Steel bar supporting structure for prefabricated pier

A prefabricated assembly and support structure technology, applied in the direction of structural elements, bridges, bridge parts, etc., can solve the problems of different diameters of support structures, difficult to replace steel bars of different diameters, etc., and achieve good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

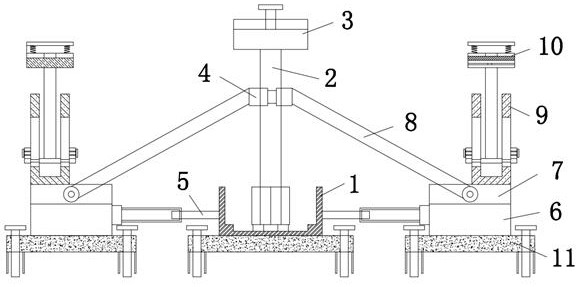

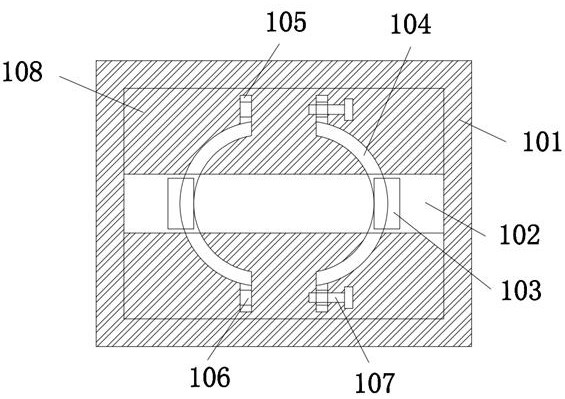

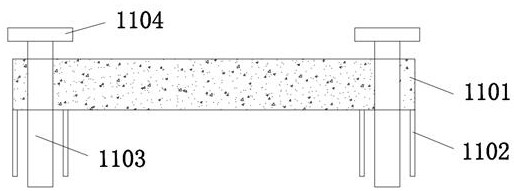

[0038] see Figure 1-Figure 2 , a prefabricated assembled bridge pier steel bar support structure, including a support mechanism 1, a support rod 2 is placed inside the support mechanism 1, and a fixing mechanism 3 is fixedly connected to the top of the support rod 2, and the support rod 2 The outer surface is slidably connected with a moving mechanism 4, and the supporting mechanism 1 includes a support seat 101, a support groove 108 is opened on the top of the support seat 101, and a first sliding groove 102 is opened transversely at the bottom of the support groove 108. The inside of the first chute 102 is slidably connected with two groups of first sliders 103, and the tops of the first sliders 103 of the two groups are all symmetrically fixedly connected with splints 104, and the front and back sides of the splints 104 are fixedly connected with splints. block 105, the right side of the connecting block 105 is provided with a threaded hole 106, the threaded hole 106 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com