Medical air purification and degerming sterilizer

A technology of air purification and disinfection machine, which is applied in the direction of disinfection, air quality improvement, application, etc., and can solve the problem of slow penetration of disinfectant into the filter layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

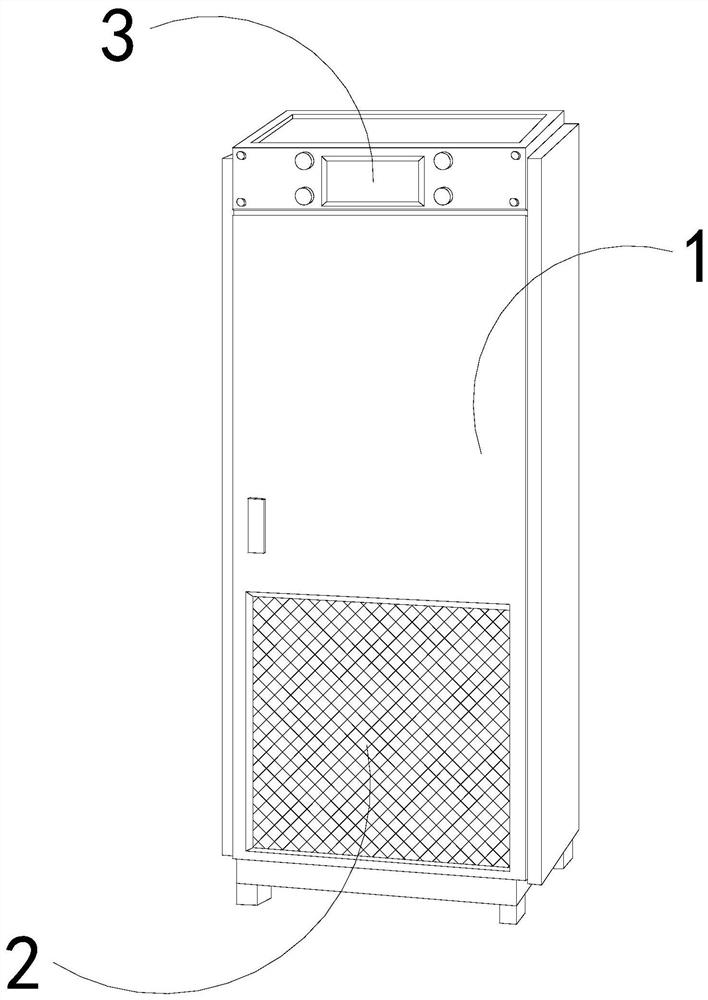

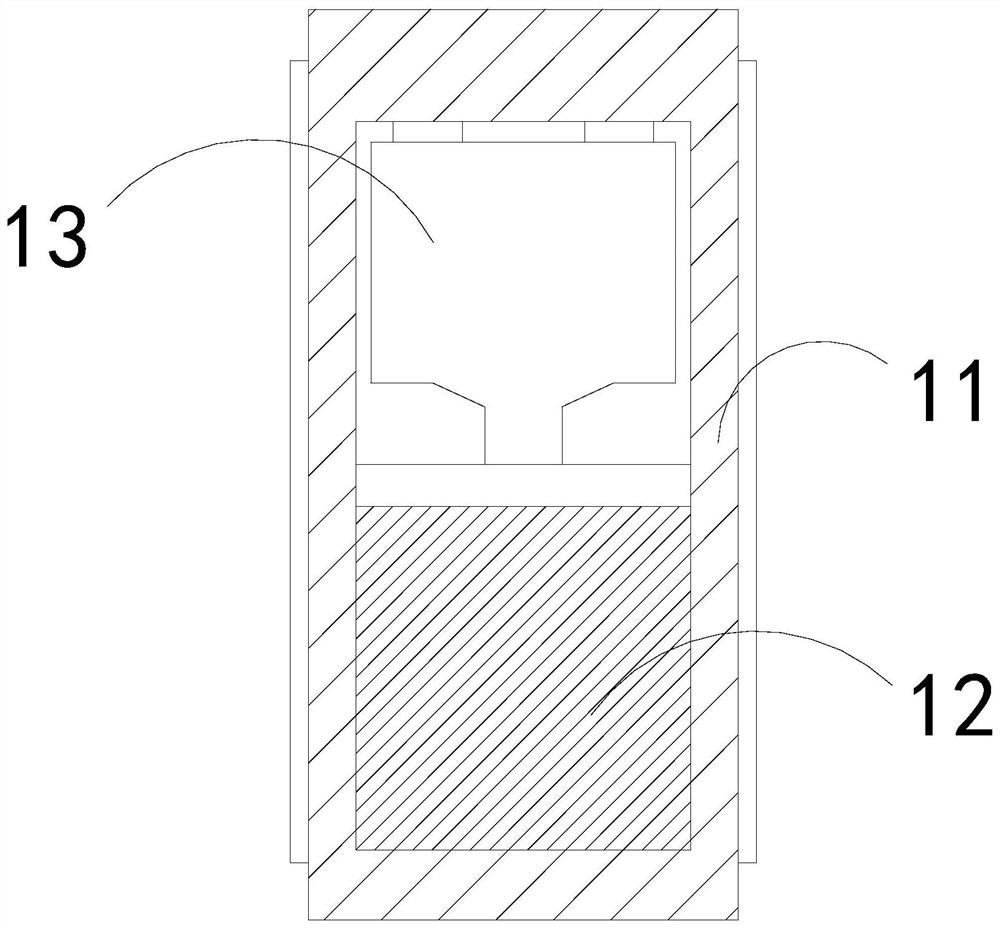

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The invention provides a medical air purification, sterilization and disinfection machine, the structure of which includes a body 1, an air intake plate 2, and a display screen 3, the display screen 3 is embedded and fixed at the front end of the body 1, and the body 1 is connected to the air intake The board 2 is an integrated structure; the body 1 includes an outer frame 11, a filter layer 12, and a liquid storage tank 13, the filter layer 12 is installed inside the outer frame 11, and the liquid storage tank 13 is embedded in the filter layer 12 upper end position.

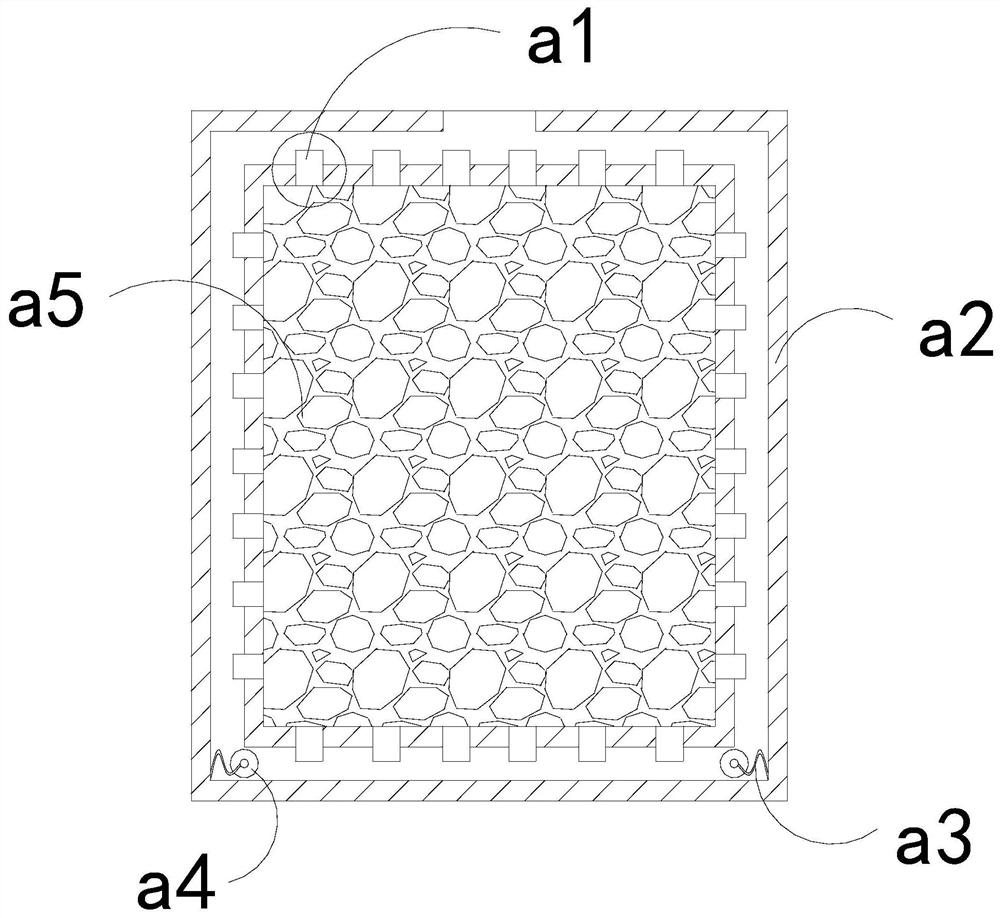

[0028] Wherein, the filter layer 12 includes an inner frame a1, an outer frame a2, a pull-back bar a3, an extruded ball a4, and a built-in block a5. The inner frame a1 and the outer frame a2 are an integrated structure, and the extruded ball a4 The pullback bar a3 is connected to the lower end of the inner wall of the outer frame a2, the built-in...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the extrusion ball a4 includes an outer expansion plate c1, a transition rod c2, a resilient piece c3, and a middle solid block c4, the outer expansion plate c1 is movably engaged with the middle solid block c4 through the transition rod c2, and the resilient piece c3 is installed between the inner side of the outer expansion plate c1 and the middle solid block c4. There are two outer expansion plates c1, and they are evenly distributed symmetrically outside the middle solid block c4. The extrusion generated between the plates c1 can make the outer expansion plate c1 expand outward with the cooperation of the transition rod c2.

[0036] Wherein, the outer expansion plate c1 includes a contact plate c11, an elastic ring c12, an intermediate connection ring c13, and a plate surface c14. The ring c13 is hinged. There are two contact plates c11, which are evenly distributed symmetrically on the plate surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com