Front suspension precoated sand mold

A technology of coated sand and front suspension, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of excessive waste, unreasonable exhaust groove setting, and affecting sand mold production, so as to improve economic benefits and carry Smooth, weight-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments. For the convenience of description, the positions of "upper", "lower", "left" and "right" are described in the orientations shown in the drawings of the description, but the implementation of the present invention The approach is not limited to this description of a fixed orientation.

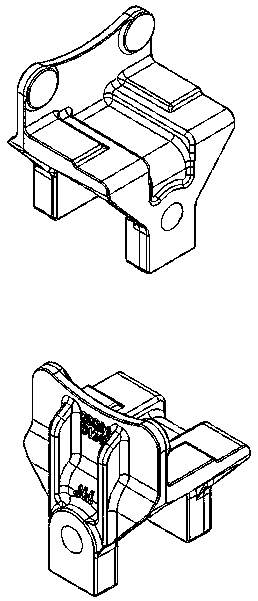

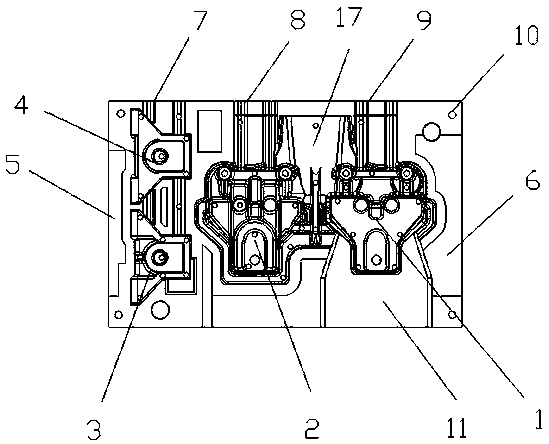

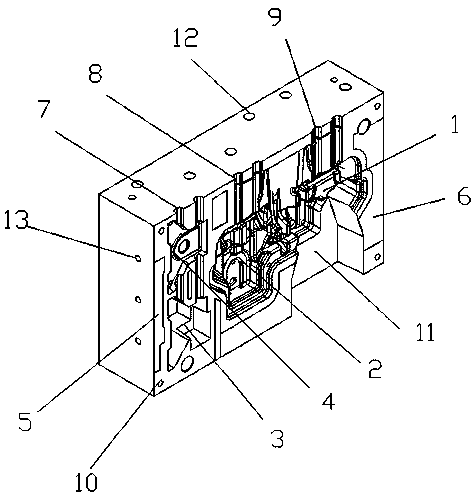

[0024] A kind of front suspension film-coated sand mold is made up of die, punch and runner, and described die fits with described punch, and both are superimposed to form mold integral body, and runner (such as Figure 8 shown) is placed in the runner cavity 17 of the die, such as Figure 2~4 As shown, the front of the die is depressed to form four chambers of different shapes, which are side middle chamber 1, center chamber 2, side lower chamber 3 and side upper chamber 4, wherein the side lower chamber 3 and the side upper chamber The cavities 4 are located side by side on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com