Device for pneumatic operation tool and pneumatic pliers with the device

A tool and piston technology, applied in the field of pneumatically operated devices, can solve the problems of discrete extrusion force, failure to maintain extrusion force, loss of extrusion force, etc., and achieve the effect of low dynamic friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

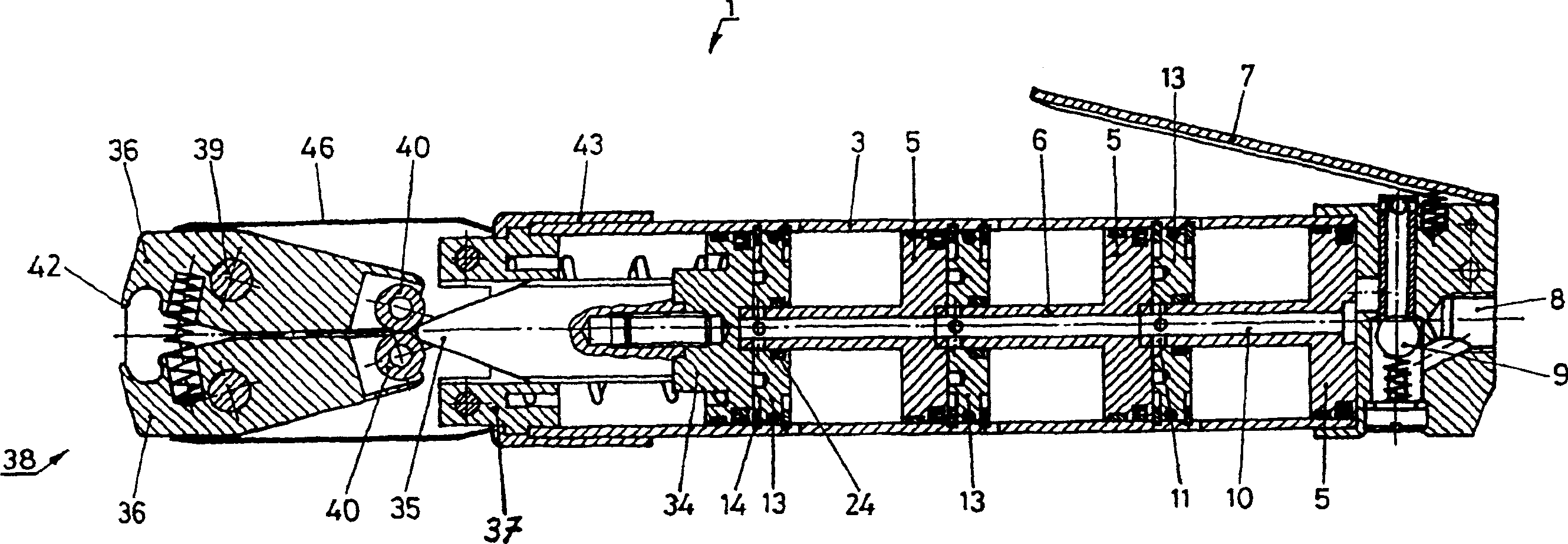

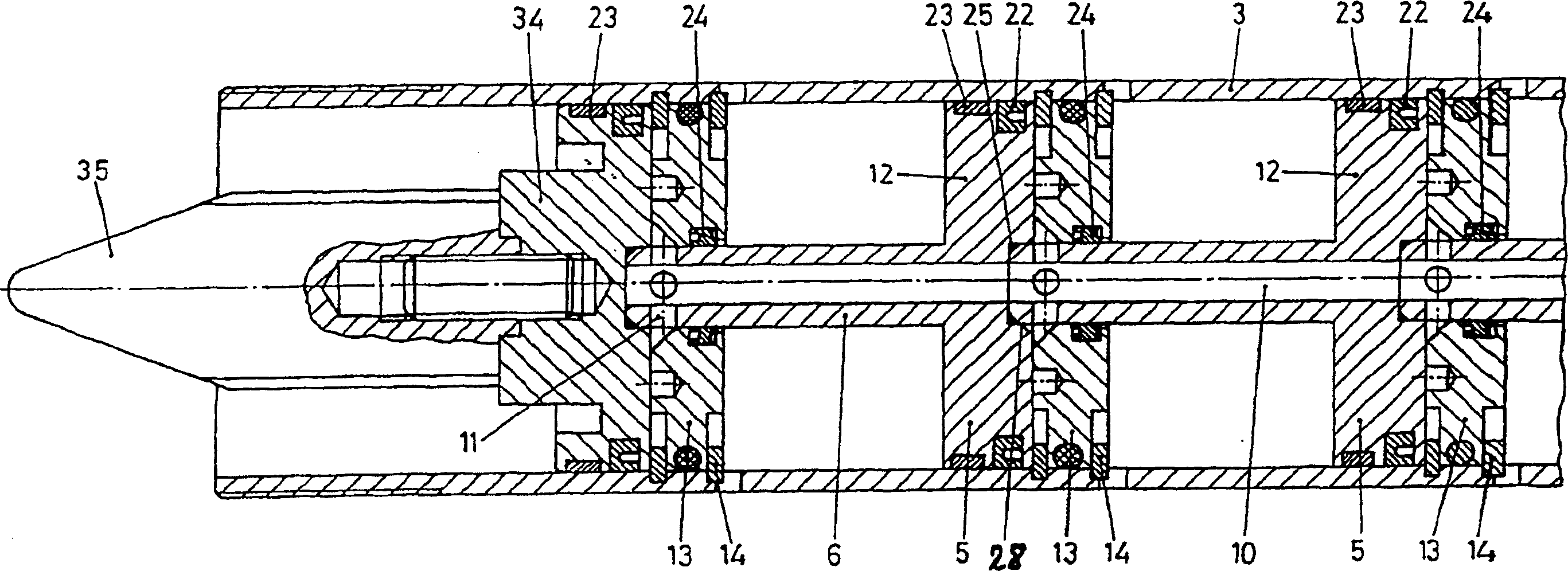

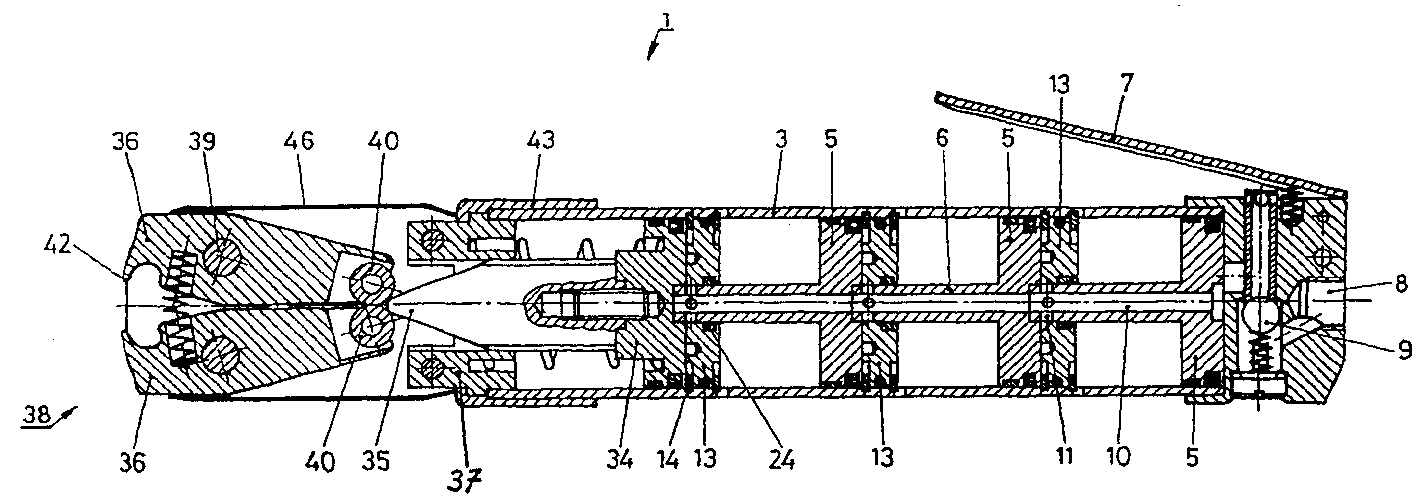

[0021] figure 1 A longitudinal sectional view is shown of a pneumatically actuatable and pressure-driven pliers 1 for mounting pipe clamps, hose clamps, retaining rings and the like. A plurality of pistons 5 arranged one behind the other in a row or series are arranged in a cylinder 3 . The advantage of such a series arrangement of pistons is that the force is increased by making it possible to generate displacement forces that are much greater than with a single piston. The reason is to increase the piston area.

[0022] A connection 8 is provided at the rear end of the manually actuatable pneumatic clamp, which connects the clamp to a pressure medium, for example compressed air, wherein the pressure medium can be supplied by means of a valve handle for actuating a valve 9 7 to open or ventilate. The individual pistons 5 have a through-bore 10 through the piston rod 6 for the passage of pressure medium. At the front end of the piston rod 6 there is provided a radially out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com