Rotary gripper device for grabbing more by one gripper

A technology of rotating grippers and grippers, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of high manufacturing cost and low equipment production capacity, achieve low cost, increase production capacity, and meet market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

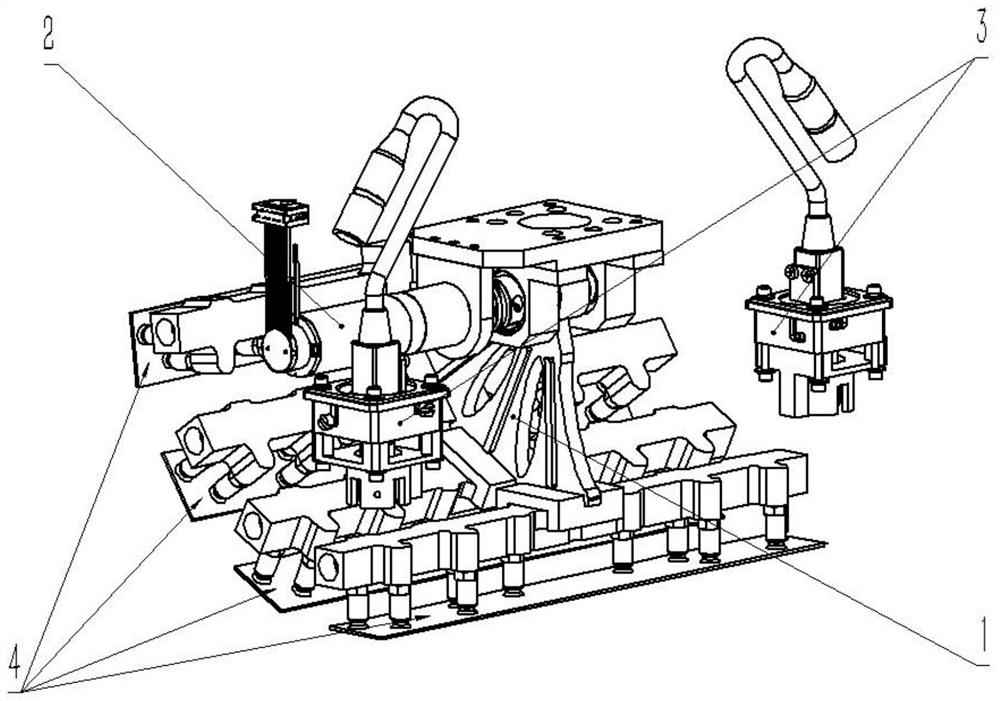

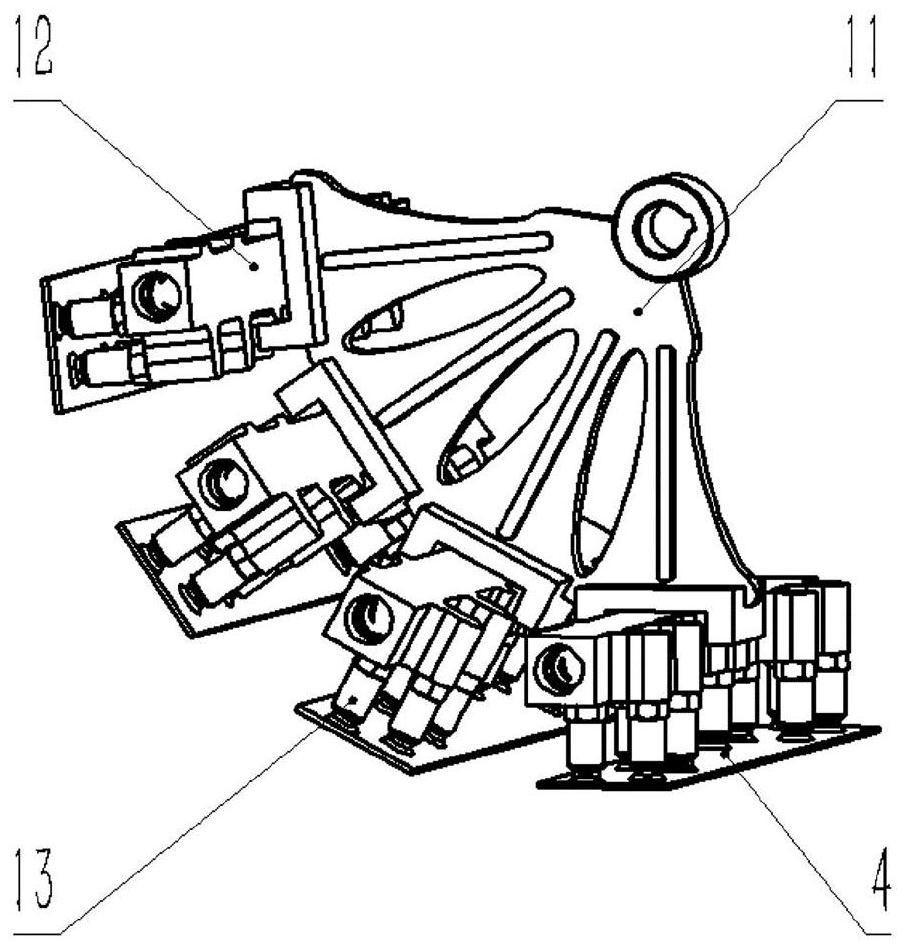

[0028] A rotary gripper device for one grasping multiple, the device comprises a single grasping multiple gripper 1, a driving device 2, and a visual device 3, and is characterized in that: the one grasping multiple gripper 1 is connected with the driving device 2, so that The driving device 2 is installed on the manipulator, the visual device 3 is located above or below the detection area of the object to be absorbed 4, and the two are separated by a certain space; A suction cup mounting plate 12, several suction cups 13 and other parts, the suction cup mounting plate 12 is uniformly installed on the special-shaped plate 11 at a certain angle, and the suction cup 13 is installed on the suction cup mounting plate 12 above; the aspirated object is transported to the film taking position, the servo motor rotates so that a certain suction cup mounting plate of the one-grip multi-rotation gripper is parallel to the aspirated object, and the manipulator descends to make the suctio...

Embodiment 2

[0030] The one-grip and multi-rotation gripper device used in the production of photovoltaic modules according to the present invention is beneficial to the improvement of equipment production capacity in the production of photovoltaic modules.

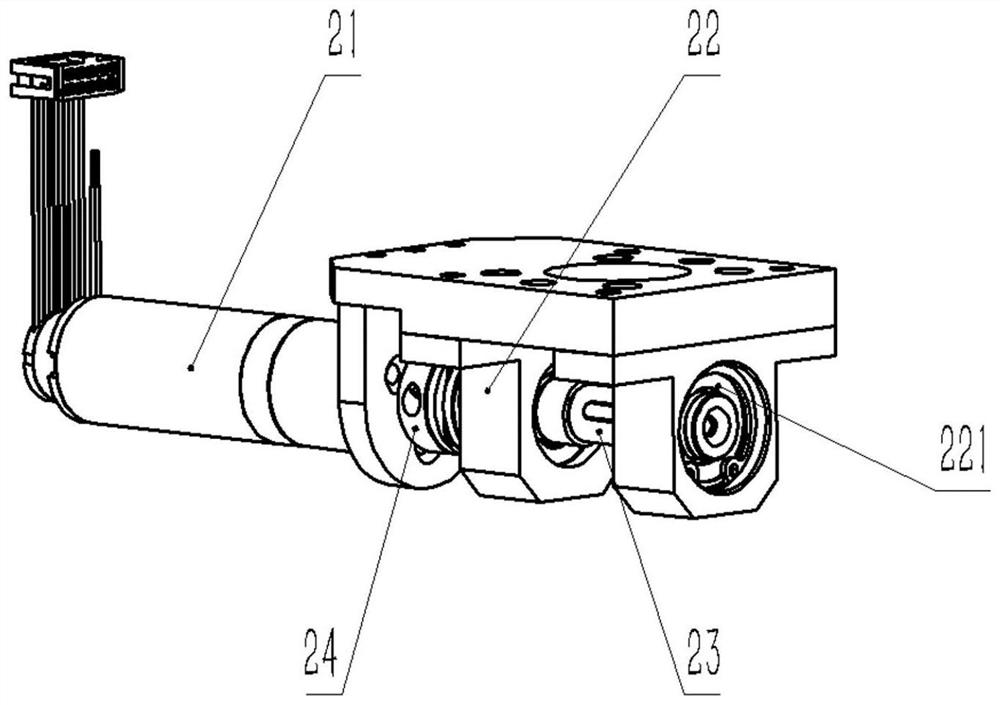

[0031] The one-grab and multi-rotation gripper device includes a prime mover 21, which is composed of a servo motor and a reducer. The prime mover 21 is coaxially connected with the drive shaft 23 through a connecting body 24, and the connecting body 24 can be various types of shaft couplings. The drive shaft 23 is provided with a keyway, the prime mover 21 is installed on one side of the mounting frame 22, and the mounting frame 22 is provided with a rolling body 221 to reduce friction and prolong the life of the device. The rolling body 221 can be a deep groove ball bearing Or other types of bearings, the upper surface of the installation frame 22 is connected with the manipulator, and the manipulator can be a multi-axis manipulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com