Multifunctional milling cutter

A multi-functional milling cutter technology, applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of single function, low milling cutter strength, low efficiency, etc., to achieve increased strength, enhanced installation fixity, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

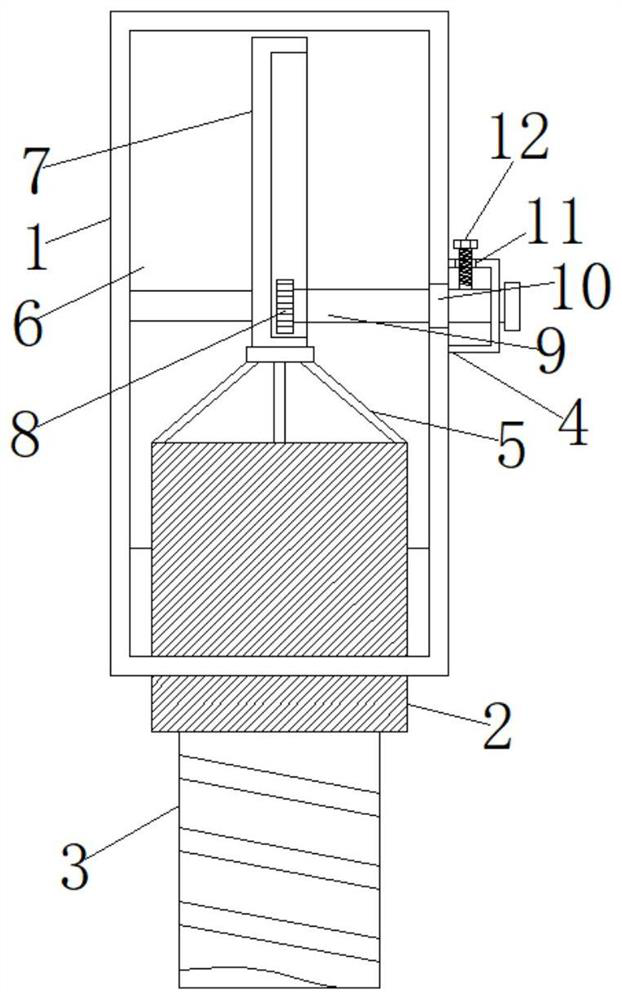

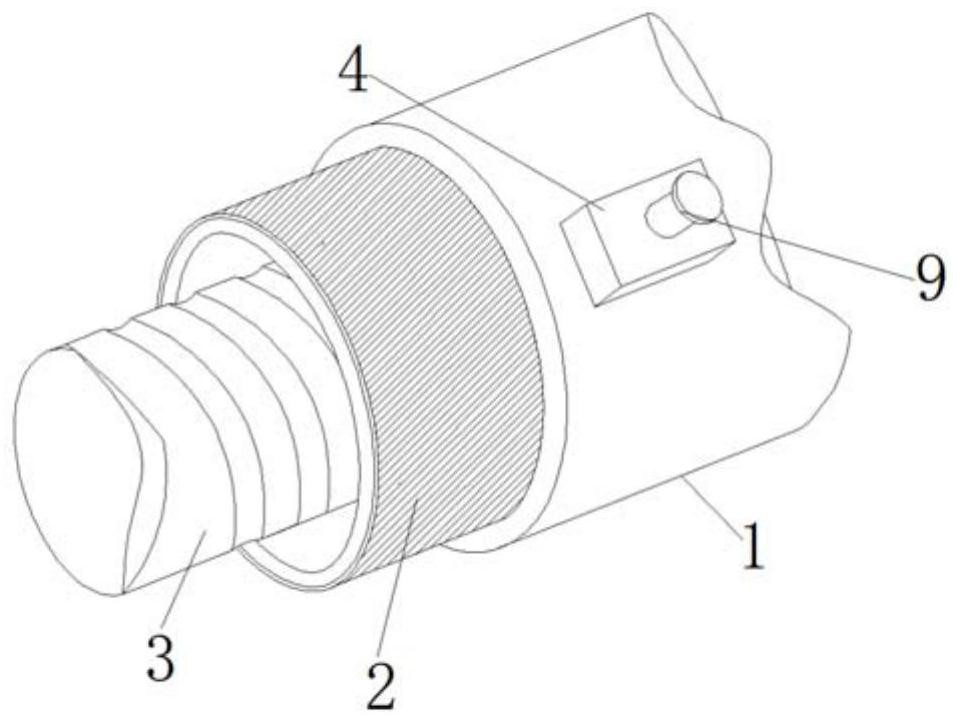

[0024] Embodiment 1, when the milling cutter is installed, the movable block 18 is inserted into the inside of the lace slot 17, and then the movable block 18 is rotated so that the second screw hole 20 is aligned with the second screw rod 19, and at the same time the convex surface of the movable block 18 is Compress with the concave surface of the lace slot 17, so that the movable block 18 is stuck in the inside of the lace slot 17, and then the second screw 19 is screwed to the inside of the second screw hole 20 to complete the installation of the tool bar 3. Reinforcement strengthens the fixity of the knife bar 3 and improves the strength of the knife bar 3 .

Embodiment 2

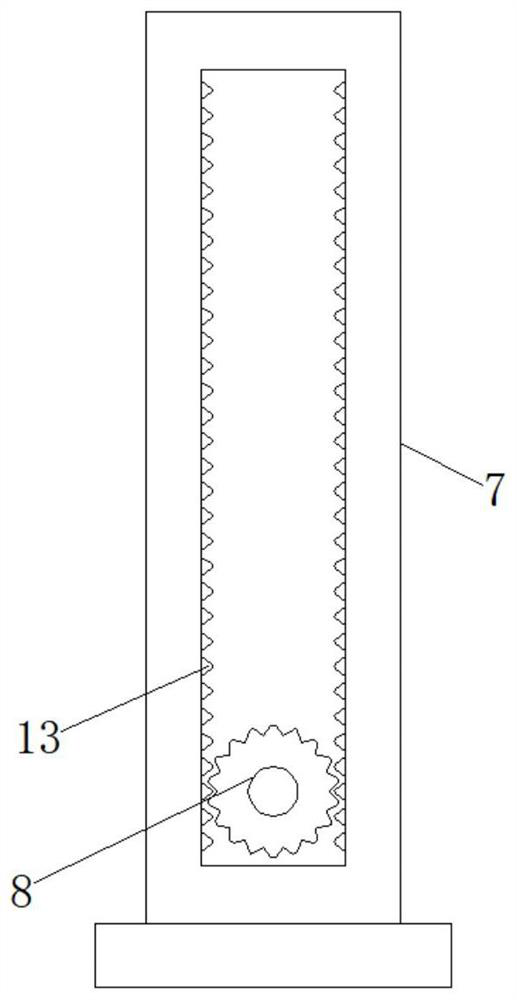

[0025] Embodiment 2, when the equipment is in use, the cutter bar 3 can be used for cutting processing, and the workpiece can also be polished through the grinding ring 2. After the user rotates the rotating shaft 9, the rotating shaft 9 drives the gear 8 to rotate, and acts on the rack 13 slides on the support bar with the sliding plate 7, so that the sliding plate 7 pushes the grinding ring 2 to slide inside the ring groove 15, so that the grinding ring 2 is placed outside the ring groove 15, and can also be retracted inside the ring groove 15 to adjust Conveniently, after tightening the first screw rod 12 afterwards, one end of the first screw rod 12 presses the rotating shaft 9, so that the position of the sliding plate 7 is fixed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap