Flow path switching valve

A flow path switching and spool technology, applied to multi-way valves, valve devices, valve details, etc., can solve problems such as valve leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

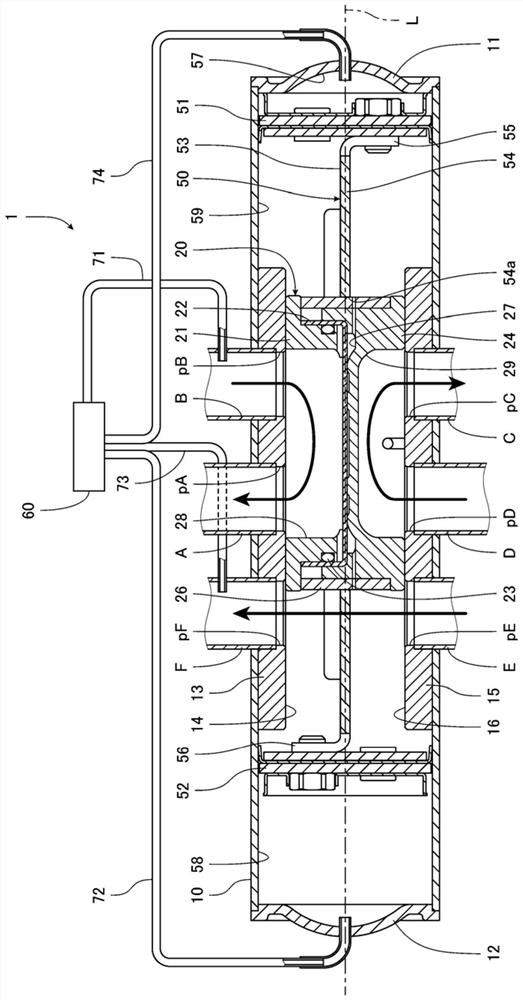

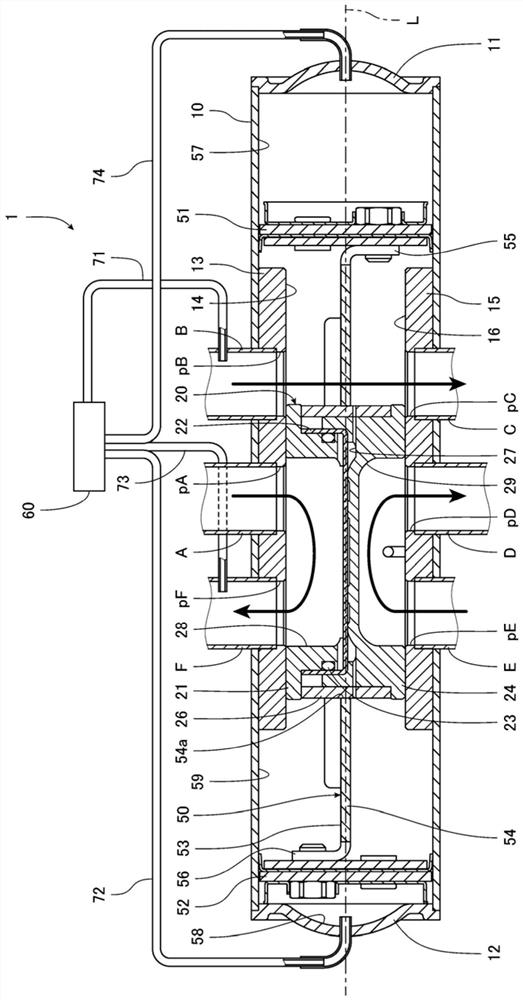

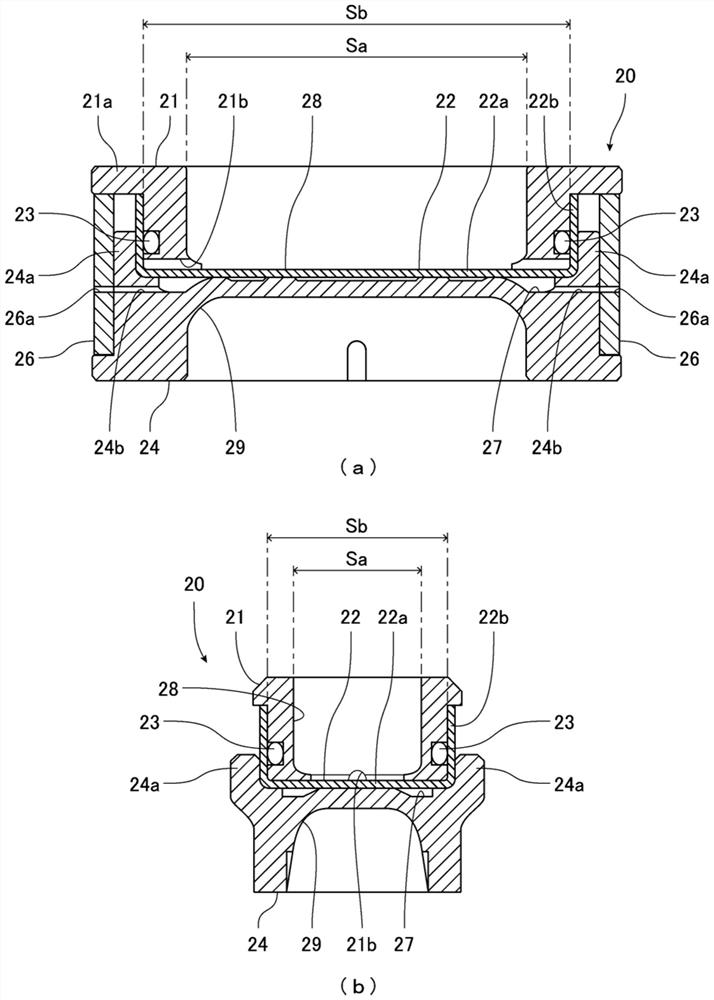

[0030] Below, refer to Figure 1 ~ Figure 4 , the channel switching valve according to one embodiment of the present invention will be described.

[0031] The flow path switching valve of this embodiment is a six-way switching valve used to switch the flow direction of refrigerant as a fluid in response to switching between cooling and heating operations in heat pump cooling and heating systems such as indoor air conditioners and vehicle air conditioners.

[0032] figure 1 , figure 2 It is a cross-sectional view of a channel switching valve according to an embodiment of the present invention. figure 1 Indicates that the spool is at the first stop position (stop position during cooling operation). figure 2 Indicates the state where the spool is at the second stop position (stop position during heating operation). exist figure 1 , figure 2 In , bold arrows schematically represent examples of fluid flow. image 3 is description figure 1 Diagram of the spool that th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap