Rotary drying equipment for painted automobile parts

A technology for drying equipment and spare parts, which is applied in spray booths, spray devices, pre-treated surfaces, etc., can solve problems such as affecting drying quality, uneven drying of parts, and odors that are not easy to dissipate, so as to improve drying performance. Drying effect, improve working environment, increase drying range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

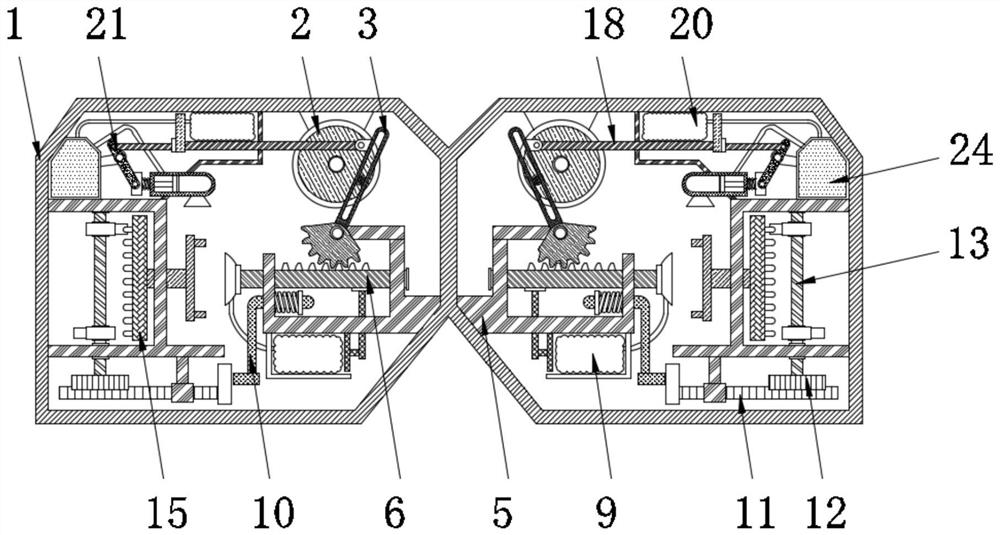

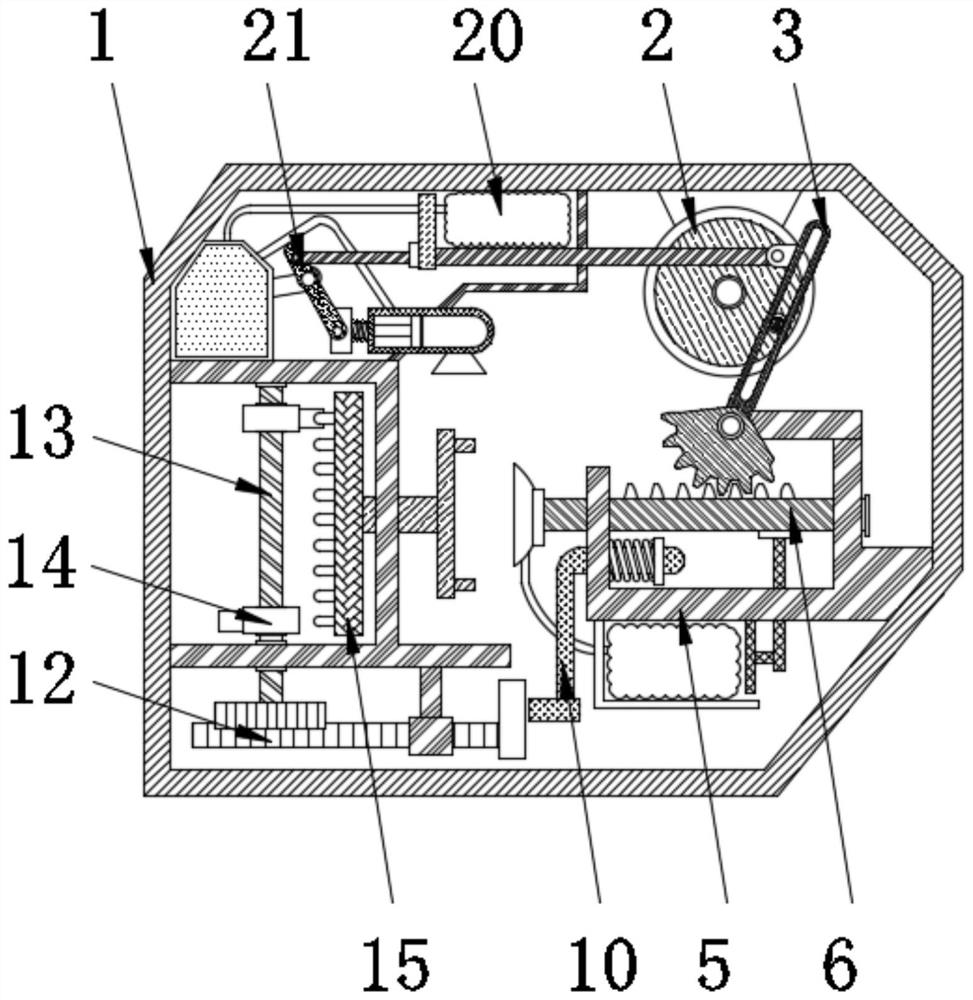

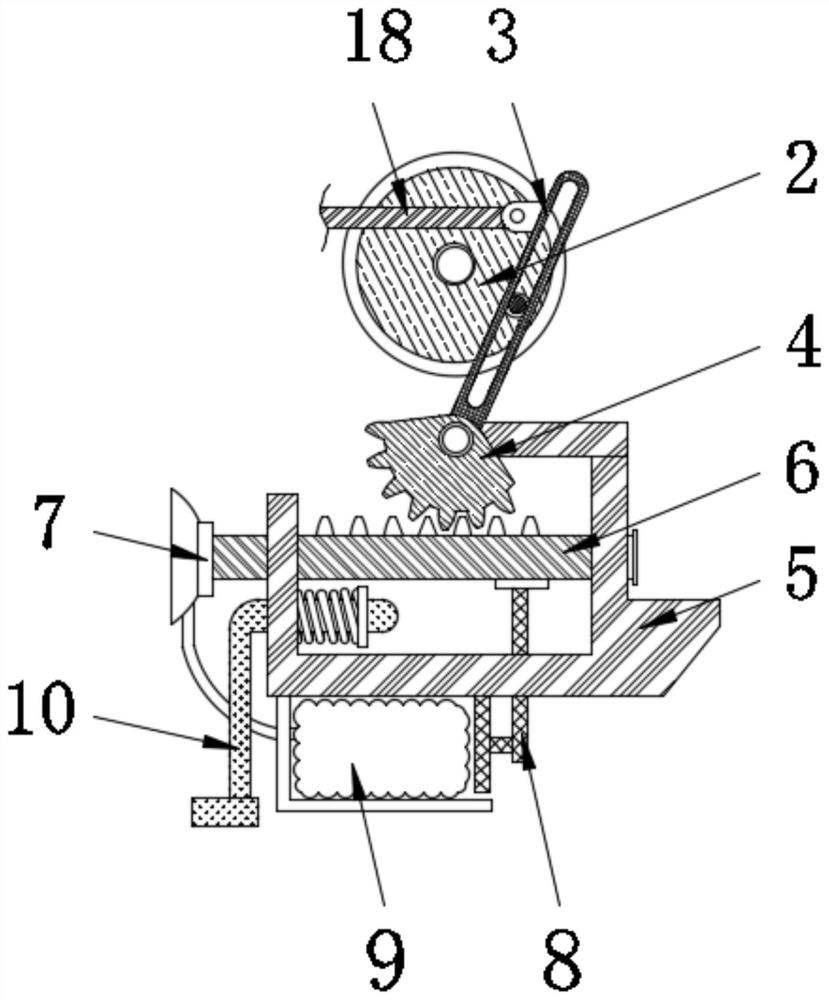

[0022] The invention provides a rotary drying equipment for auto parts after painting, as attached figure 1 to attach Figure 5 Shown: including the processing chamber 1, the internal rotation of the processing chamber 1 is installed with a disc 2, the disc 2 is fixedly connected with the drive shaft, the front surface of the disc 2 is slidingly installed with an adjustment frame 3, and the bottom end of the adjustment frame 3 A half gear 4 is fixedly installed, and the half gear 4 is rotatably installed on the front surface of the fixed seat 5, and the bottom end of the half gear 4 is engaged with a movable rod 6, and the movable rod 6 is slidably installed in the inside of the fixed seat 5, and the disc 2 and the adjustment The joints of the frame 3 are respectively provided with corresponding clamping columns and sliding holes, the upper surface of the movable rod 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com