Jacking device used for mounting of steel structure net rack and using method of jacking device

A lifting device and steel structure technology, which is applied in the direction of lifting device, lifting equipment safety device, packaging, etc., can solve the problems of time-consuming and laborious, and the lifting device does not have an automatic feeding mechanism, so as to reduce the number of workers and increase the consumption of food. Safety, the effect of speeding up the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

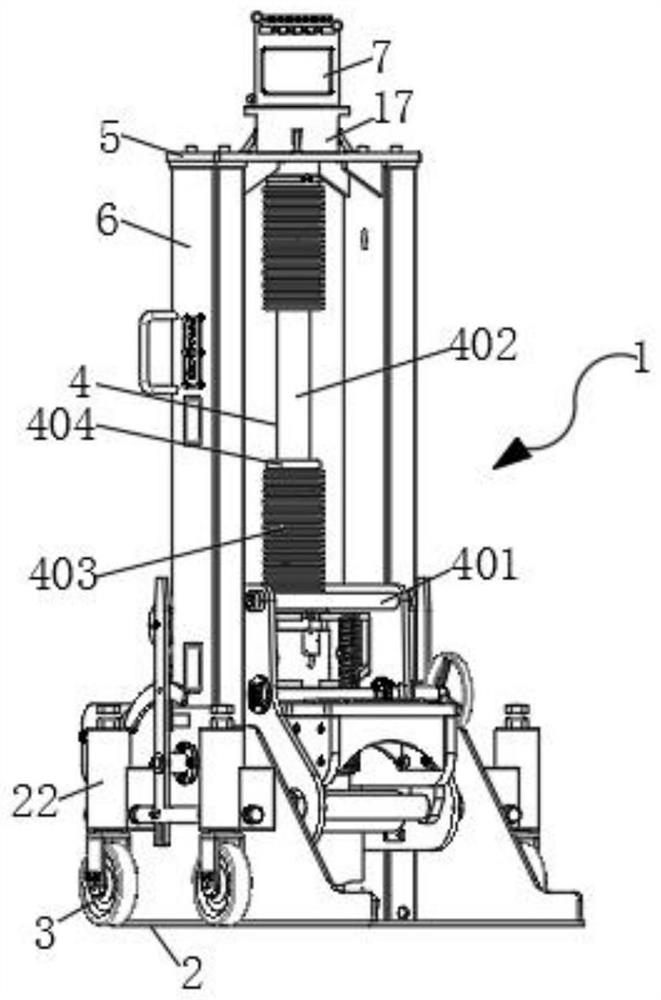

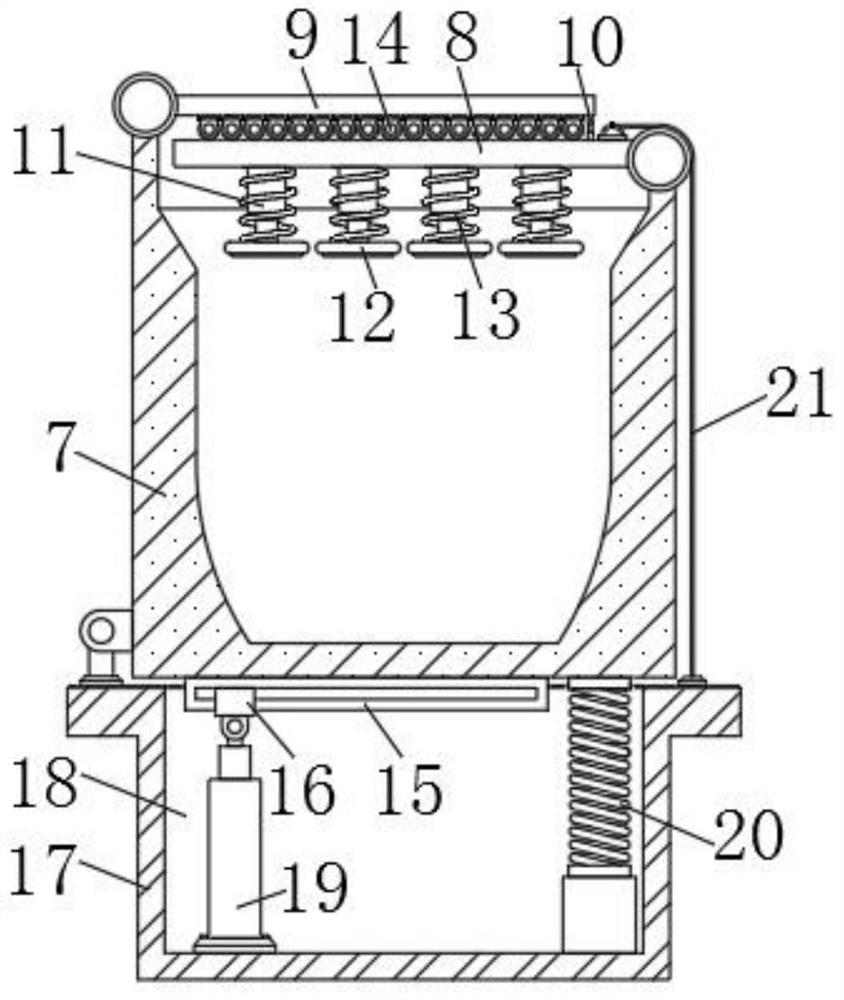

[0043] like Figure 1-2 As shown, a jacking device for steel structure grid installation includes a jacking mechanism 1, and the jacking mechanism 1 includes a base 2, rolling wheels 3, jacking parts 4, a top plate 5 and two side plates 6 , the two side plates 6 are fixedly installed on both sides of the top surface of the base 2 respectively, the lifting part 4 is arranged between the two side plates 6, and the top plate 5 is fixedly installed on the top of the two side plates 6 Between, the top surface of the top plate 5 is provided with a silo 7;

[0044] The inner wall of the silo 7 is arranged in an arc shape, and the two sides of the silo 7 are respectively hinged with a pressing plate 8 and a blanking plate 9, and the pressing block 12 at the bottom of the pressing plate 8 is under the action of the first spring 13 The grid parts in the feed bin 7 can be compressed, and the blanking roller 14 on the bottom surface of the blanking plate 9 is convenient for the grid part...

Embodiment 2

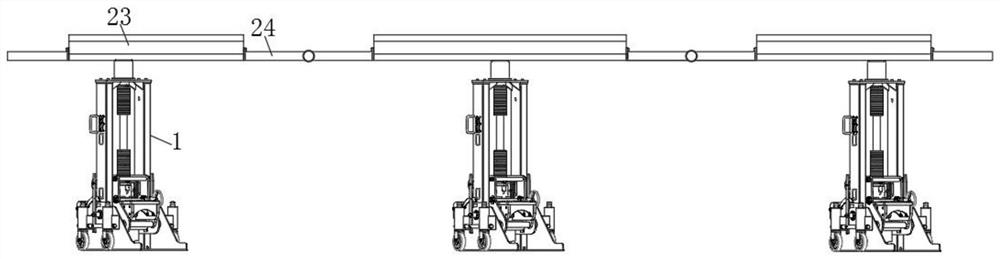

[0066] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that there are multiple jacking mechanisms 1, the bottoms of multiple jacking mechanisms 1 are located on the same horizontal line, and the output ends of the jacking cylinders 402 of multiple jacking mechanisms 1 are all A discharge chute 23 is fixedly installed, and connection plates 24 are fixedly installed on both sides of the discharge chute 23, and the adjacent ends of two adjacent connection plates 24 are hinged, and a plurality of discharge chutes 23 are formed with the connection plate 24 A material trough used to prevent the whole grid frame. Workers can install the steel structure grid frame on the flat ground, and after the installation is completed, place the grid frame as a whole inside the material tank, and simultaneously jack up the grid frame by multiple jacking devices The grid frame is transported upwards; this jacking method can lift and transport the grid frame as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com