A device for processing dried flowers and hay

A technology for making devices and hay, applied in special decorative structures, decorative arts and other directions, can solve the problems of fast pouring speed, uneven coverage, short storage time of flowers, etc., and achieve the effect of improving uniformity and ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

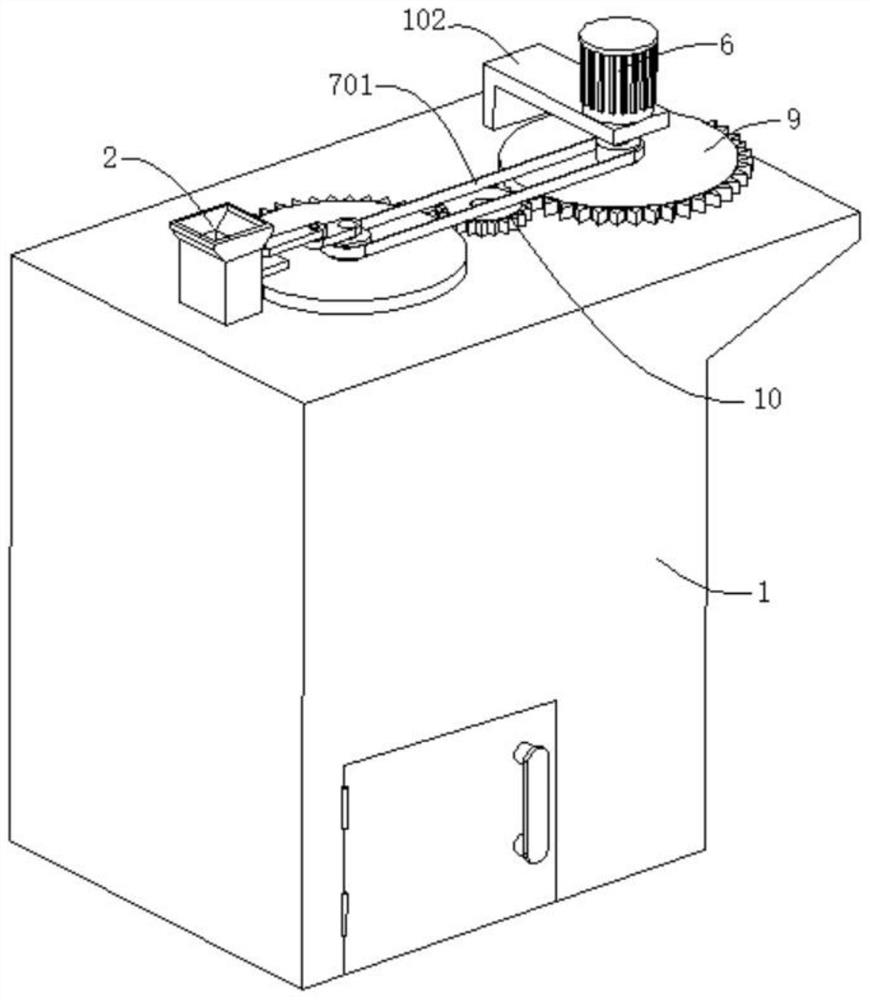

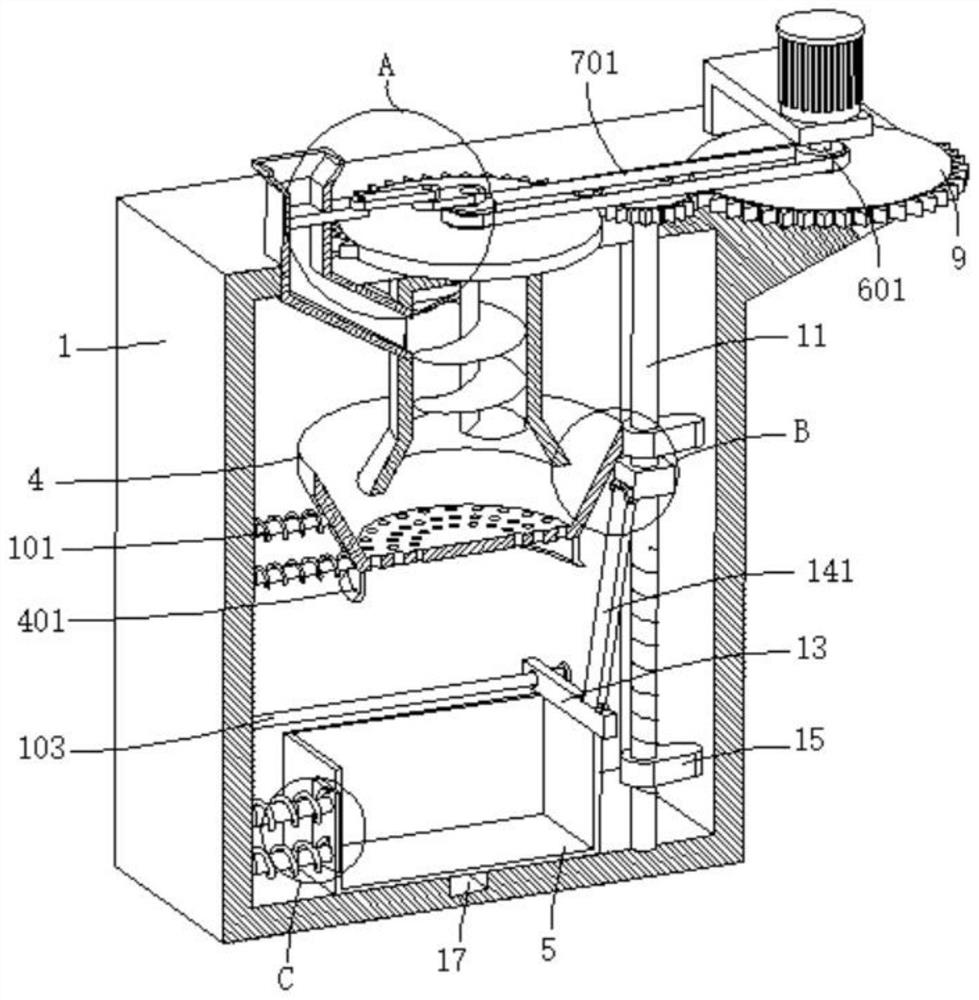

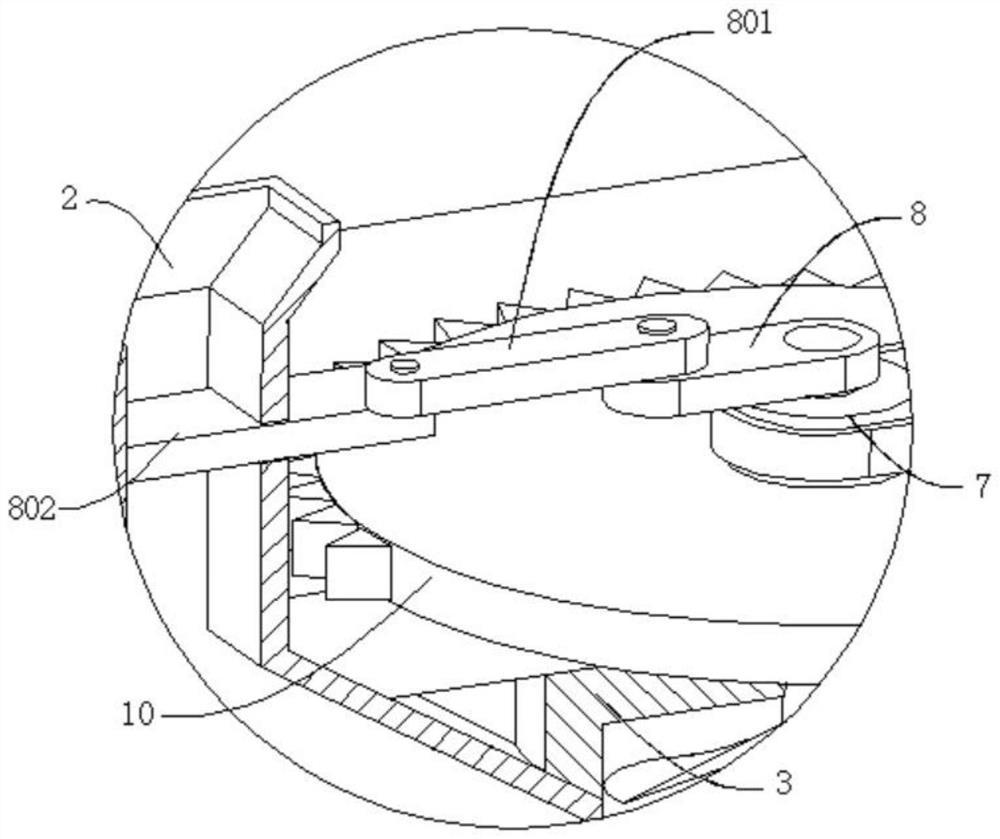

[0034] refer to figure 1 , figure 2 , image 3 and Figure 6 , a dried flower and hay processing and manufacturing device, comprising a box body 1, a feeding pipe 2 is connected to the top of the box body 1, a quantitative mechanism is movably connected in the feeding pipe 2, and a feeding pipe 3 is connected to the top inner wall of the box body 1, The feeding pipe 2 and the feeding pipe 3 communicate with each other, the inner wall of the box body 1 is connected with a connecting rod 101, and the end of the connecting rod 101 away from the inner wall of the box body 1 is connected with a screen tray 4, and the screen tray 4 is placed on the side of the feeding pipe 3. Bottom, the bottom inner wall of casing 1 is connected with making box 5, and making box 5 places the below of screen mesh dish 4, and the top of casing 1 is connected with support seat 102, and support seat 102 outer wall is fixedly connected with motor 6, and the motor 6 The output end is connected with a...

Embodiment 2

[0037] refer to figure 1 , figure 2 , image 3 and Figure 6 , a dried flower and hay processing and manufacturing device, comprising a box body 1, a feeding pipe 2 is connected to the top of the box body 1, a quantitative mechanism is movably connected in the feeding pipe 2, and a feeding pipe 3 is connected to the top inner wall of the box body 1, The feeding pipe 2 and the feeding pipe 3 communicate with each other, the inner wall of the box body 1 is connected with a connecting rod 101, and the end of the connecting rod 101 away from the inner wall of the box body 1 is connected with a screen tray 4, and the screen tray 4 is placed on the side of the feeding pipe 3. Bottom, the bottom inner wall of casing 1 is connected with making box 5, and making box 5 places the below of screen mesh dish 4, and the top of casing 1 is connected with support seat 102, and support seat 102 outer wall is fixedly connected with motor 6, and the motor 6 The output end is connected with a...

Embodiment 3

[0041] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 , a dried flower and hay processing and manufacturing device, which is basically the same as that of Embodiment 2, furthermore, the outer wall of the rotating rod 301 and the rotating shaft 601 is connected with a driving gear 9, and a driven gear 10 is meshed between the two driving gears 9 A screw rod 11 is connected to the bottom wall of the driven gear 10, and the screw rod 11 is rotatably connected in the box body 1 through a third bearing.

[0042] A first cam 12 is connected to the outer wall of the screw rod 11, and the first cam 12 is movable against the screen disc 4, and the connecting rod 101 is configured as a spring telescopic tube.

[0043] The bottom wall of the screen tray 4 is connected with an extension piece 401 .

[0044] Both driving gears 9 are set as incomplete gears.

[0045] Squeeze the screen disc 4 by the first cam 12, the desiccant falling in the screen disc 4 can be ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com