A flushing device for safe protection of textile materials

A technology for textile materials and safety protection is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the processing of carriers of textile materials. , to achieve the effect of increasing the adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

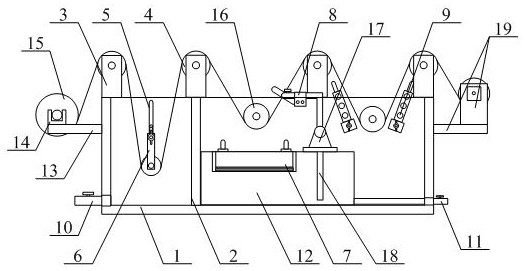

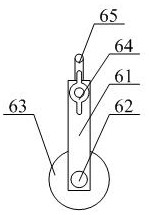

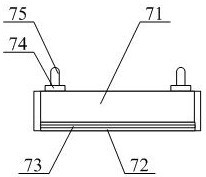

[0036] The present invention will be specifically described below in conjunction with the accompanying drawings. figure 1 and attached figure 2 As shown, a washing device for safety protection of textile materials includes a washing tank 1, a partition plate 2, a support frame 3, a guide roller 4, an adjustment hole 5, a structure 6 that can be locked and guide the soaking roller, and can filter Cleaning box structure 7, adjustable flushing pipe structure 8, rotatable drying rack structure 9, discharge pipe 10, replacement pipe 11, flushing box 12, first support plate 13, U-shaped frame 14, material roller 15, fixed roller 16 , the flushing pump 17, the suction pipe 18 and the winding device 19, the partition plate 2 is bolted to the left middle position of the inner wall of the flushing tank 1; the support frame 3 is bolted to the flushing tank 1 from left to right The upper end of the tank 1; the guide rollers 4 are respectively axially connected to the inner middle positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com