Preparation method of single-component vulcanized electric conduction silica gel

A conductive silicone, one-component technology, applied in the direction of coating, etc., can solve the problems of difficult to control the size of conductive silicone, affect the quality of conductive silicone, and the performance of conductive silicone is not stable enough, so as to ensure the preparation effect, simplify the strip operation, and ensure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

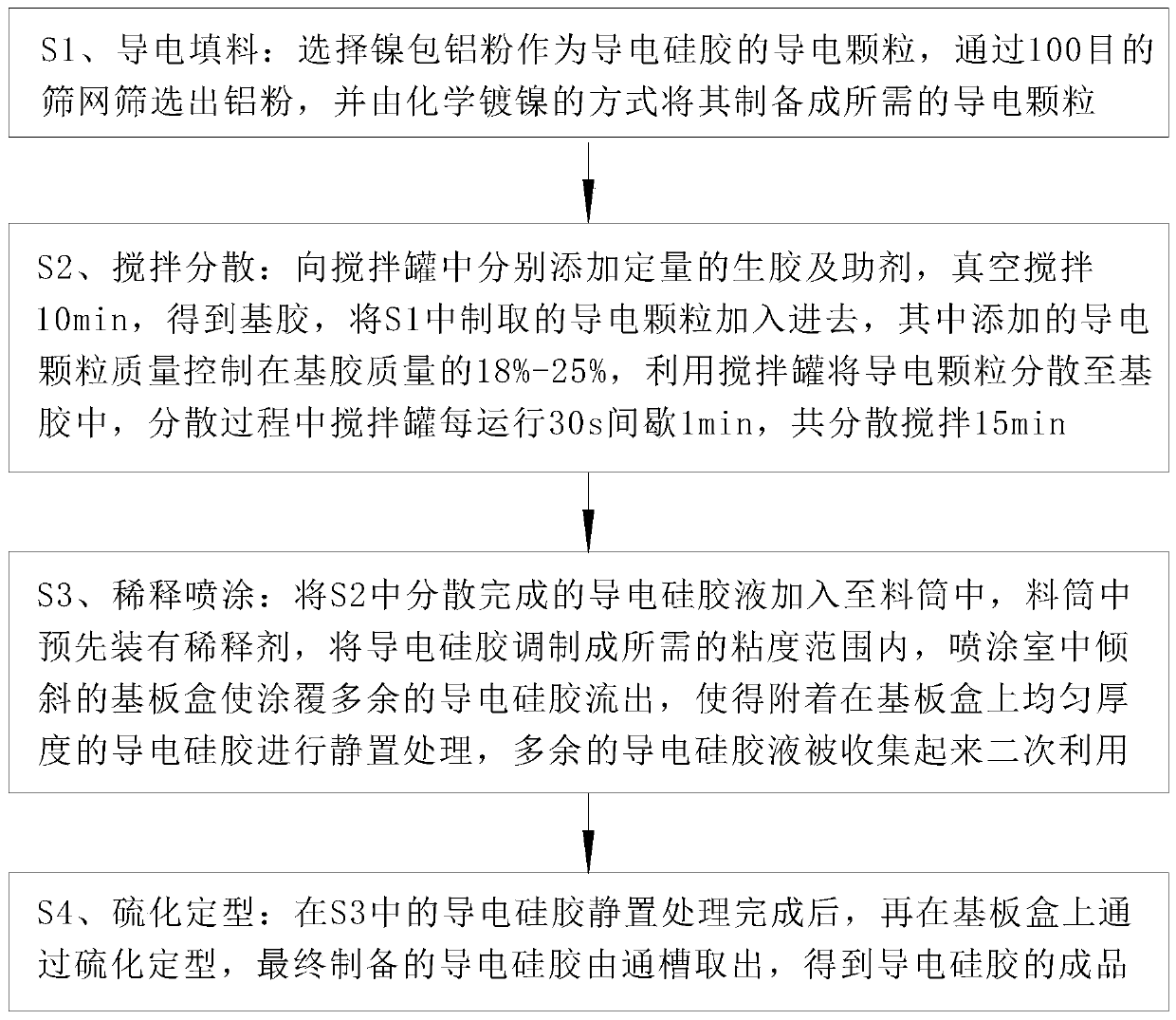

[0032] Such as Figure 1 to Figure 8 Shown, the preparation method of a kind of one-component vulcanized conductive silica gel of the present invention, the method step is as follows:

[0033] S1. Conductive filler: Select nickel-coated aluminum powder as the conductive particles of conductive silica gel, screen the aluminum powder through a 100-mesh screen, and prepare it into the required conductive particles by electroless nickel plating; the conductive particles are prepared on conductive silica gel Pre-production can ensure the purity of conductive particles, prevent the contamination of conductive particles during storage, and ensure the quality of conductive particles in conductive silica gel;

[0034] S2. Stirring and dispersing: add a certain amount of raw rubber and additives to the mixing tank, and stir in a vacuum for 10 minutes to obtain the base rubber. Add the conductive particles prepared in S1, and the quality of the added conductive particles is controlled at...

Embodiment approach

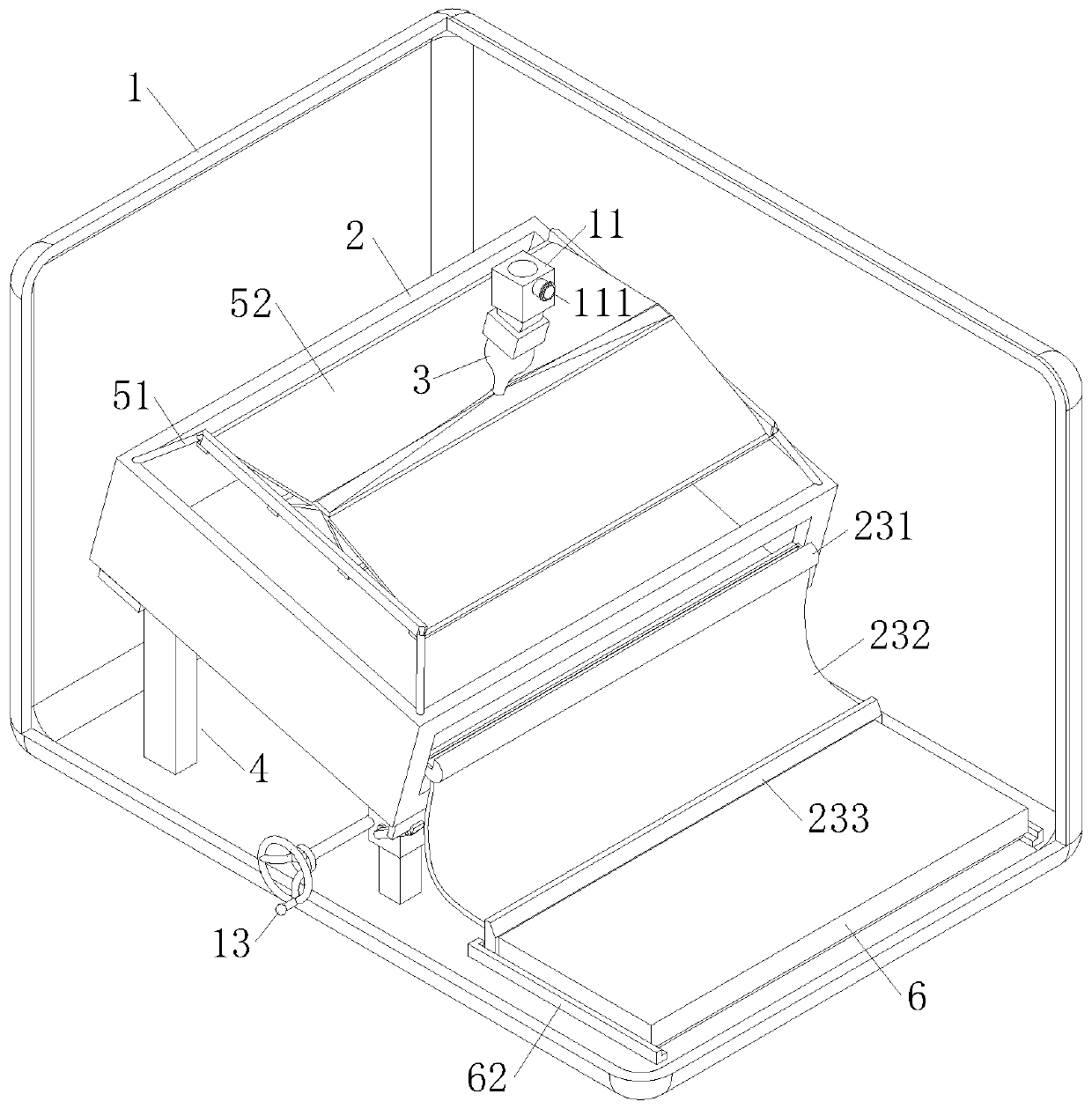

[0038] As an embodiment of the present invention, the baffle 23 is provided with a grooved tube 231, and the grooved tube 231 is located at the end of the baffle 23 facing the outside of the substrate box 2; the bottom of the grooved tube 231 is provided with a flexible extension tube 232 , the end of the extension tube 232 is provided with a clip 233; the other end of the clip 233 is provided with a collection box 6, the collection box 6 is connected with the extension tube 232 through the clip 233, and the collection box 6 is located in the housing 1 corresponding to the flip cover 14 Inside: the excess conductive silicone liquid flowing out through the through groove 22 of the substrate box 2 still has the value of reuse, but the specifications of the prepared conductive silica gel are different, and it is necessary to change the protruding height of the baffle plate 23 in the through groove 22, so that the conductive silicone liquid The outflow position changes accordingly;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com