Excitation fluctuation precompressed multi-station compression moulding machine

A multi-station, molding machine technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of single size, shape, short molding action time, difficult dynamic positioning, etc. The effect of reducing casting and machining costs, consistency and reliability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings in the form of embodiments.

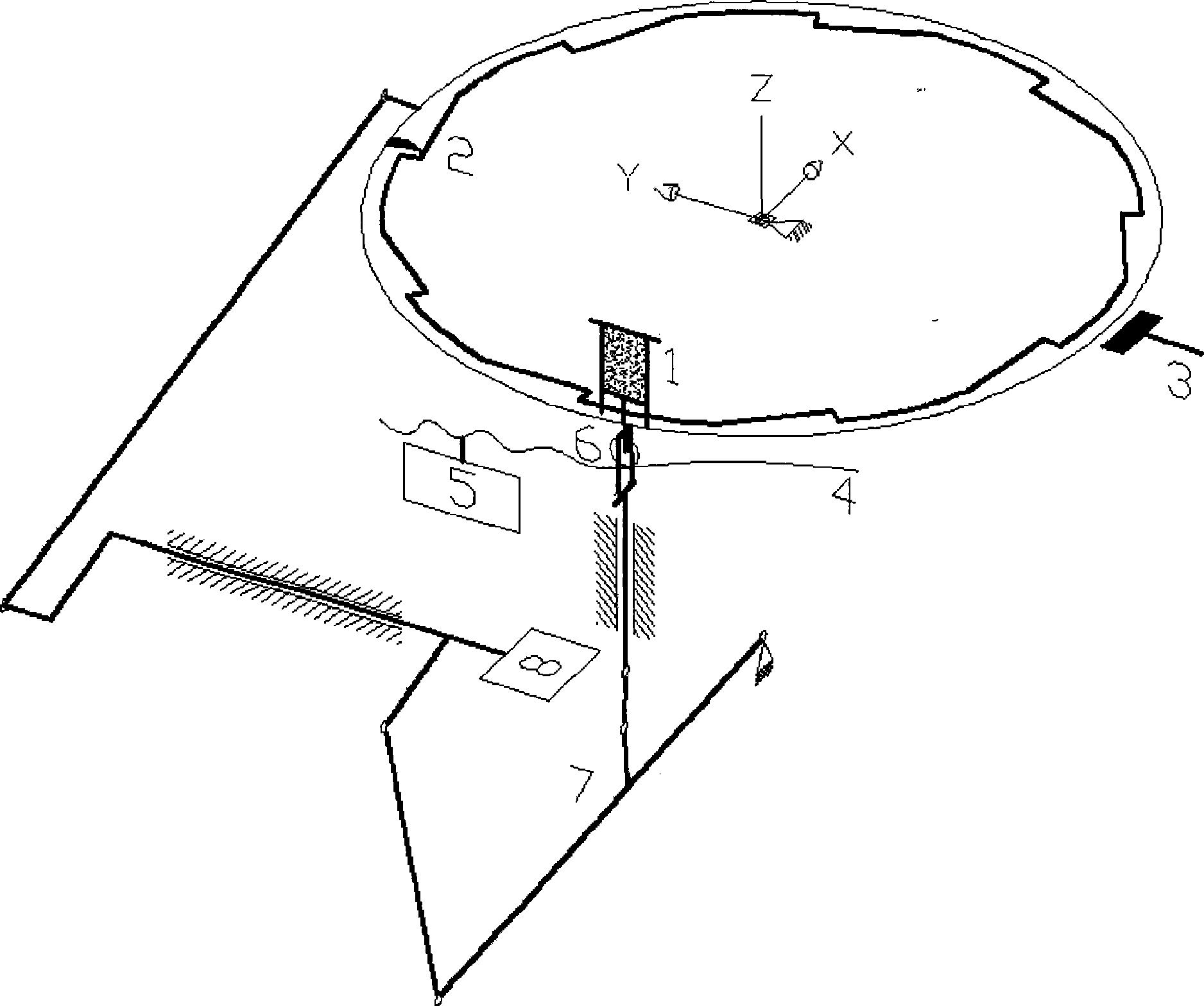

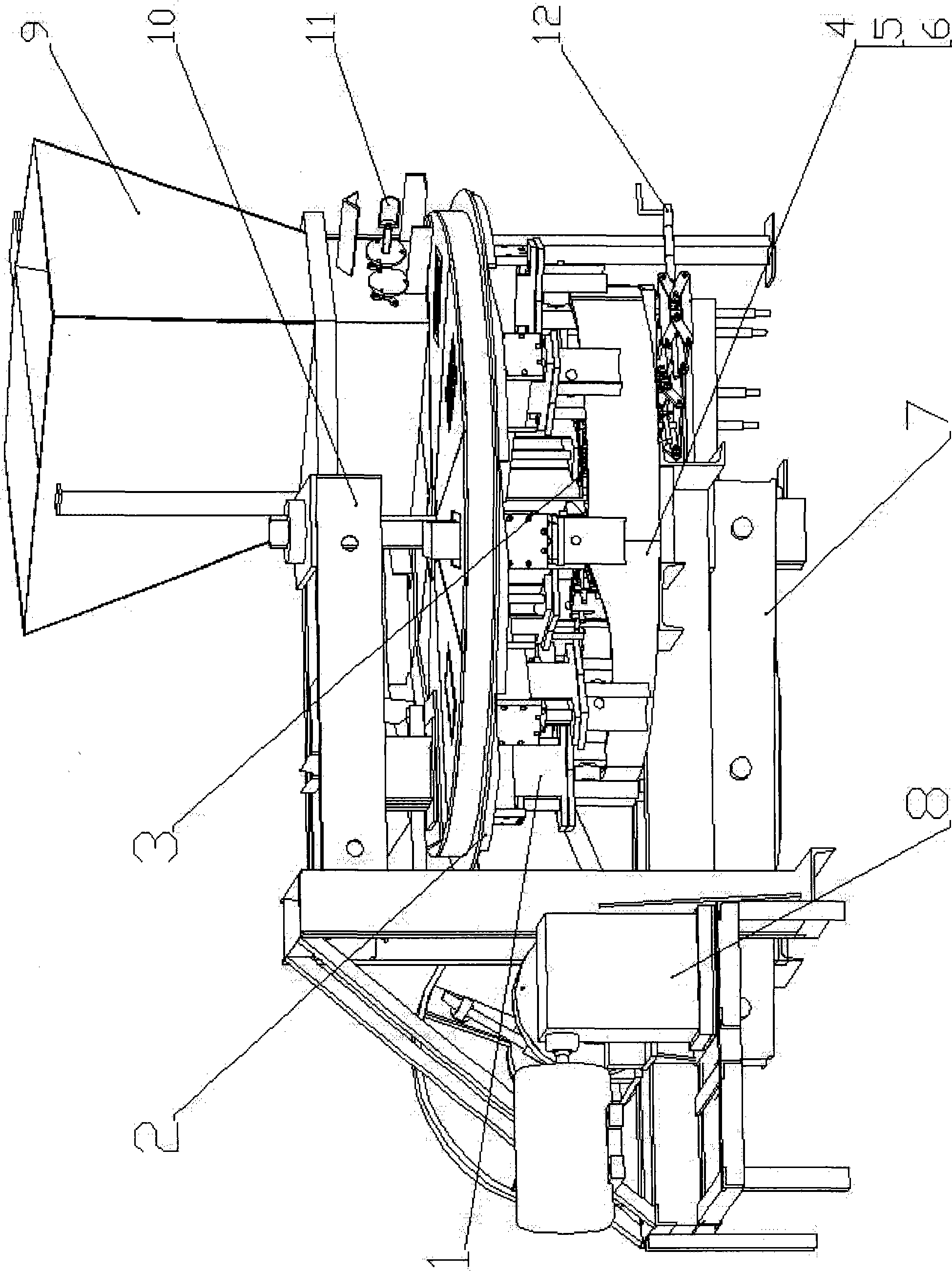

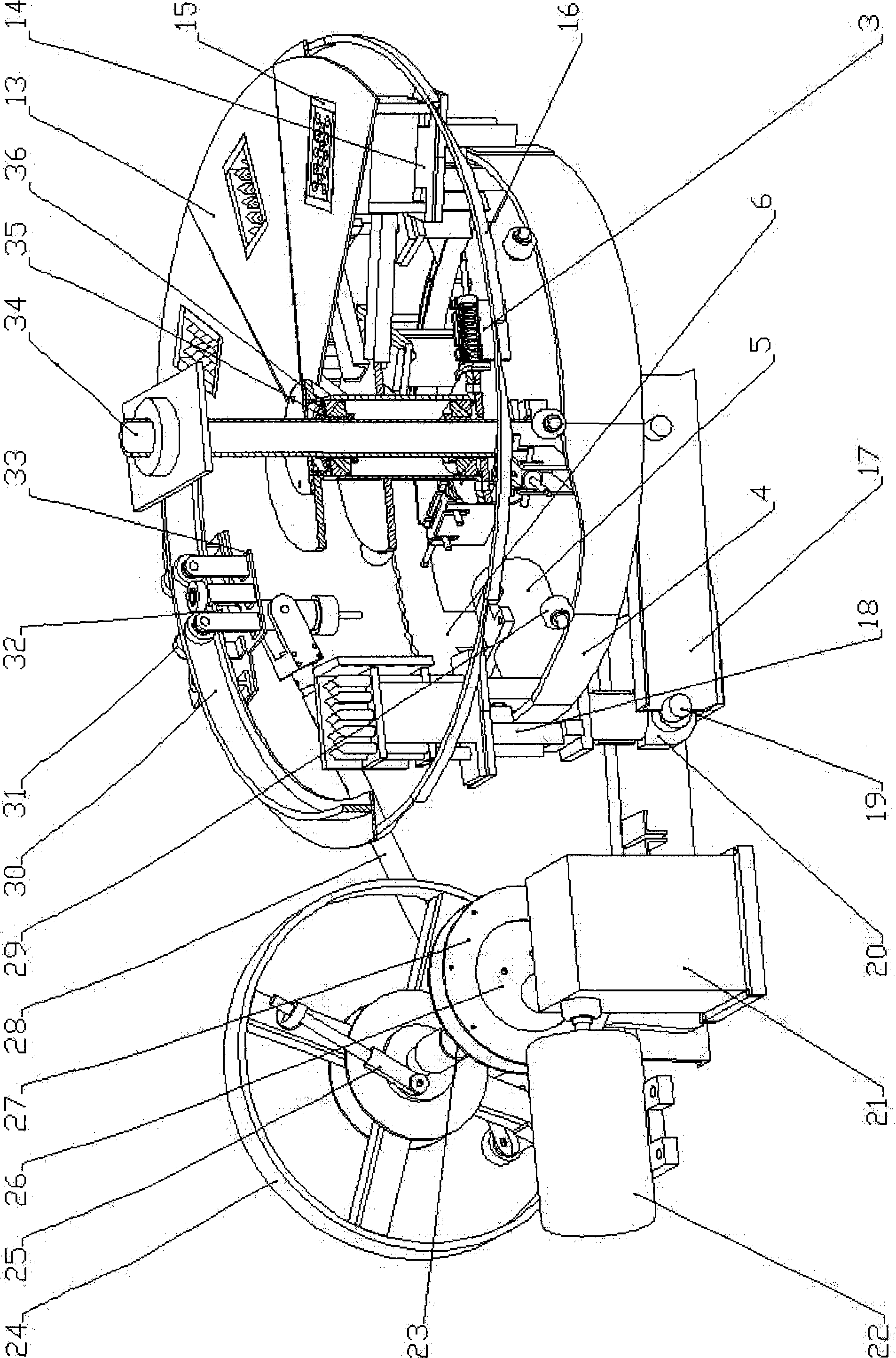

[0064] The multi-station molding machine with vibration and fluctuation pre-compression of the present invention consists of a molding unit 1, an intermittent mechanism 2, a damping device 3, a slideway 4, a forced vibration source 5, a pre-compression device 6, a booster device 7, a transmission system 8, and a hopper 9. Composed of frame 10, forced agitator 11, charging adjustment device 12, etc.; each molding unit is evenly distributed on the same circumference and assembled into a rotating body 13 to rotate around the central axis 34, the upper end of the central axis 34 is fixed to the beam 39, and the lower end is connected to the Base 37 is fixed, and the other end of crossbeam 39 is fixed with column 38; 32 and the hole of built-in spring on the pulley 33 are slidably matched, and one end of the push-pull rod 28 is hinged to the tackl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com