Fabricated tempered glass curtain wall

A tempered glass, prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of reduced sealing, multiple gaps in the tempered glass curtain wall, and the tempered glass curtain wall and the tempered glass curtain wall cannot be effectively adjusted and aligned. Comfort, increased aesthetics and sealing, structurally stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

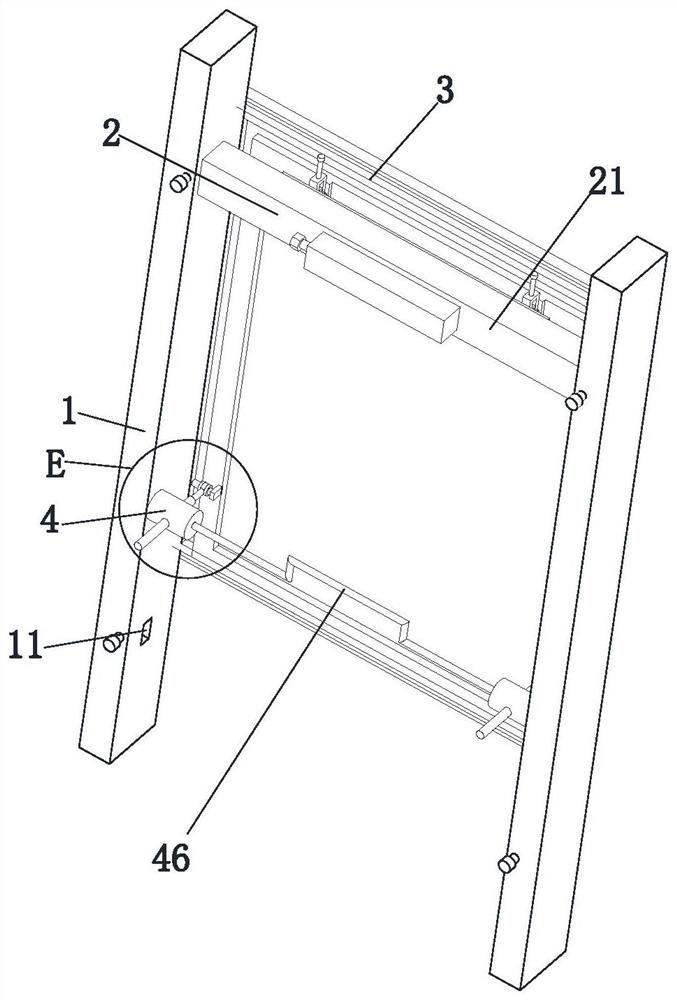

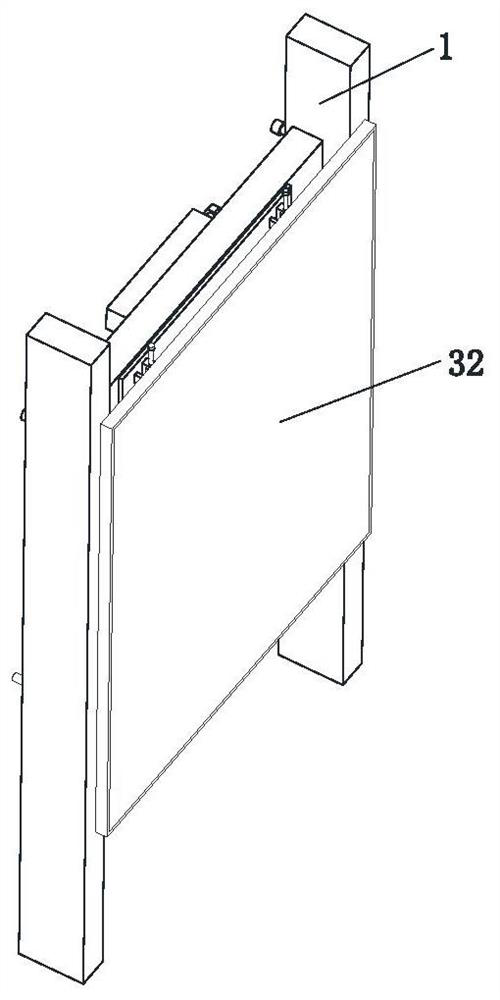

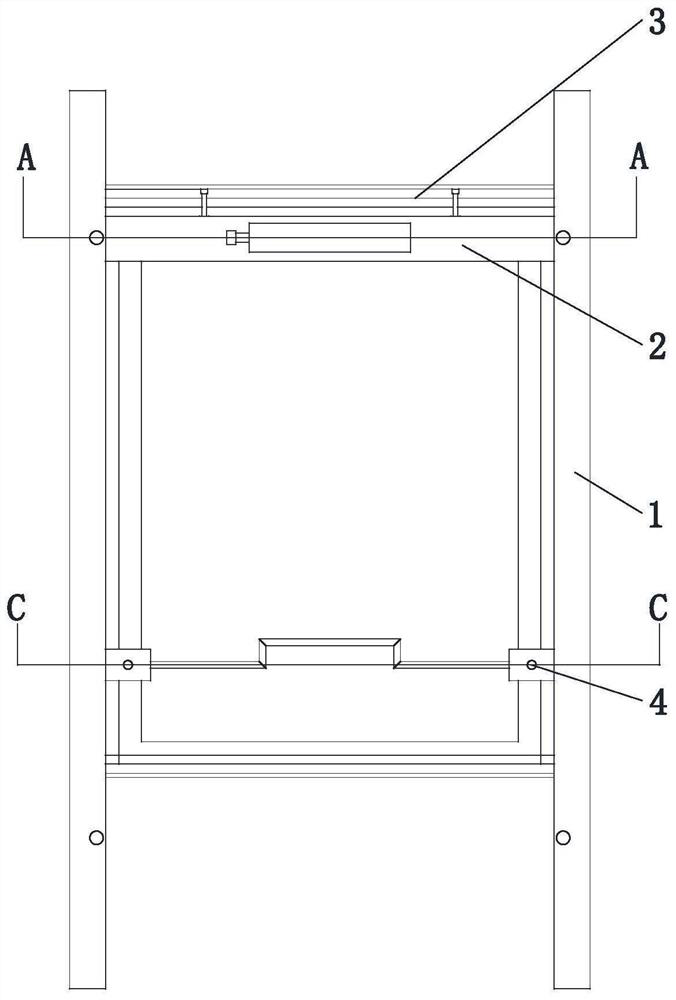

[0028]Referring to 1-9, an assembled tempered glass curtain wall, including a column 1, a beam assembly 2, a glass mounting frame 3, and an on-side wall of the column 1, and a uniform straight line is uniformly straight. The groove 11, and the column 1 is provided with the beam assembly 2, and the glass mounting frame 3 is engaged on the beam assembly 2, and the top-tensile assembly 4 is disposed on the lower side wall of the lower side of the lock tank 11. Connect to the glass installation frame 3;

[0029]The beam assembly 2 includes a cross-beam 21, a telescopic groove 22, a s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap