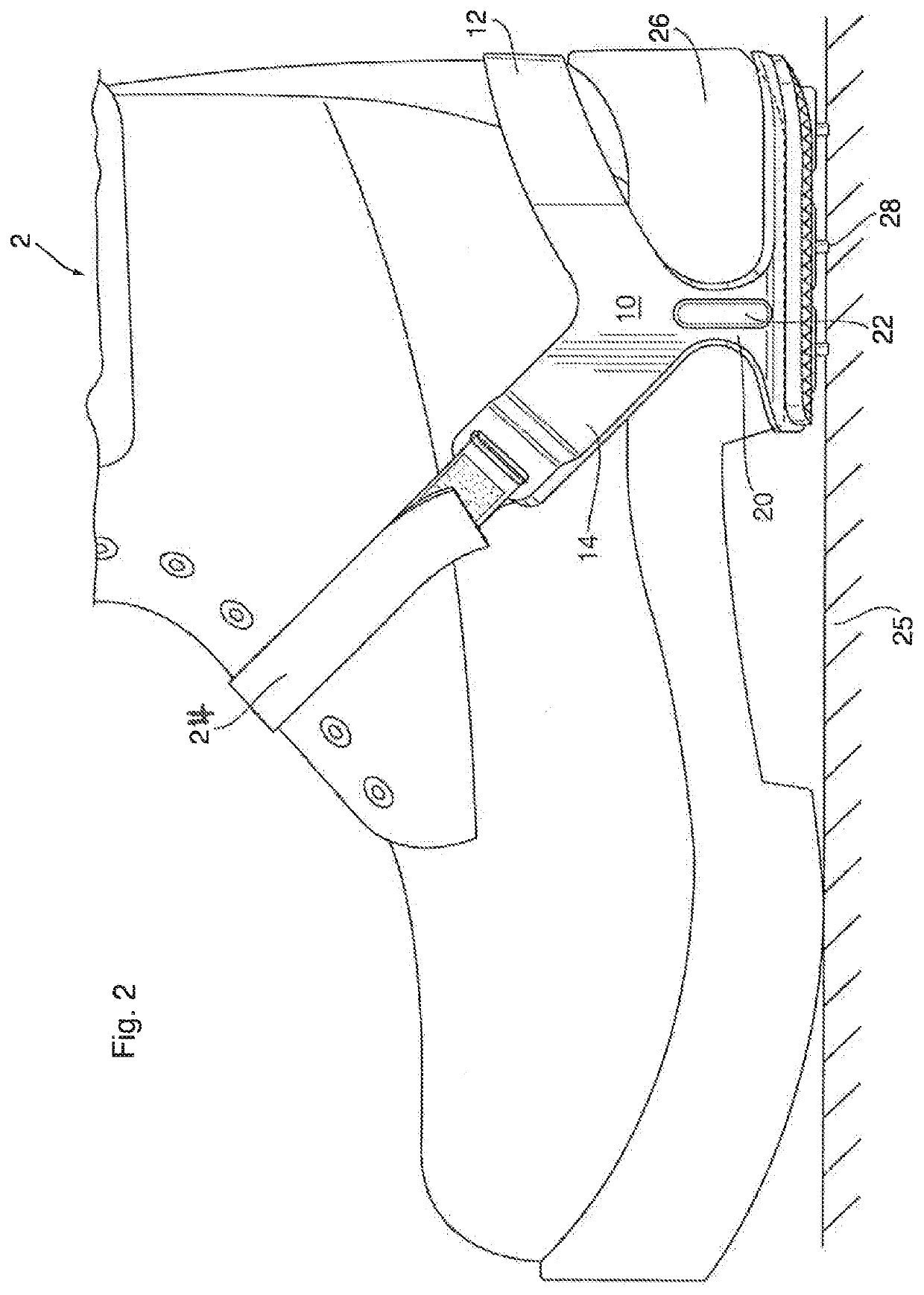

Mid-sole traction device

ActiveUS20220031025A1Lower coefficient of dynamic frictionProtect the surfaceFasteningsRubber materialEngineering

A mid-sole traction device for a shoe or a boot comprises a traction platform formed of a flexible rubber material. The platform has a first face for contacting a ground surface and a second face for attachment to a mid-sole of the shoe / boot. The first face is spaced from the second face. First and second protrusions are formed on the first face. The first protrusion has first and second ends, each of which defines an opening for receiving a spike. The second protrusion has first and second ends, each of which defines an opening for receiving a spike. The second protrusion is separate and spaced from the first protrusion. A first slot is formed in the platform and is located near a first peripheral edge of the platform for receiving a strap. A second slot is formed in the platform near a second peripheral edge for receiving a strap.

Owner:DENTEC SAFETY SPECIALISTS INC

Convenient-to-disassemble type assembling mechanism for yarn splitting device

A convenient-to-disassemble type assembling mechanism for a yarn splitting device relates to the technical field of textile and comprises a yarn storing bobbin, a yarn storing bobbin dustproof cover and the yarn splitting device. The upper end of the yarn storing bobbin is covered by the yarn storing bobbin dustproof cover, the yarn splitting device comprises a core rod and a yarn splitting dustproof cover, the yarn splitting dustproof cover is in a barrel shape and covers the core rod, and assembling devices are respectively manufactured on the yarn storing bobbin dustproof cover and the yarn splitting dustproof cover, the yarn splitting device is detachably arranged on the yarn storing bobbin dustproof cover through the assembling devices, the assembling devices on the yarn storing bobbin dustproof cover are arranged at the two radial ends of the yarn storing bobbin dustproof cover, and the assembling devices are in a drawn clamping-connection mode through clamping connection convex ribs and clamping-connection grooves. The yarn splitting device can be conveniently clamped with and disassembled from the yarn storing bobbin dustproof cover. When the rotating direction of the yarn storing bobbin is changed, the yarn splitting device is disassembled from one side of the yarn storing bobbin dustproof cover and is assembled to the assembling devices on the other side of the yarn storing bobbin dustproof cover, and then the yarn splitting device is quick to assemble and disassemble. After startup or yarn breaking in the halfway, yarns can be quickly wound on the yarn storing bobbin and a yarn splitting sleeve. Thus, work time is saved, the work efficiency is improved, and the weaving cost is reduced.

Owner:DONGGUAN JINFU HARDWARE MACHINERY +1

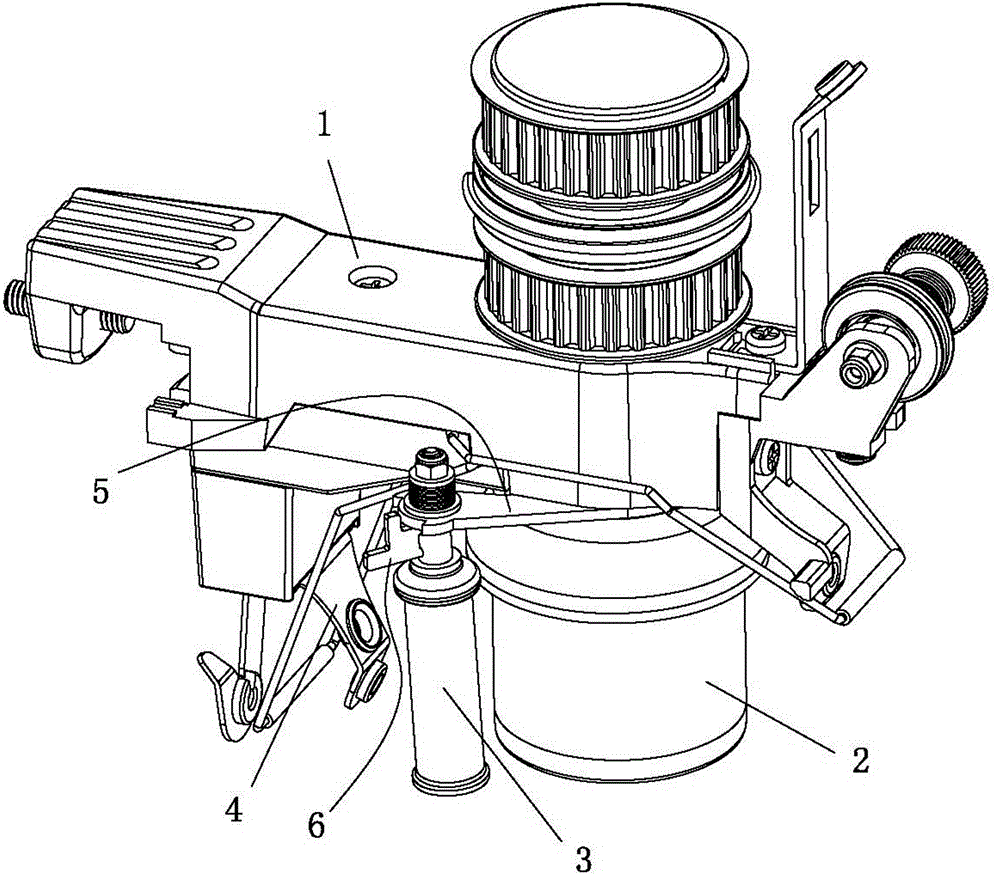

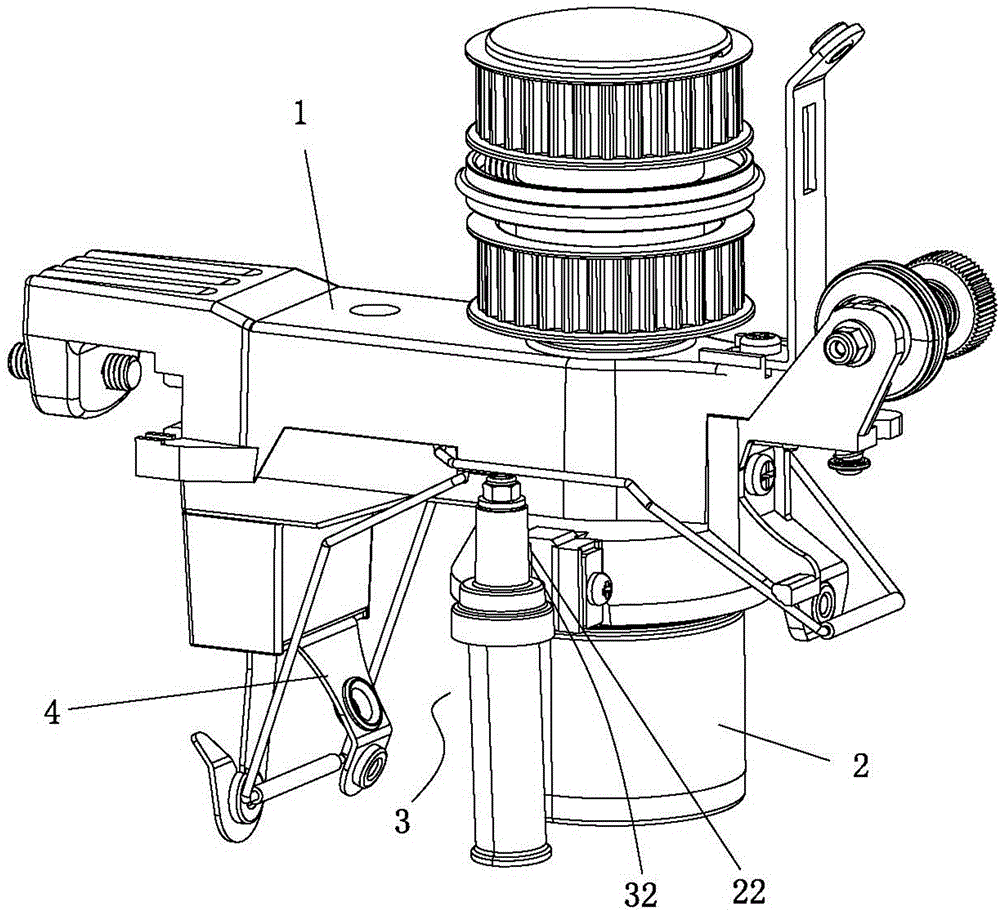

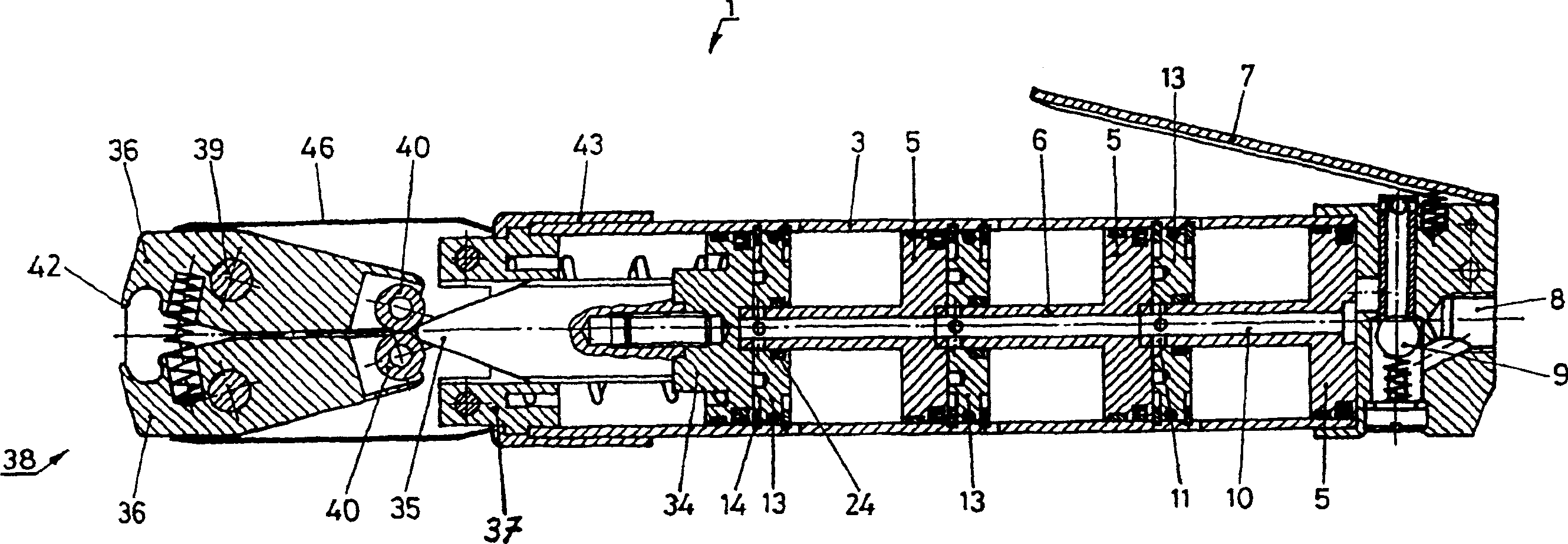

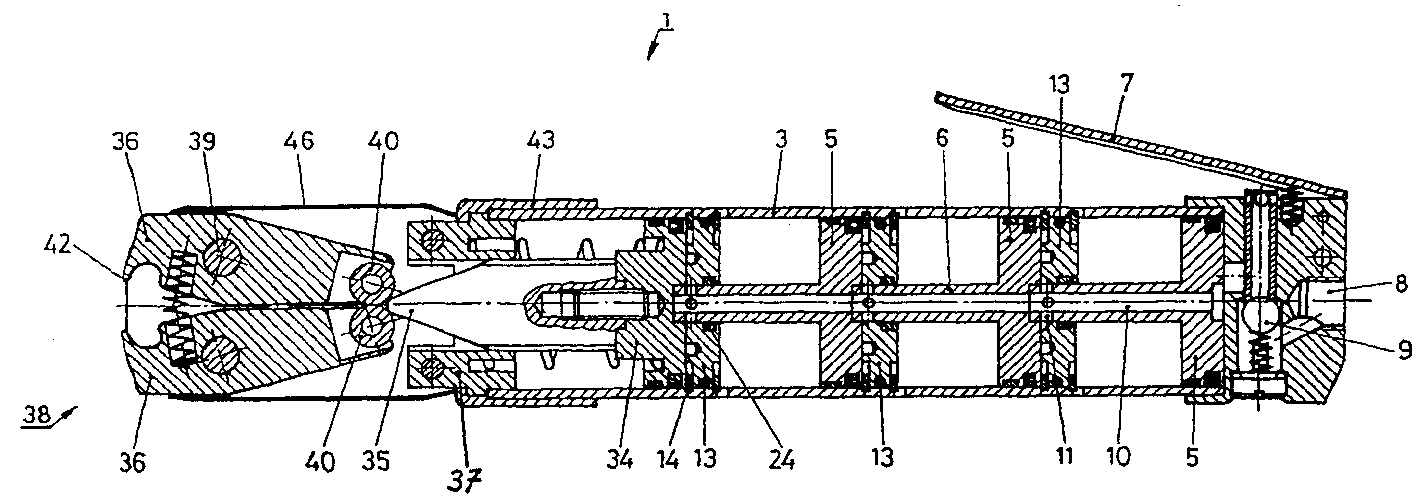

Device for pneumatic operation tool and pneumatic pliers with the device

InactiveCN1264650CReduce static frictionReduce kinetic frictionPliersServomotorsPiston GuideEngineering

The implement, especially pneumatic tongs (1) has a cylinder (3) with one or more pneumatically operated pistons in a row. Each piston rod (6) in the cylinder cover (13) is sealed and guided by means of a seal (24) against the previous piston (5). Components (34,35) cooperate with the piston(s) for operating the implement. The pistons are supported by at least one piston-guide-belt towards the cylinder's inner wall.

Owner:OETIKER SCHWEIZ AG

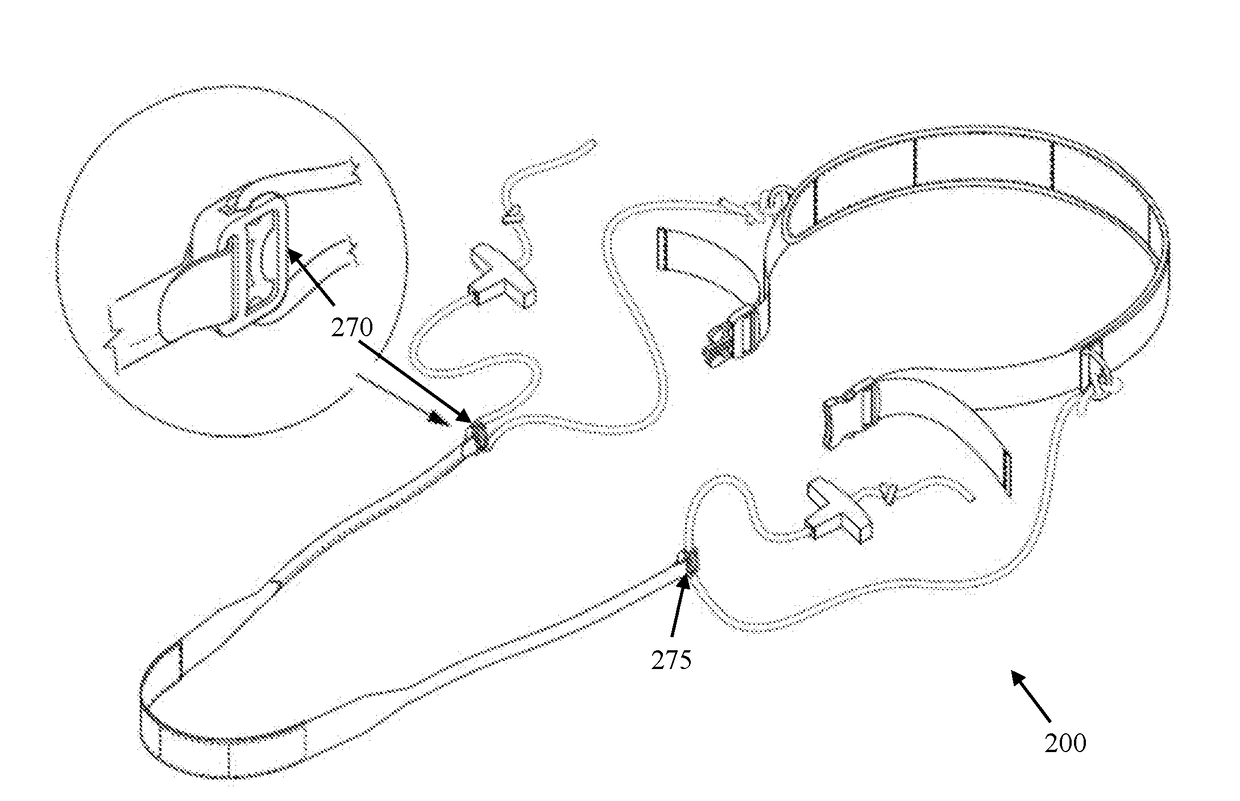

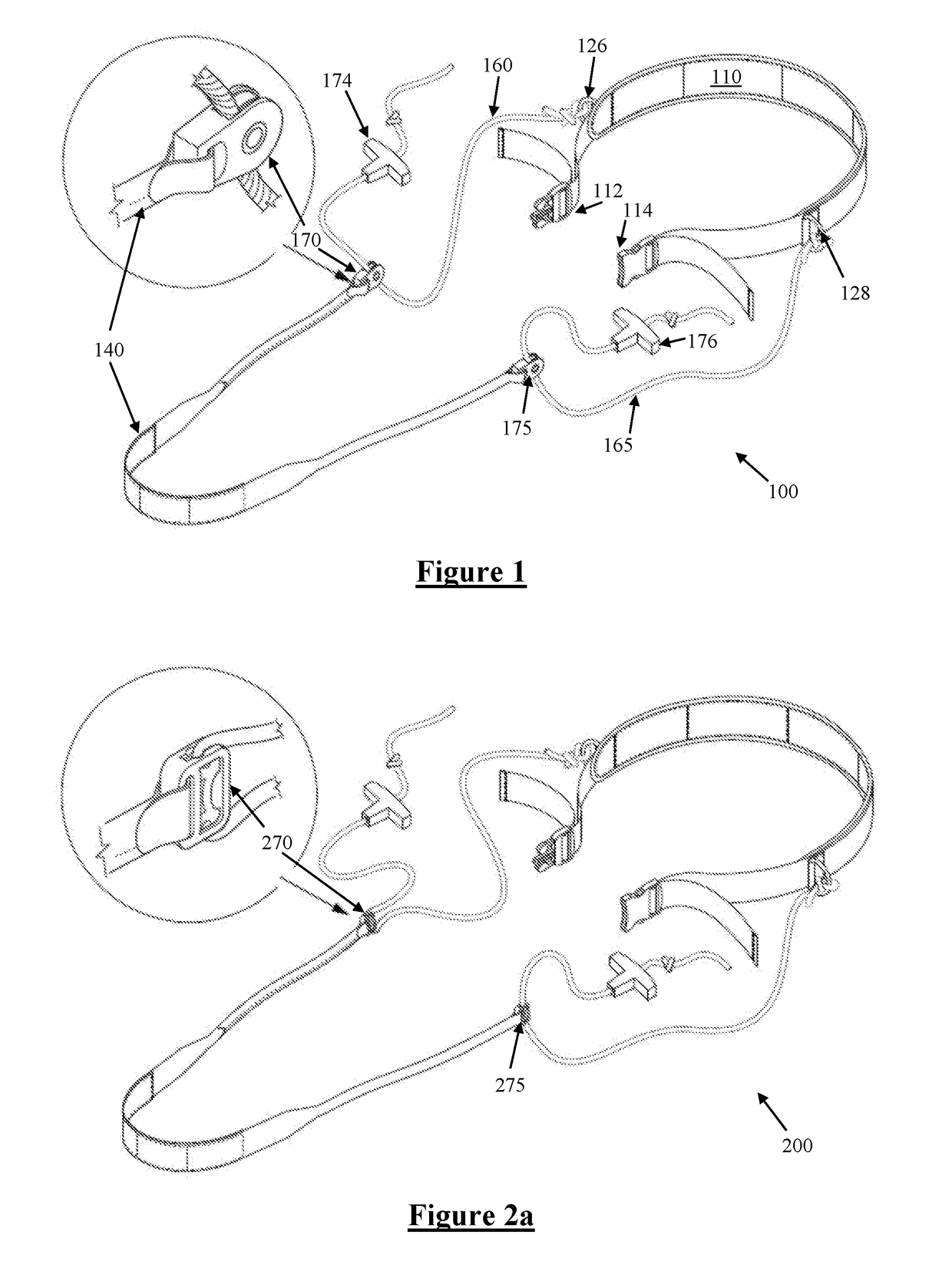

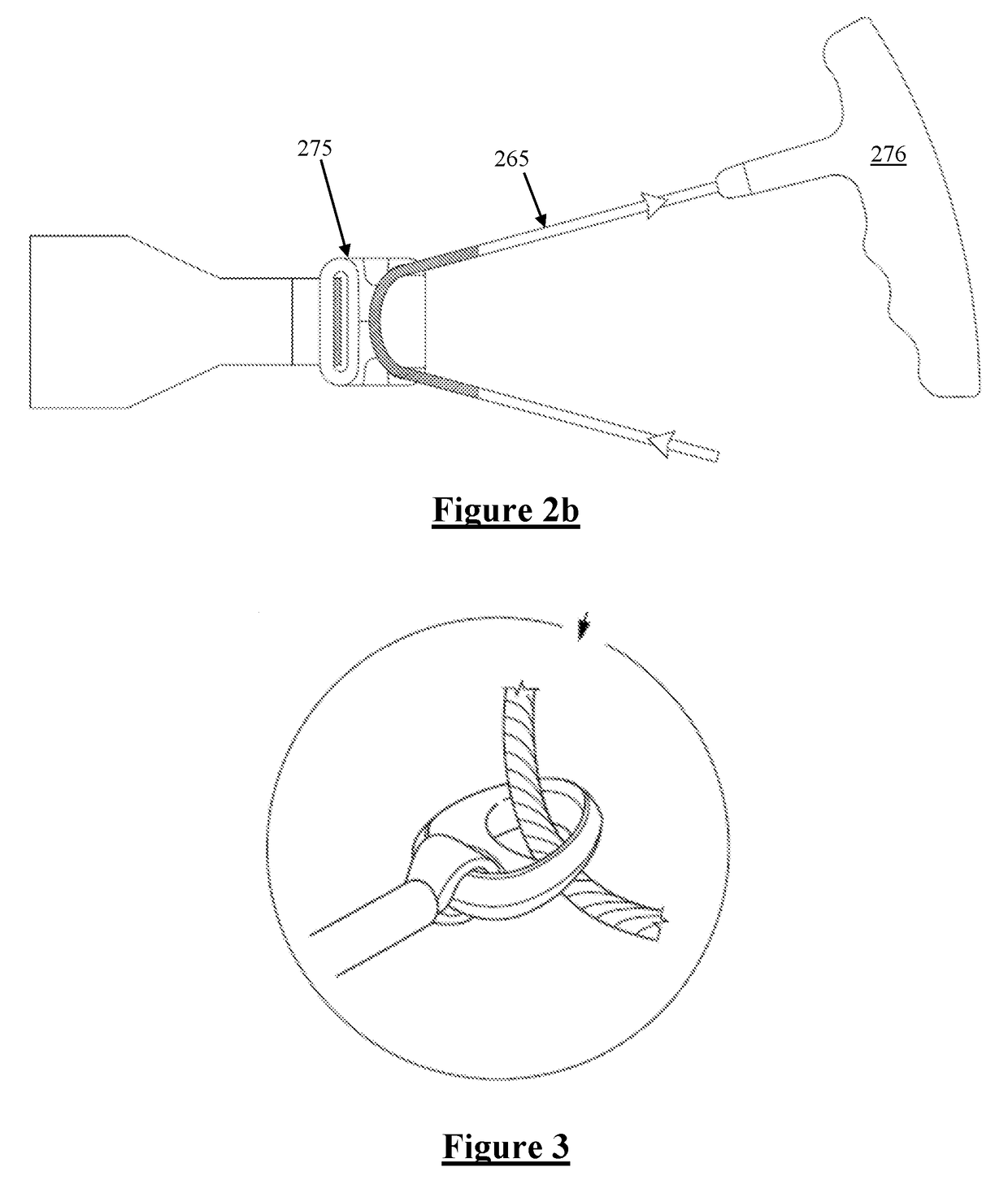

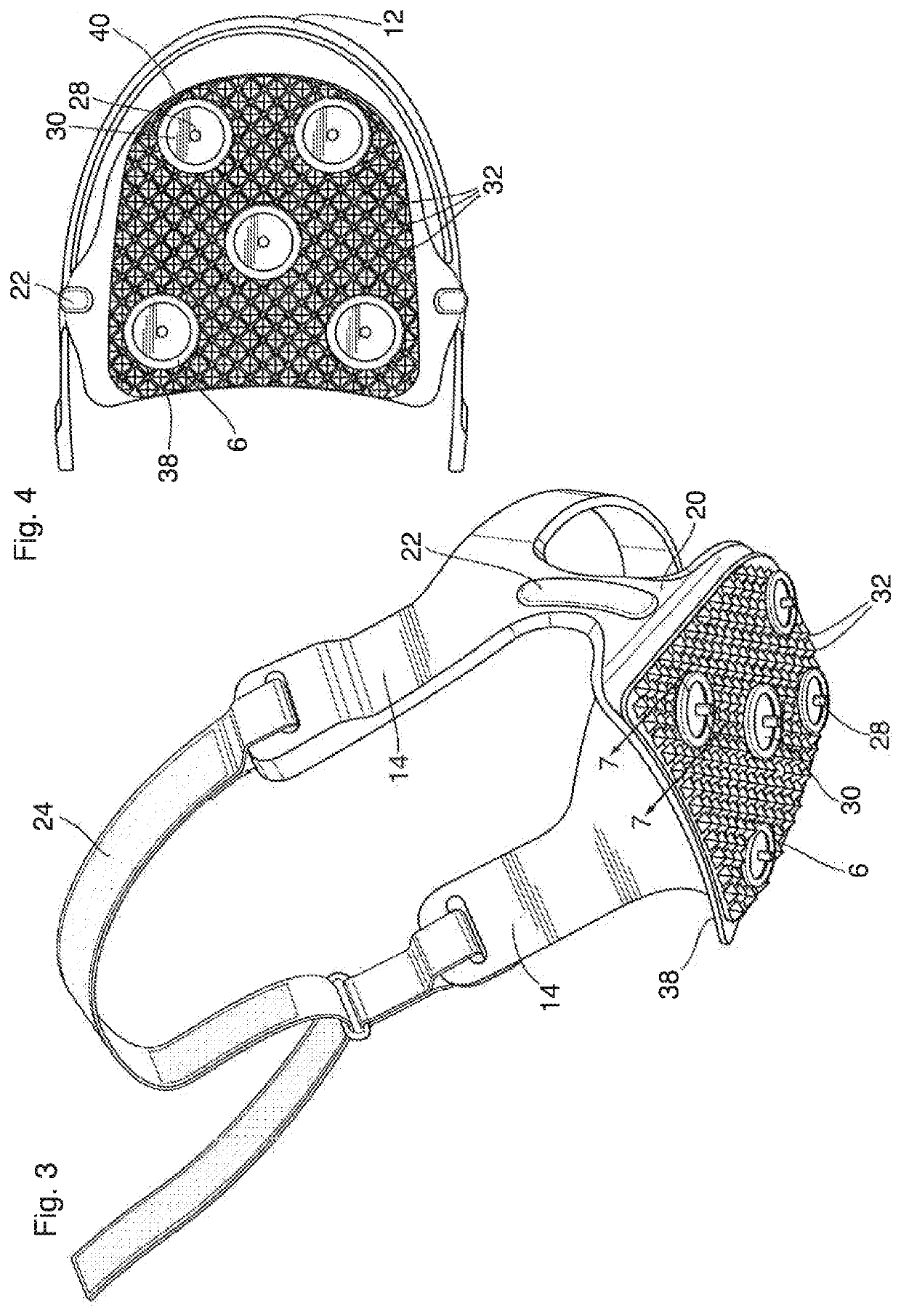

A dual hand controlled device for leg stretching and/or activation

ActiveUS20180296420A1Reduce kinetic frictionMaximising static frictionChiropractic devicesRoller massageEngineeringBiological activation

An independent stretching device comprises a back brace configured to pass across and brace against a user's back. A first connector is secured to a first end of the lower back brace, and is threaded through a first pulley. A second connector is secured to a second end of the lower back brace on an opposite side of the user to the first end of the back brace, the second connector being threaded through a second pulley. A foot stirrup is provided for receiving a foot of the user, and has a first end connected to the first pulley and a second end connected to the second pulley. Tension applied to respective distal ends of the first and second connectors distal from the back brace creates tension which urges the foot stirrup and the back brace toward each other.

Owner:ANDREWS STUART

Electrical component and electronic device

ActiveUS10027048B2Achieve effectEasy to limitCoupling contact membersFixed connectionsElectricityElectrical connection

An electrical component includes a connection portion that is to be in contact with other electrical component and is to establish an electrical connection with the other electrical component. The connection portion includes a plating film that defines a surface of the connection portion. The plating film includes a metal as a main constituent and an aromatic compound that is dispersed in the plating film. The aromatic compound has pi-acceptability and causes ligand field splitting equal to or greater than that of 2,2′-bipyridyl in spectrochemical series. A content of the aromatic compound in the plating film is equal to or greater than 0.1 weight percent, in terms of carbon atoms, with respect to the metal of the plating film.

Owner:DENSO CORP

Yarn wet waxing process

The invention discloses a yarn wet waxing process, wherein a yarn is sequentially subjected to dilution, PH value adjusting, impregnation, and dehydration drying to complete the waxing process. According to the present invention, the excellent and uniform waxing effect can be achieved by using the wet waxing of the liquid wax, the treated yarn has characteristics of low surface kinetic friction value, weaving enhancing, and hairiness reducing; and with the waxing process, the cohesion between the fibers is increased, the strength of the yarn is improved, the yarn is smooth and soft, and is easy to weave, the addition of the softener is not required, yellowing and discoloration cannot occur during the treatment and the drying process, the removal with the refining is easily performed, and the knitted fabric has characteristics of good hand-feeling and good electric resistance.

Owner:RUGAO CHANGJIANG SCI & TECHCAL IND CO LTD

Air conditioner

PendingCN107327949AReduce contact areaFlexible rotationLighting and heating apparatusNoise suppressionEngineeringFriction force

The invention discloses an air conditioner. The air conditioner comprises a shell, wind deflectors and a fixed base. The shell comprises an air outlet. The air outlet is formed in the length direction of the shell. The wind deflectors are arranged in the length direction of the air outlet. The fixed base is located below the wind deflectors, and the wind deflectors are connected with the fixed base in a rotating manner. Supporting ribs are arranged on the portions, corresponding to connection positions of the wind deflectors, on the top of the fixed base. The bottoms of the wind deflectors are connected with the supporting ribs in an abutting manner so that the contact area of the wind deflectors and the fixed base can be reduced. By means of the technical scheme, the friction force borne by the wind deflectors during rotation is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Mid-sole traction device

A mid-sole traction device for a shoe or a boot comprises a traction platform formed of a flexible rubber material. The platform has a first face for contacting a ground surface and a second face for attachment to a mid-sole of the shoe / boot. The first face is spaced from the second face. First and second protrusions are formed on the first face. The first protrusion has first and second ends, each of which defines an opening for receiving a spike. The second protrusion has first and second ends, each of which defines an opening for receiving a spike. The second protrusion is separate and spaced from the first protrusion. A first slot is formed in the platform and is located near a first peripheral edge of the platform for receiving a strap. A second slot is formed in the platform near a second peripheral edge for receiving a strap.

Owner:DENTEC SAFETY SPECIALISTS INC

Method for manufacturing self-lubricating zinc-plastic composite micro bearing

The invention relates to a method for manufacturing a self-lubricating zinc-plastic composite micro bearing, which comprises the following steps: firstly, uniformly mixing 9 to 15 percent of tin, 4 to 6 percent of copper, 2 to 5 percent of lead, 2 to 5 percent of antimony, 0.5 to 0.8 percent of iron, 0.5 to 0.8 percent of nickel and 67 to 82 percent of zinc in percentage by weight to form zinc-based bearing alloy powder; then, mixing 80 to 95 percent of polytetrafluoroethylene and 5 to 20 percent of polyphenyl support material by weight to form solid lubricant; mixing 20 to 50 percent of solid lubricant and 50 to 80 percent of zinc-based bearing alloy powder by weight to form molding powder; and pressing the molding powder, putting a molded piece into a protective gas sintering furnace which uses nitrogen as matrix, and sintering the molded piece at the sintering temperature of between 360 and 410 DEG C for 30 to 60 minutes to form the micro bearing. The method of the invention is simple, economic and practical; and the micro bearing manufactured by the method has the advantages of long service life, good using effect, low cost and small floor area, and is suitable for popularization and use.

Owner:陈政

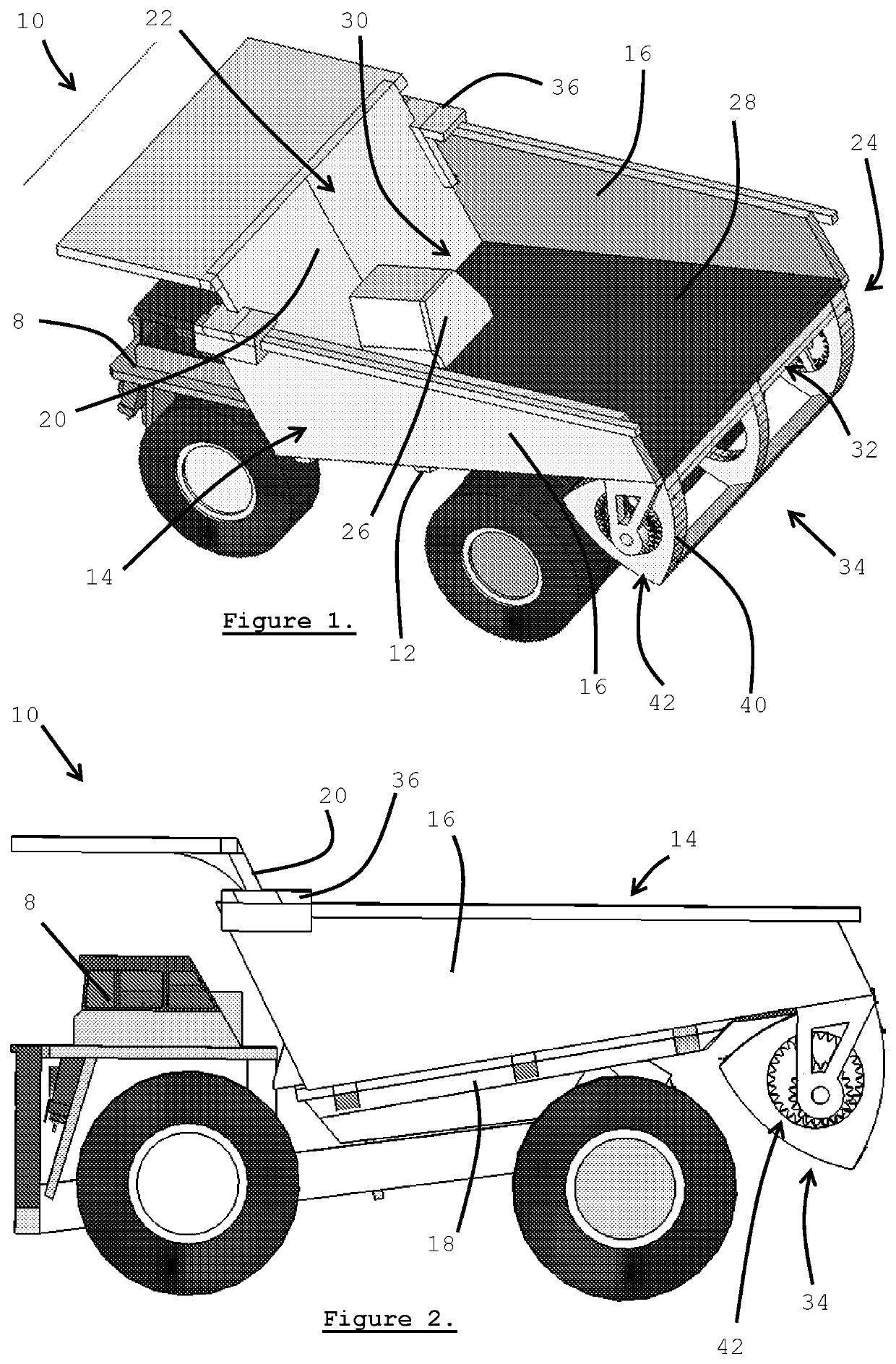

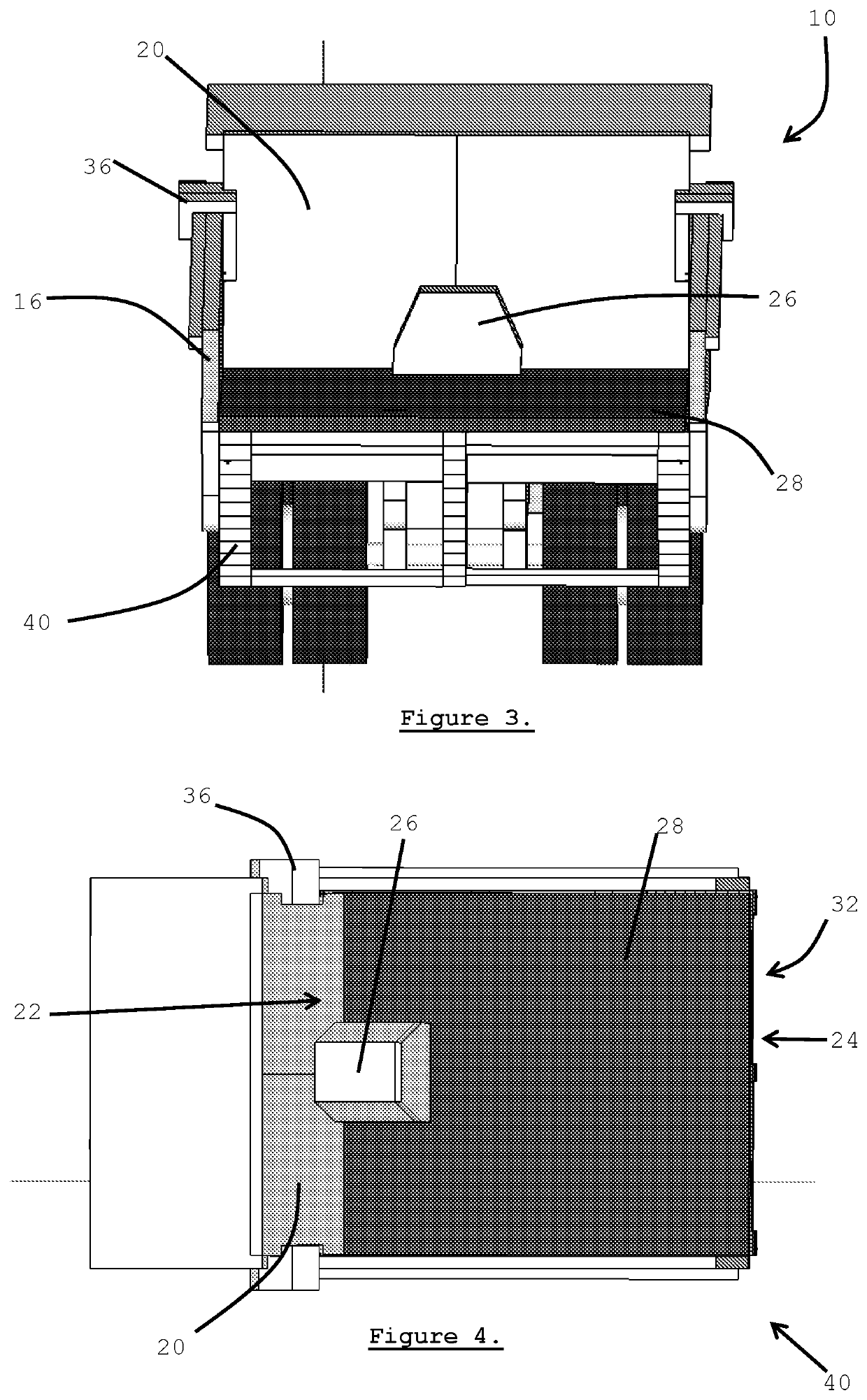

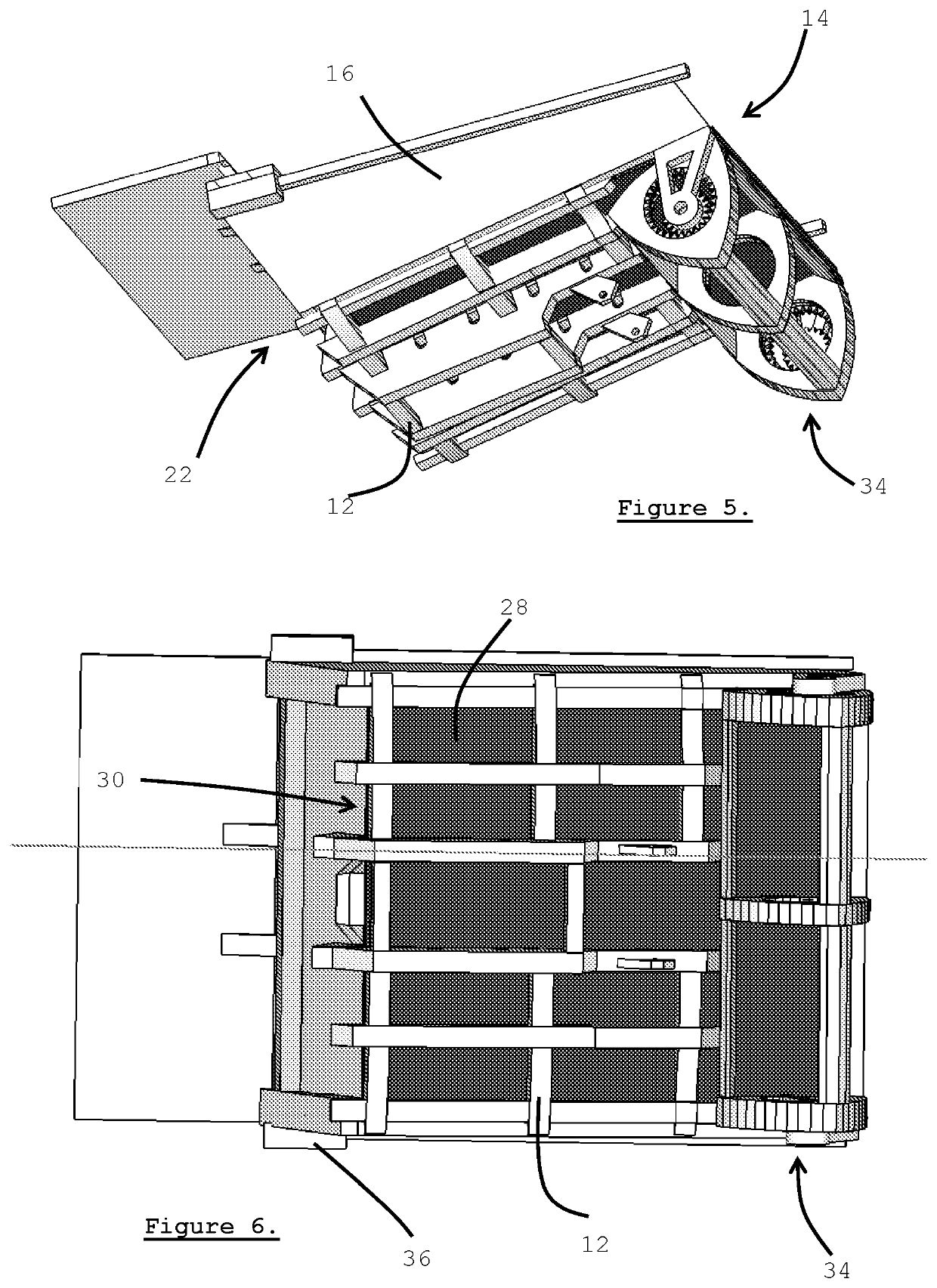

Particulate material haulage arrangement

ActiveUS11001185B2Minimize damageReduce kinetic frictionLarge containersVehicle with pusher plateStructural engineeringParticulate material

A haulage arrangement has a frame configured for operative attachment to a suitable tractor, and defining a tray for operatively receiving particulate material therein. The tray comprises two side walls separated by a loadbearing lower section with a headwall at a head end of the tray and slidably arranged in-between the side walls. Also included is an urger at the head end configured to operatively urge the headwall to slide across the lower section. Arrangement further includes an elastically flexible floor slidably arranged on the lower section and fast at a first end with the headwall, as well as a retractor arranged at an ejection end of the tray and configured to continuously retract a second end of the floor underneath the lower section whilst the headwall is urged. The retractor is further configured to agitate the floor during retraction to counteract adhesion of particulate material ejected from the tray.

Owner:629 032 373 PTY LTD

Glass toughening bent upper roller way structure which is reliable and stable in forming

PendingCN112062453AReduce kinetic frictionQuality improvementGlass reforming apparatusGlass tempering apparatusDrive wheelDrive shaft

The invention discloses a glass toughening bent upper roller way structure which is reliable and stable in forming. An upper forming roller way comprises a driving mechanism, a transmission shaft andan upper roller shaft set; the upper roller shaft set is arranged below an upper air grid set, a driven wheel is arranged at one end of the transmission shaft, the transmission shaft is in transmission connection with the driving mechanism through the driven wheel, and a clutch is arranged at the other end of the transmission shaft. The driving mechanism and the upper roll shaft set transmit powerthrough a clutch of the transmission shaft; the upper roll shaft set comprises a plurality of upper roll shafts; the upper roll shafts are rotationally arranged between two adjacent rows of upper airgrids of the upper air grid group; the two ends of each upper roller shaft are each provided with a roller shaft transmission gear, and the roller shaft transmission gears at the same ends of every two adjacent upper roller shafts are in transmission connection through a transition gear set. According to the glass toughening bent upper roller way structure reliable and stable in forming, dynamicfriction between glass and the upper roller shaft of the upper forming roller way is effectively reduced, the upper roller shaft is prevented from scratching the glass, and the quality of finished glass is improved.

Owner:SOOS (GUANGDONG) GLASS TECH CO LTD

Heel traction device

PendingUS20220031026A1Lower coefficient of dynamic frictionProtect the surfaceFasteningsRubber materialPhysical medicine and rehabilitation

A heel traction device for attachment to a heel of a shoe or a boot comprises a traction platform formed of a flexible rubber material. The traction platform has a first face for contacting a ground surface and a second face for attachment to the heel of the shoe or boot. The traction platform defines a plurality of openings formed therethrough for receiving a traction element in each of said openings. A support band is connected to the traction platform for securing the traction platform to the shoe or a boot. The support band has a rear portion for attachment to a rear portion of the shoe or the boot and two opposing side portions for attachment to side portions of the shoe or the boot. Each of the side portions define a slot formed therethrough for receiving a strap.

Owner:DENTEC SAFETY SPECIALISTS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com