A new synthetic fiber cotton molding method and processing equipment

A synthetic fiber and molding technology, applied in the field of brand-new synthetic fiber cotton molding methods and processing equipment, can solve the problems of not being able to produce products with complex shapes, not having too many pieces, and not being complicated in paving and filling operations. , to achieve the effect of realizing the processing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

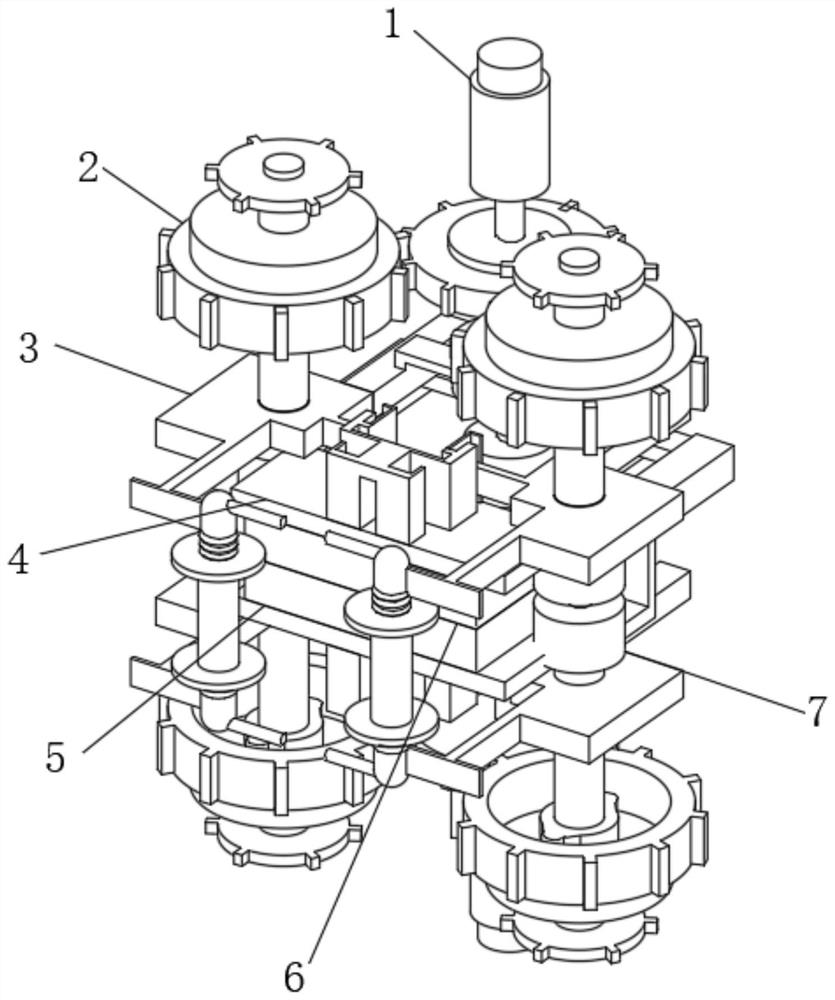

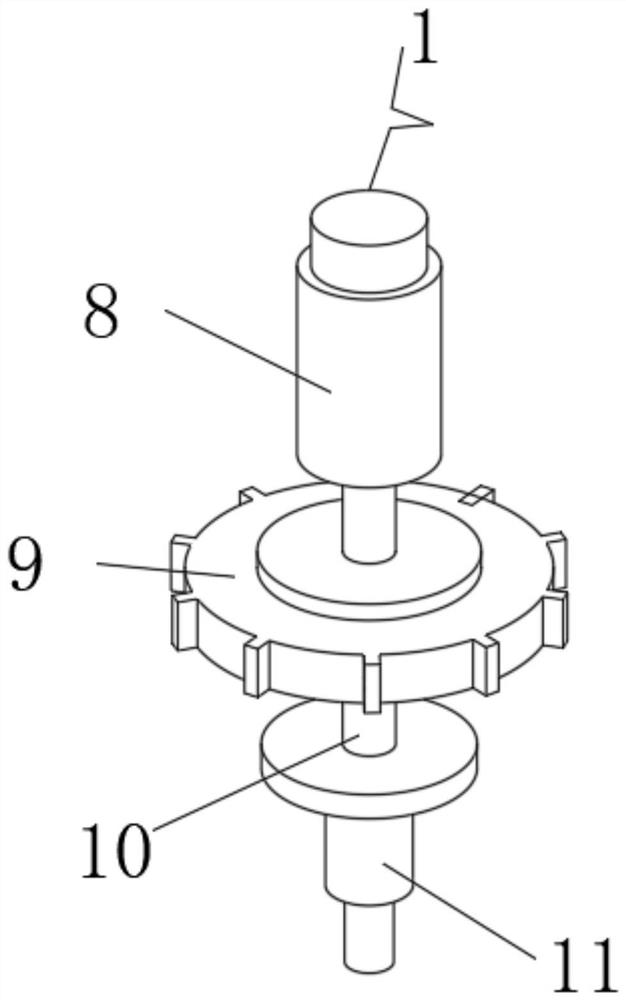

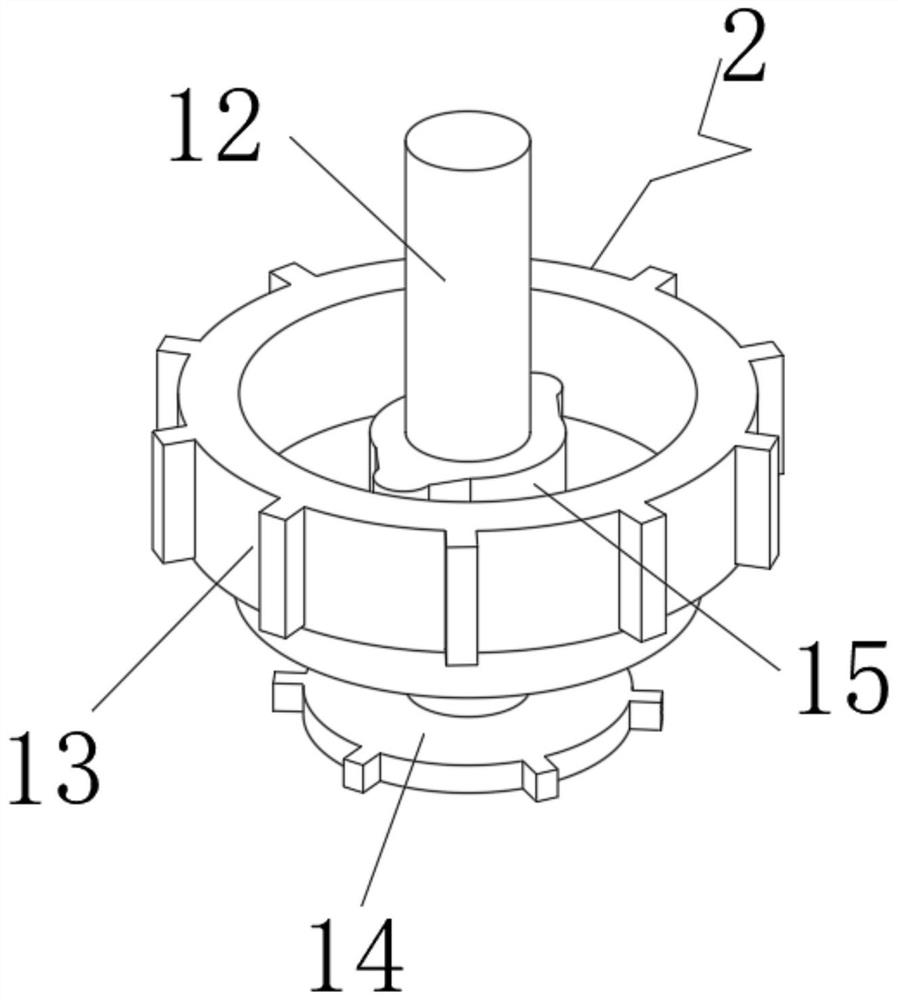

[0043] A brand new synthetic fiber cotton molding processing equipment, such as Figure 1-8 As shown, it includes a transmission device 1, a transmission device 2 is rotatably connected to the side end position of the transmission device 1, the lower end of the transmission device 2 is connected to a limit device 3, and a connection device 4 is clamped at the squat position of the limit device 3. , the lower end of the connecting device 4 is fixedly connected with the upper die 6, the lower end of the upper die 6 is in contact with the lower die 5, the central rear end of the transmission device 1 and the transmission device 2 are inserted with a fixing device 7, and the transmission device 1 Including the motor 8, the first toothed plate 9, the connecting shaft 10 and the plug-in shaft 11, the motor 8 is installed on the top of the inner end of the transmission device 1, the lower end of the motor 8 is rotatably connected with the first toothed plate 9, the center of the first...

Embodiment 2

[0047] On the basis of Example 1, as Figure 9-10 As shown, the lower mold 5 also includes a first communication pipe 34, a first square pipe 35 and a first outer pipe 36. The first communication pipe 34 is provided at the side end of the first airtight cover 24, and the first communication pipe 34 passes through The first square pipe 35 is communicated with the first outer pipe 36, and the upper mold 6 also includes a second communication pipe 37, a second square pipe 38 and a second outer pipe 39. The second communication pipe 37 is provided in the second airtight cover. 27 , the second communication pipe 37 is communicated with the second outer pipe 39 through the second square pipe 38 .

[0048] When this embodiment is in use, the first communication pipe 34, the first square pipe 35 and the first outer pipe 36, which are additionally provided at the inner end of the lower mold 5, and the second communication pipe 37, the first outer pipe 36, and the second communication p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com