Wire paying-off machine

A pay-off machine and frame technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., and can solve the problems of large wear and tear on the outer skin of wires or cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

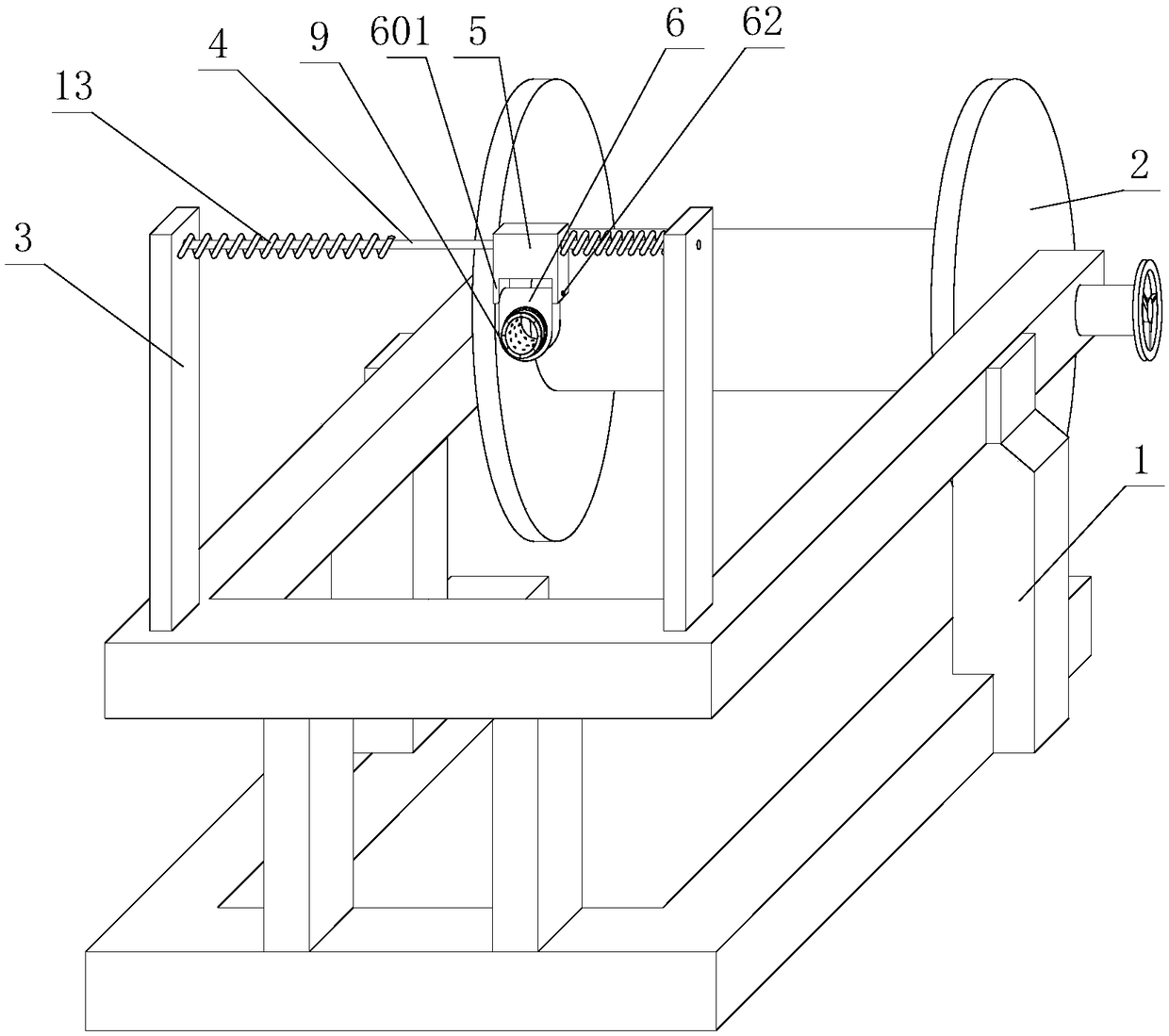

[0022] like Figure 1-3 A pay-off machine shown is a pay-off machine, including a frame 1, a winding shaft assembly 2, a support rod 3, a slide rod 4, a slide block 5, a mounting block 6 and a wire barrel 9;

[0023] The bobbin assembly 2 and the support bar 3 are arranged on the frame 1, the slide bar 4 is fixedly mounted on the support bar 3, the slide block 5 is slidably connected with the slide bar 4, the mounting block 6 is installed on the slide block 5, and the mounting block 6 There is a connecting through hole, the axis of the connecting through hole is perpendicular to the plane where the support rod 3 and the sliding rod 4 are located, and the wire barrel 9 is arranged in the through hole;

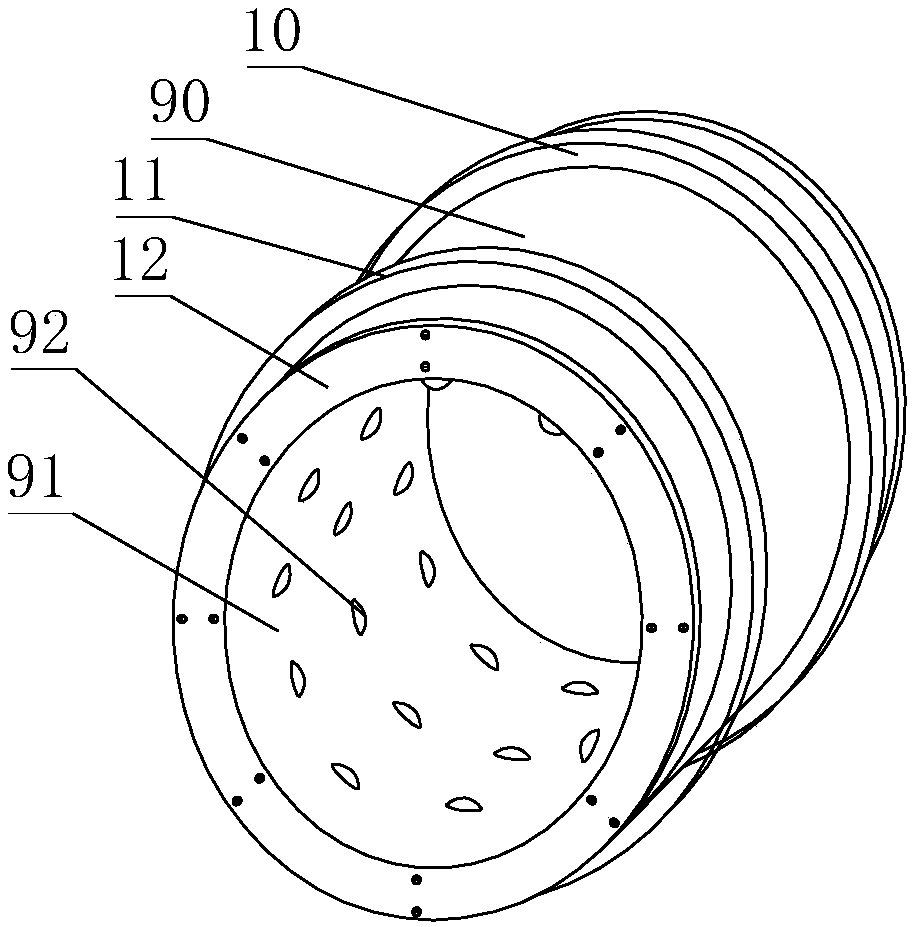

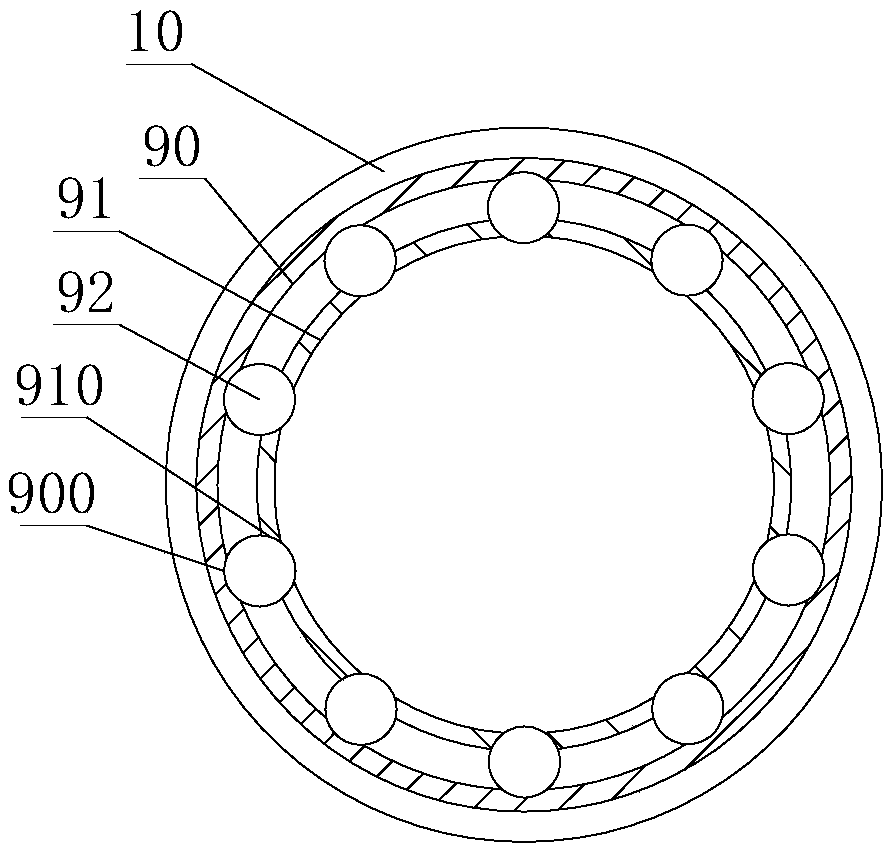

[0024] Wire passing barrel 9 comprises outer layer barrel 90, inner layer barrel 91, roller 92 and cover ring 93, inner layer barrel 90 is sleeved in outer layer barrel 90, roller 92 is arranged on outer layer barrel 90 and inner layer Between the cylinders 91, the roller 92 pr...

Embodiment 2

[0033] like Figure 4-5 As shown, the difference between the present embodiment and the first embodiment is that: preferably, an upper fixing frame 60 is provided between the slider 5 and the mounting block 6, and the upper fixing frame 60 is rotatably connected with the mounting block 6, and the slider 5 and the mounting block 6 are rotatably connected. An elastic bar 14 is arranged between the upper fixed frame 60, and the elastic bar 14 is made of rubber. Relative to the sliding block 5 swinging left and right in the vertical direction, the sliding block 5 is provided with two limit blocks 15 along the swinging direction of the elastic rod 14 . When the wire or cable is pressed against the wire barrel 9, a force is applied to the elastic rod 14 through the mounting block 6 and the upper fixing frame 60, and the elastic rod 14 is deformed to a certain extent, and the elastic rod 14 rotates relative to the slide block 5. After the rod 14 collides with the limit block 15, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com