Axial pulse vortex ring generation device based on positive and negative pressure alternating closed chamber deformation

A closed chamber and generating device technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problems of inconvenient short-term high speed, intermittent disturbance, motor performance can not be maximized, vortex ring ventilation can not meet the requirements, etc. , to achieve the effect of improving the space utilization rate of the device and the dynamic balance effect, improving the effect of the vortex ring, and meeting the minimum ventilation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

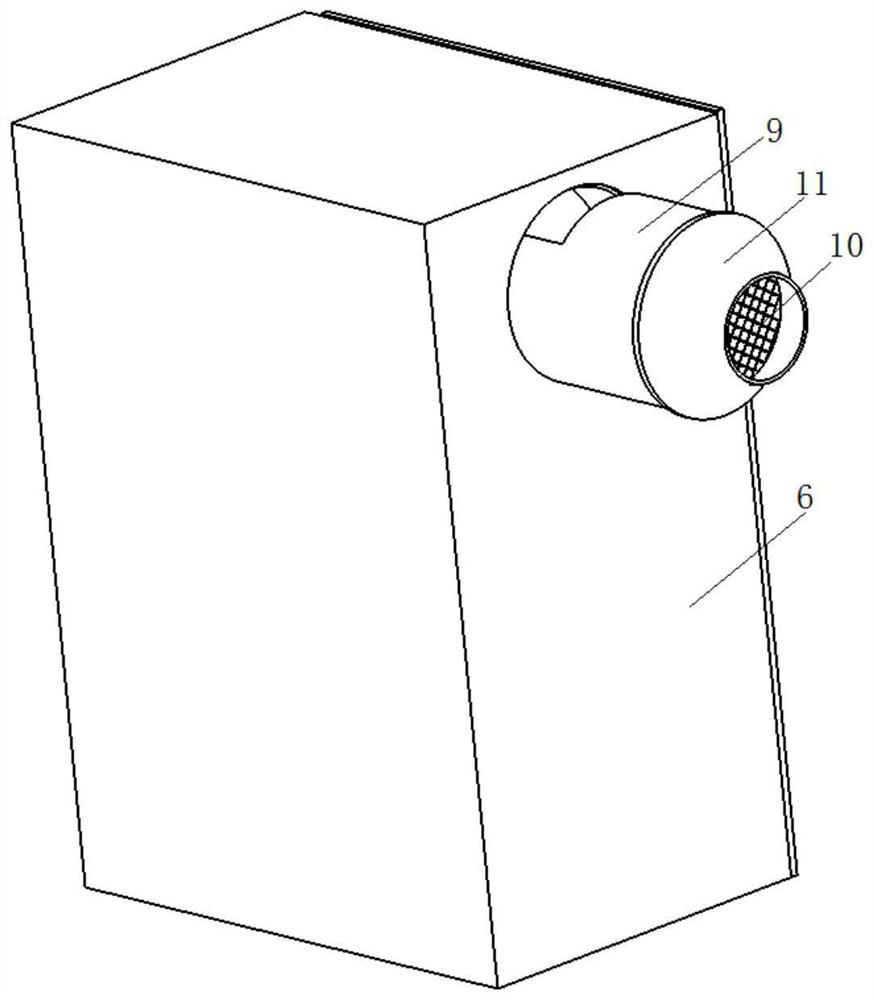

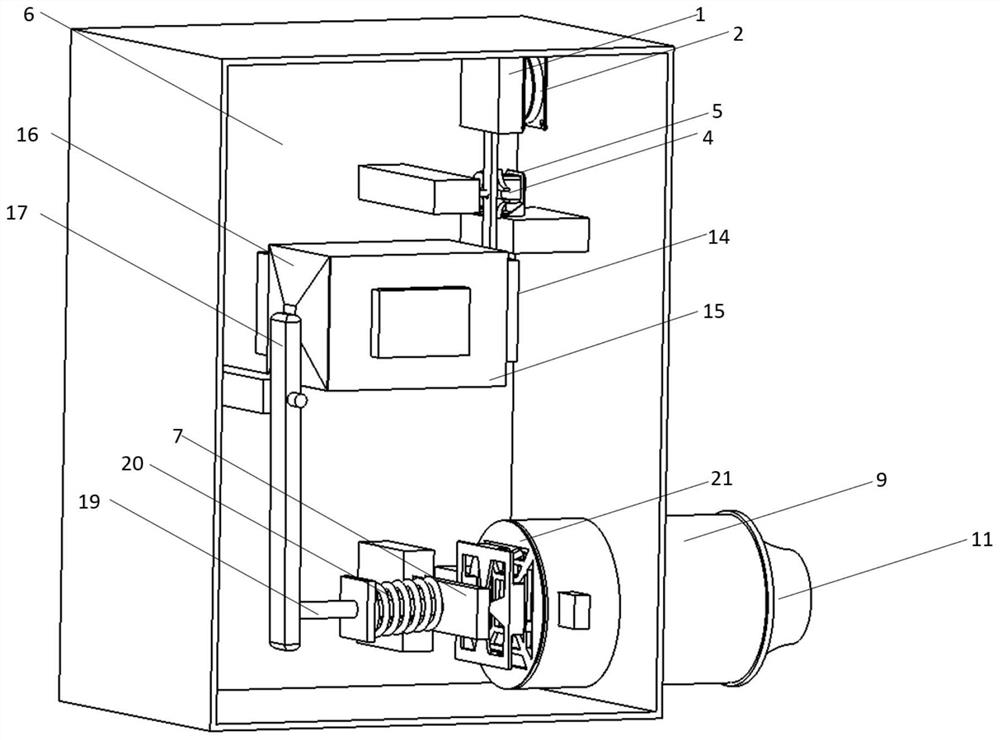

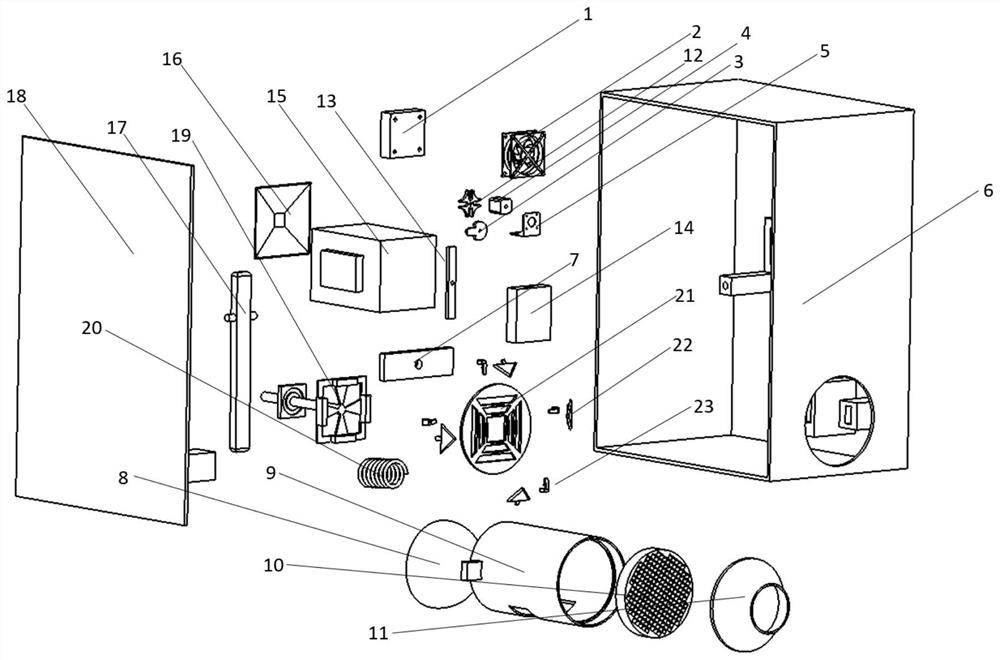

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] refer to Figure 1 to Figure 10 As shown, the axial pulse vortex ring generating device based on the deformation of the positive and negative pressure alternating airtight chamber in an embodiment provided by the present invention includes a fixed frame, a ventilation device, a disturbance device and a power device, and the ventilation device and the disturbance device Both the power device and the power device are fixed on the fixed frame, and the power device is connected with the elastic film 8 in the ventilation device through the disturbance device;

[0034] The power device includes a metal strain gauge 16, a positive and negative pressure generating chamber 15, and an alternating cold and heat mechanism. The metal strain gauge 16 is arranged at one end of the positive and negative pressure generating chamber 15, and the metal strain gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com