Casting mold locating and locking structure of vertical centrifugal casting machine

A vertical centrifuge and locking structure technology, applied in the field of centrifugal casting, can solve the problems of troublesome positioning operation, inconvenient disassembly and assembly, low production efficiency, etc., and achieve the effects of avoiding strength failure, avoiding top spray and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

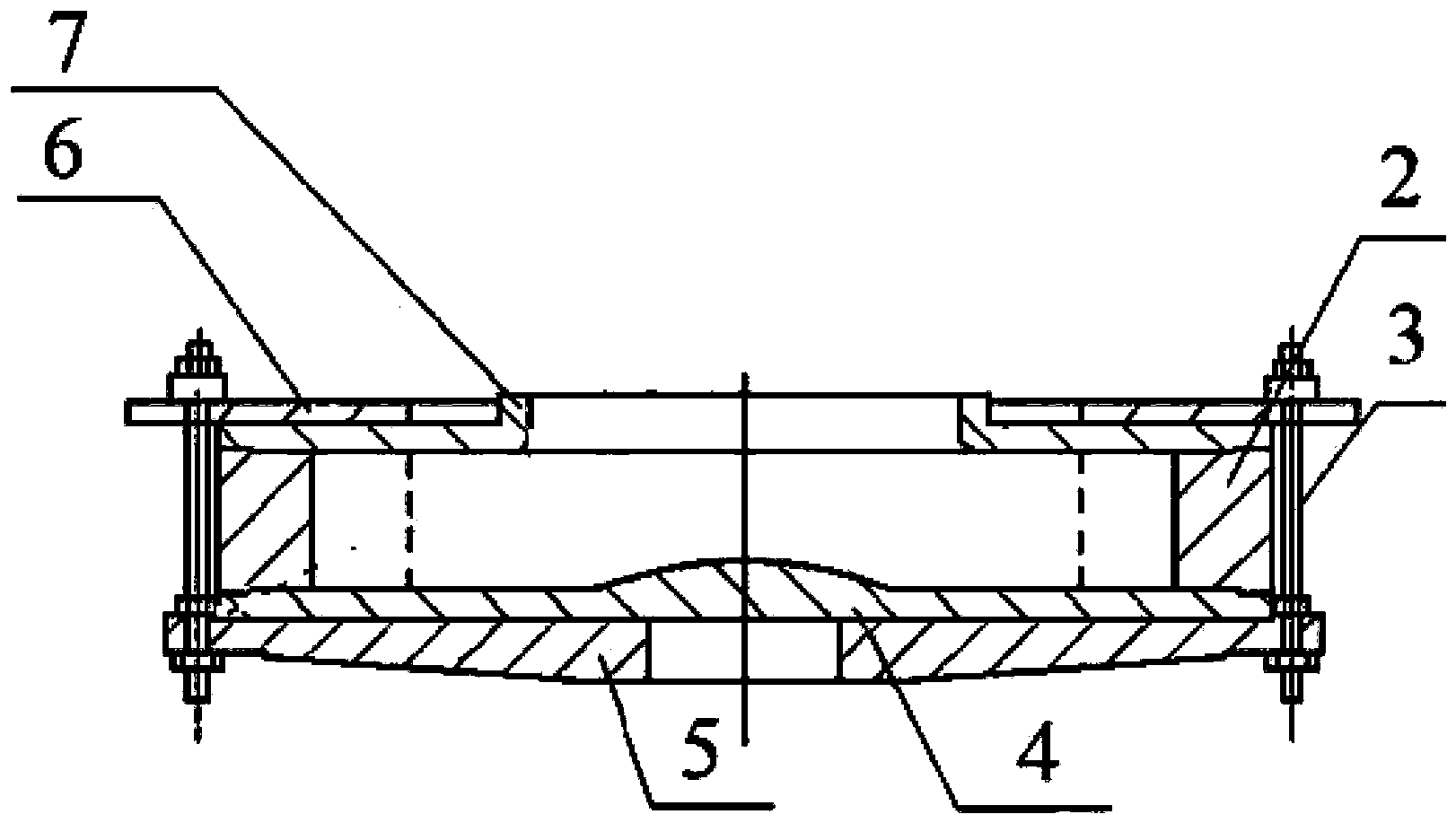

[0023] A J5520B vertical centrifugal casting machine related to the embodiment of the present invention has a main motor with a power of 75kW, a maximum spindle speed of 500rpm, and stepless speed regulation. This equipment is suitable for small batch production of single pieces. The size range of castings that this centrifuge can produce: the maximum outer diameter is Ф2000mm, the maximum height is 500mm, and the load capacity of the centrifuge chassis is W (W=W 铸件 +W 铸型 ) within 10t. The whole equipment (including the chassis) is installed in the reinforced concrete pit below the ground level, and the casting mold is installed in the reinforced concrete protective wall above the ground level, and the steel plate protection system is installed on it. The steel plate protection system consists of two protective covers, one big and one small. The large protective cover is a fixed structure and is mainly used for installation of equipment. The small protective cover is mainly u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com