High-bearing airfoil joint load transferring structure

A high load-bearing and airfoil technology, applied in the fuselage frame, fuselage, transportation and packaging, etc., can solve the problems of loss of load-bearing capacity, effective transfer of airfoil structure, failure of connection interface structure, etc., to achieve the ultimate airfoil load-bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solution of the present invention more comprehensible, specific embodiments and accompanying drawings are described in detail as follows.

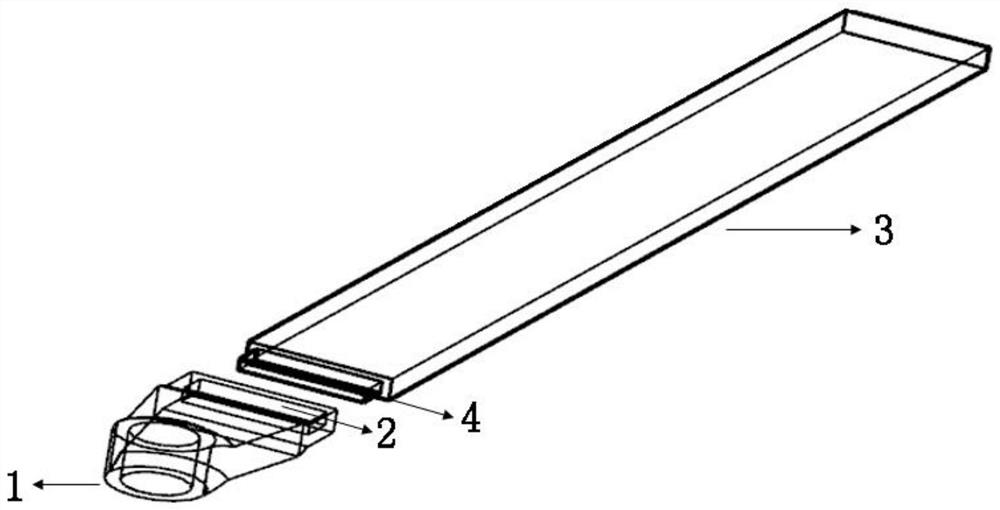

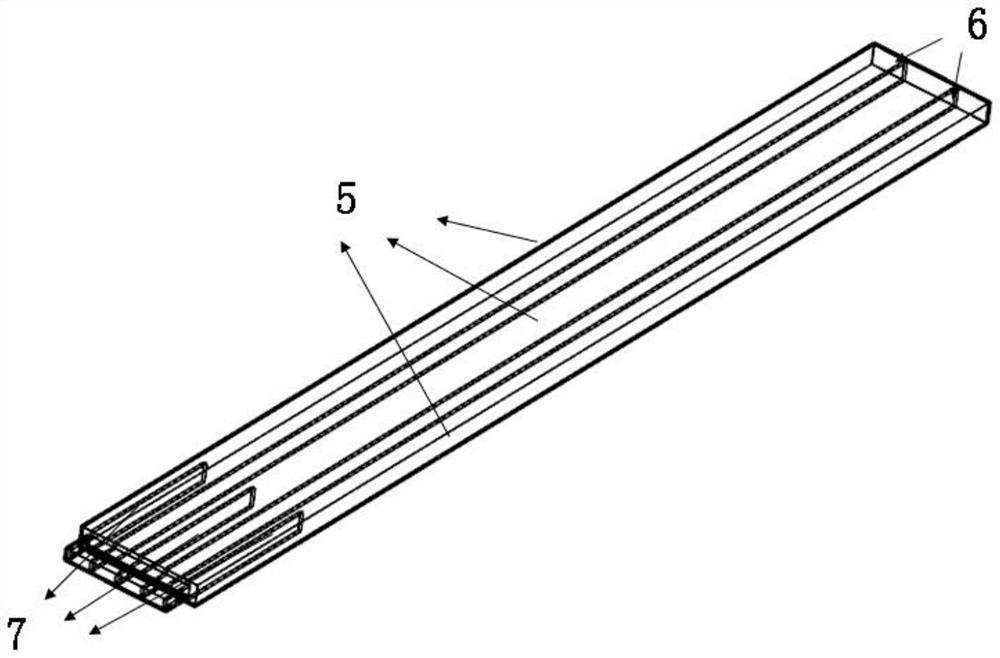

[0024] This embodiment discloses a load-carrying structure of a high-load airfoil joint, such as figure 1 As shown, it includes a metal joint 1 and a composite material girder 3, and the specific description is as follows.

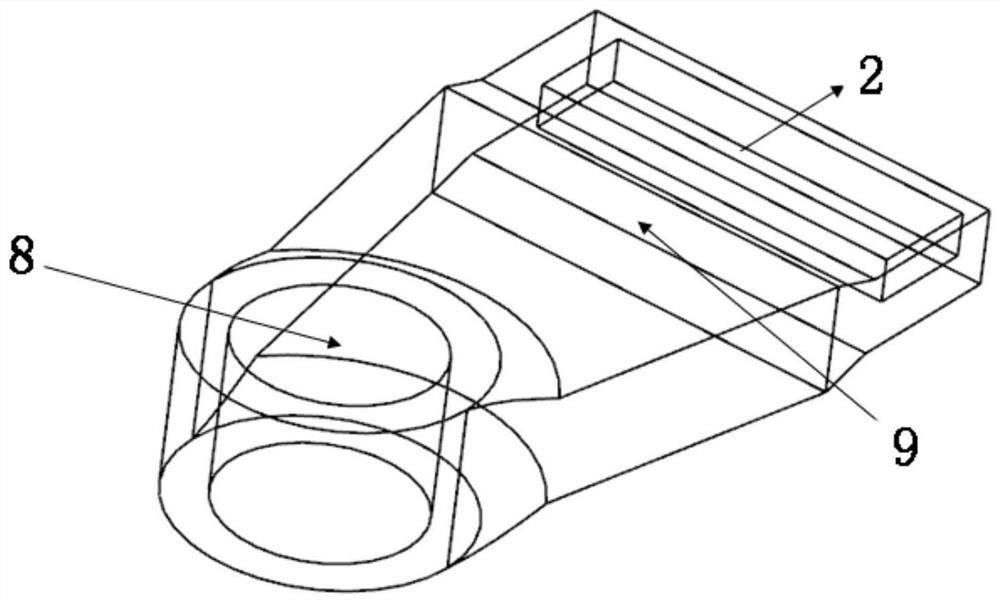

[0025] The metal joint 1 includes a fuselage connection interface 8 at one end and a girder connection surface at the other end, the girder connection surface contains a groove 2, and the structure is as follows figure 2 shown. One side of the metal joint 1 contains an airfoil connection area 9 . The thickness of the end where the fuselage connection interface 8 of the metal joint 1 is located is greater than the thickness of the end where the girder connection surface is located, so as to effectively increase the structural bending section coefficient and enhance the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com