Multi-parameter online comprehensive detection device for variable diameter aviation hydraulic pipeline

A hydraulic pipeline and comprehensive detection technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as affecting efficiency, changing pipe diameters, and difficulty in disassembly and assembly, and achieve the effect of increasing accuracy and reliability and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

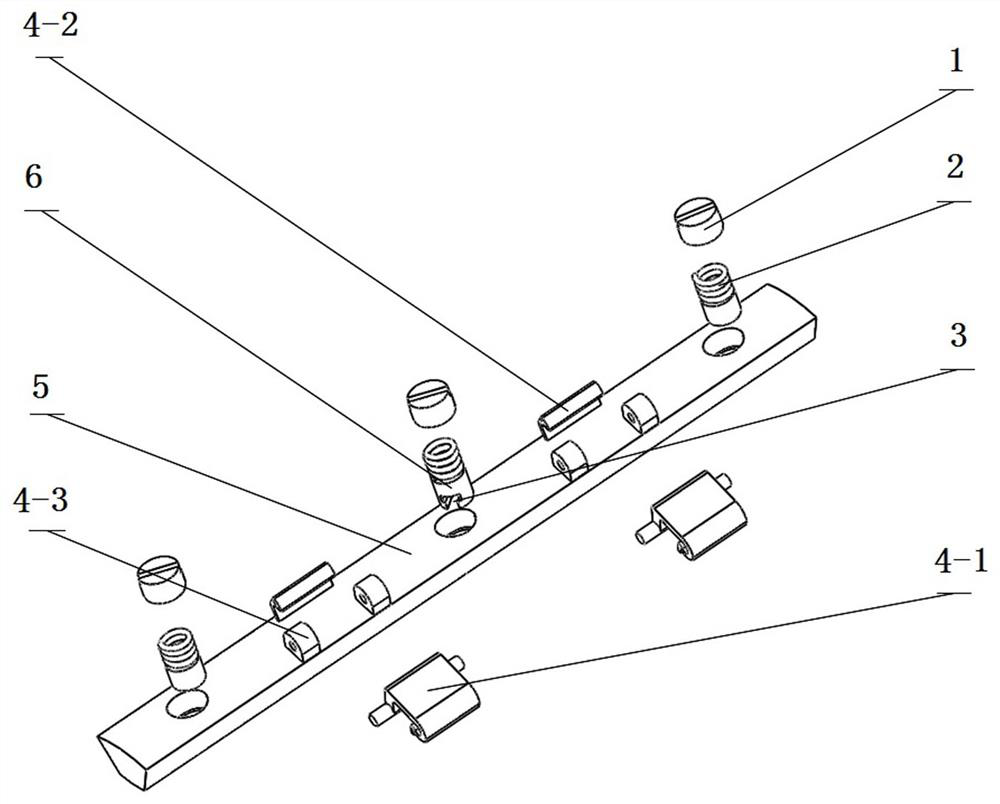

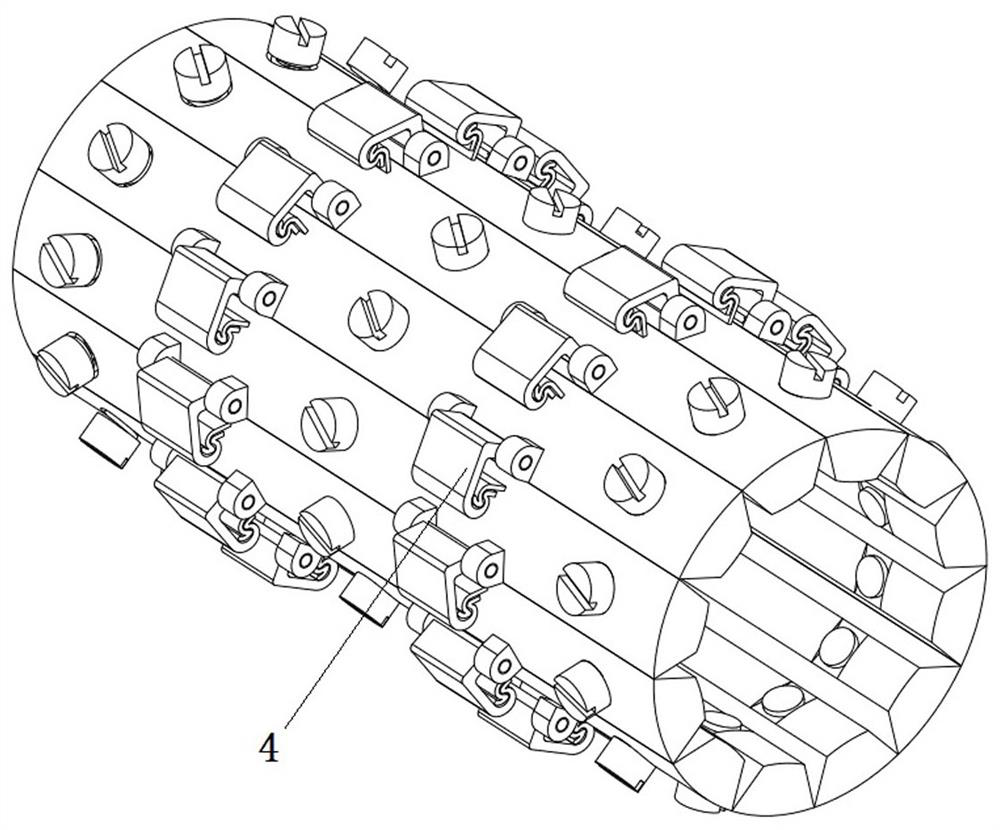

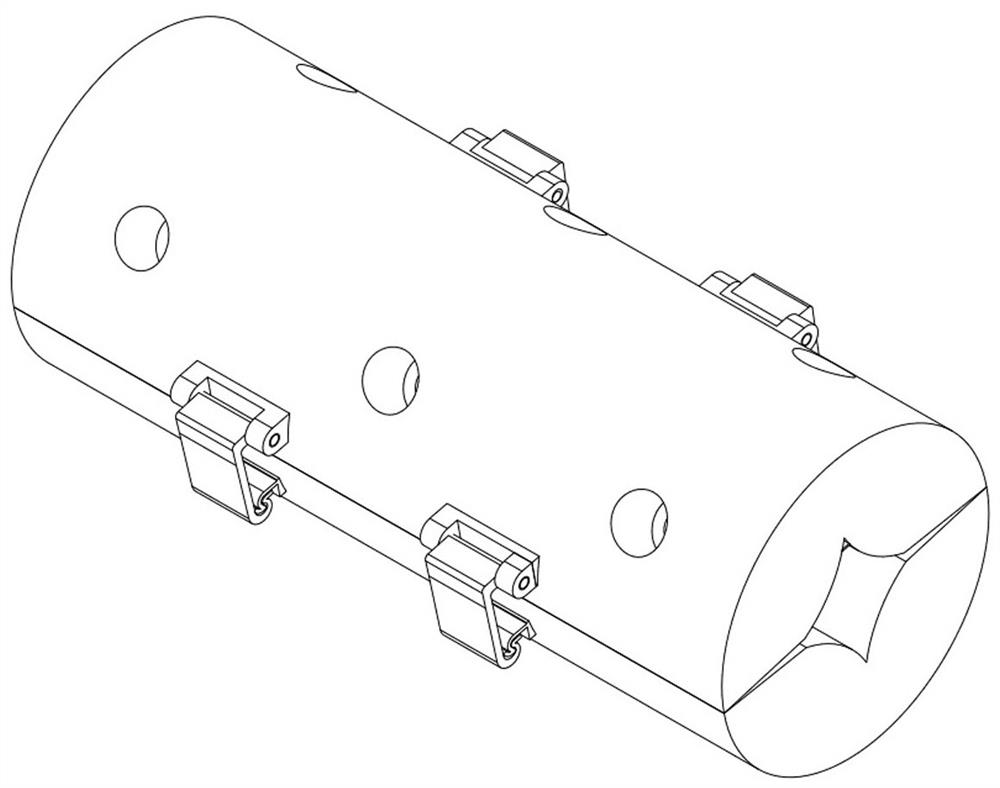

[0039] like figure 1 As shown, the spring 2 is connected with one end of the sensor base 6 ; the sensor is fixed on the sensor base 6 ; the positioning bolt 1 is pressed against the spring 2 . Assemble the selected sensor, sensor base 6, spring 2, and positioning bolt 1 in sequence, pull the sensor circuit through the gap between each main body 5 and connect it to the signal processor, and install the main body 5 according to the appropriate number on the female. Buckle 4-1, and tighten the positioning bolt 1 with a certain pre-tightening force to ensure the accuracy and reliability of the measurement data. like figure 2 The connection shown in this scheme can test different parameters of the hydraulic pipeline with large diameter and multiple measuring points at the same time. like image 3 The connection shown in this scheme can test different parameters of the hydraulic pipeline with small diameter and multiple measuring points at the same time.

[0040] According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com