Foamed plastic saw

A technology of foam plastic and foam, which is applied in the field of plastic saw design, can solve the problems of multi-function, multi-structure effective ventilation and fully automatic control, etc., and achieve the effect of improving safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

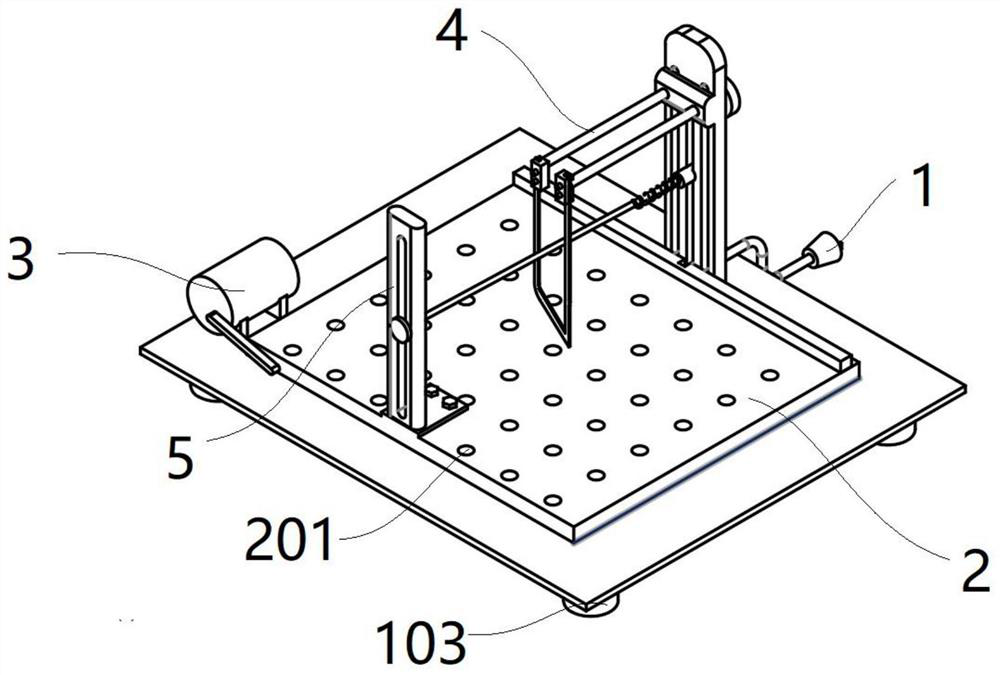

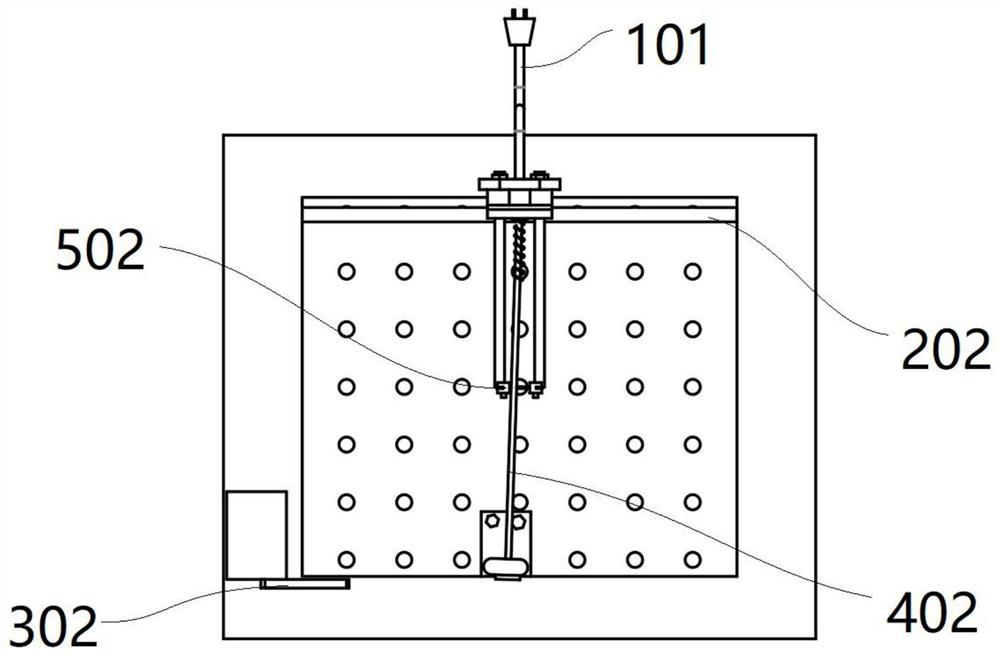

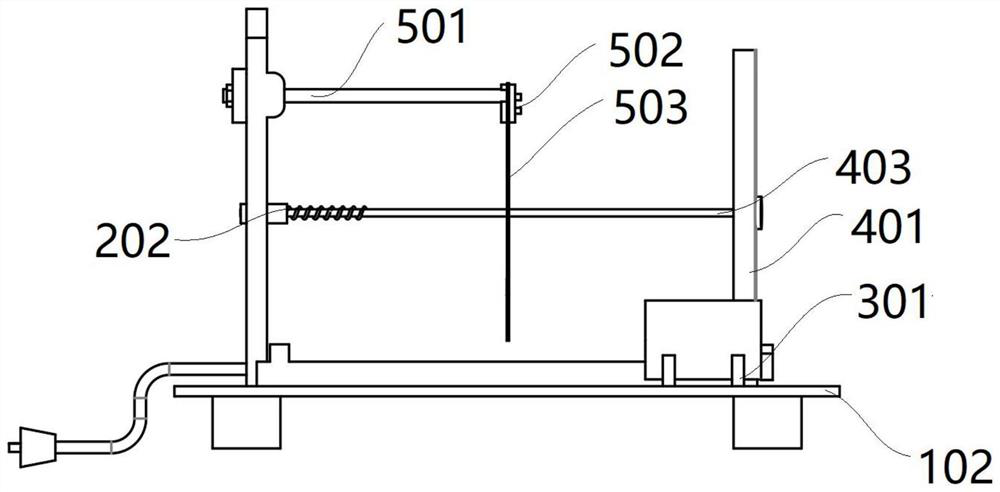

[0028] see Figure 1-2 As shown, the present invention is a foam saw, including a foam saw frame 1, a foam cutting platform 2, an air pump 3, a transverse cutting device 4 and a longitudinal cutting device 5, the foam saw frame 1 includes a support plate 102, and the air pump 3 includes an air pump installation Frame 301, one surface of support plate 102 is welded with one surface of air pump mounting frame 301, the transverse cutting device 4 includes a heating wire support 401, the other surface of support plate 102 is provided with a defined groove, and one surface of the heating wire support 401 is connected with the defined groove. , the longitudinal cutting device 5 includes an electric heating blade support 502 , the electric heating blade support 502 is installed on the other surface of the support plate 102 , and one surface of the foam cutting platform 2 is connected to one surface of the foam saw frame 1 .

[0029] Further, the foam saw frame 1 also includes a main ...

Embodiment 2

[0035] Please refer to figure 1 As shown in -4, the present invention is a kind of foam plastics saw, and its working principle is: when working, the total power line 101 in the foam saw frame 1 and the support plate 102 cooperate with the device, and the anti-skid legs 103 carry out anti-slip, foam The air flotation device 201 and the cutting guide rule 202 in the cutting platform 2 work together, the air duct 302 in the air pump 3 and the inside of the device are ventilated, and the electric heating wire 402 in the horizontal cutting device 4 is used for electric heating, and the electric heating blade of the longitudinal cutting device 5 503 cutting the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com