A camera control system and method based on piezoelectric ceramics

A piezoelectric ceramic and control system technology, which is applied in the parts of TV systems, parts of color TVs, TVs, etc., can solve the problems of unclear shooting pictures, asynchronous shooting and focusing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

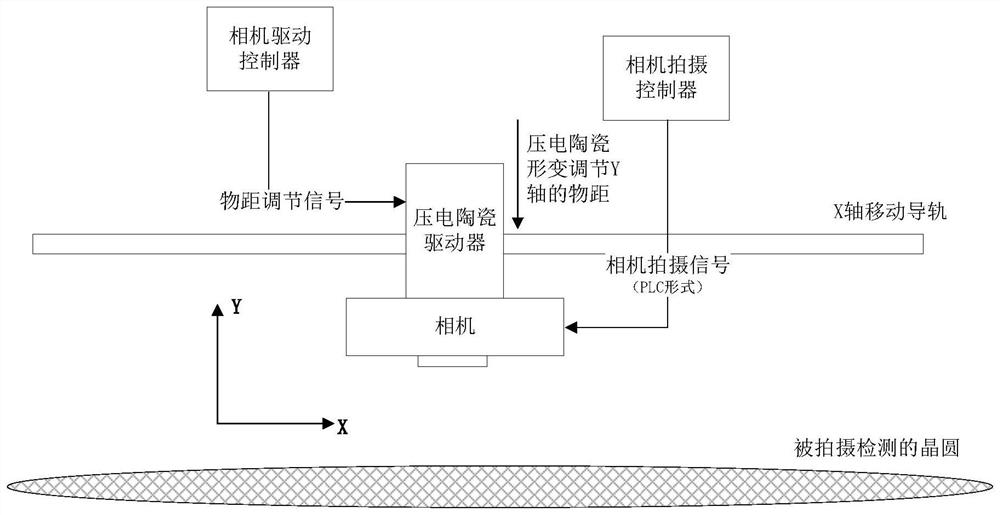

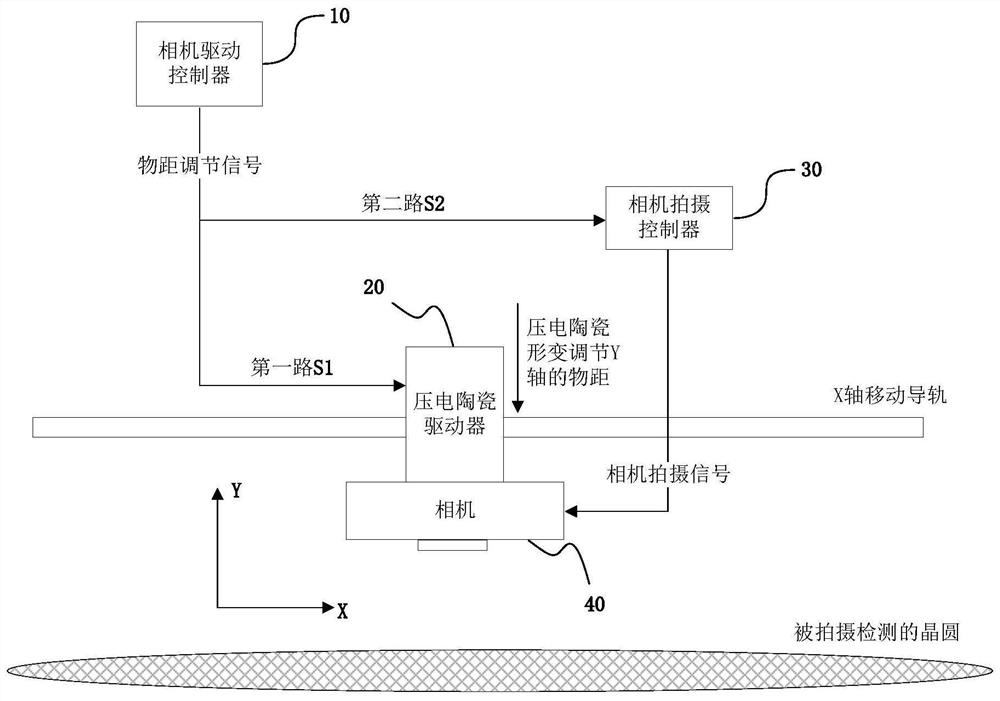

Method used

Image

Examples

Embodiment 1

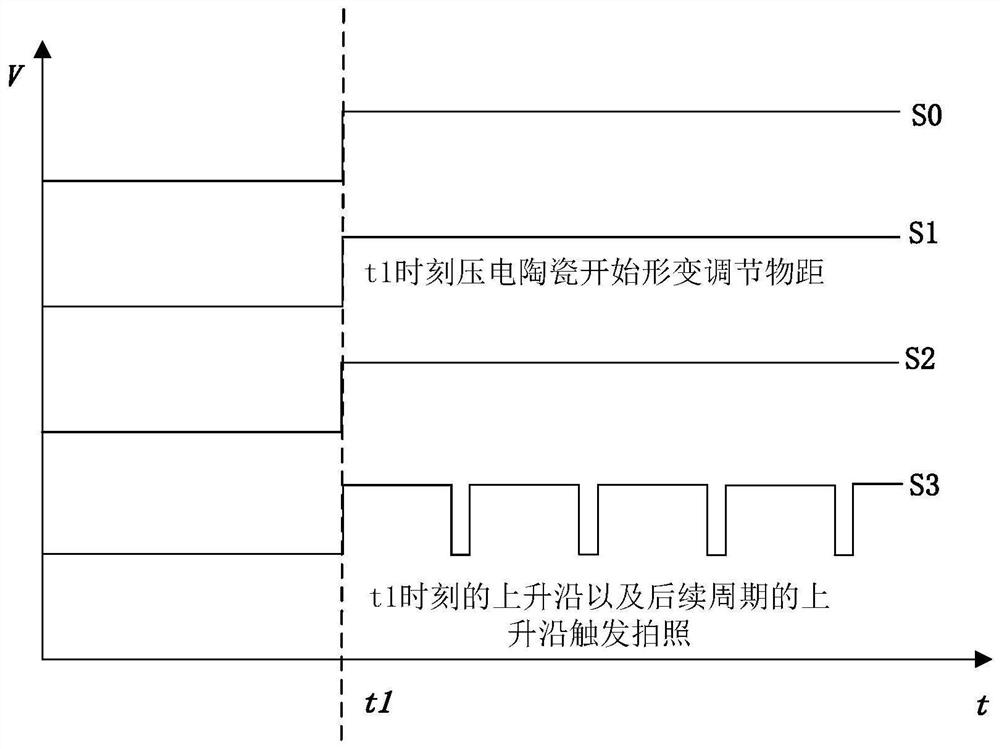

[0052] In this embodiment, the camera shooting controller 30 is configured to generate the camera shooting signal S3 when the rising edge of the second channel signal S2 is detected.

[0053] That is to say, the second signal S2 can be used as a switch signal or a trigger signal of the camera shooting controller 30 to transmit the camera shooting signal S3 to the camera. refer to image 3 As shown in the signal sequence, at time t1, the camera drive controller 10 starts to control focusing, and the object distance adjustment signal S0 generates a rising edge. Correspondingly, at time t1, the first signal S1 and the second signal S2 also rise. edge, the camera shooting controller 30 detects the rising edge of the second signal S2, determines that the switch signal transmitting the camera shooting signal S3 to the camera is in a trigger state, and starts to generate the camera shooting signal S3 and transmit it to the camera.

[0054] Further, since the piezoelectric ceramic dr...

Embodiment 2

[0057] In this embodiment, the camera shooting controller 30 includes an encoder and a modulator (or a synthesizer), the encoder is used to generate the original control signal S4, and the modulator is used to modulate the original control signal S4 and the second signal S2 into a camera Capture signal S3.

[0058] That is to say, in this embodiment, the camera shooting controller 30 continuously transmits the camera shooting signal S3 to the camera, the encoder continuously generates the original control signal S4, and the modulator modulates the original control signal S4 to the second signal S2 On the other hand, the continuous camera shooting signal S3 is generated, and since the second signal S2 is only high after the rising edge, the modulated camera shooting signal S3 is only after the rising edge of the second signal S2. A rising edge occurs, allowing the camera to start shooting after the object distance has been adjusted.

[0059] Further, the modulator can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com