Double-acting sleeve rotating guide shoe

A double-action, casing technology, applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of easy insertion into the formation, stuck, irregular wellbore, etc., and achieve the effect of improving the cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

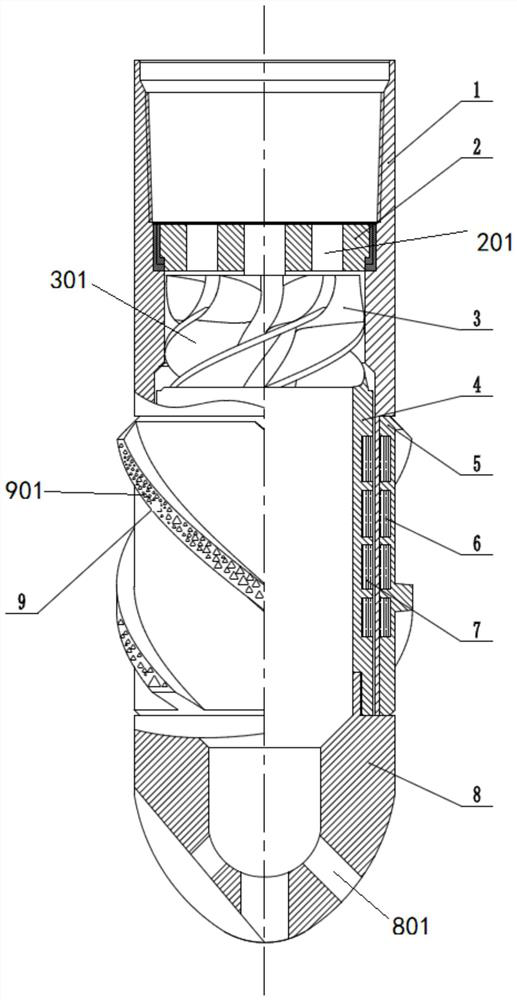

[0024] figure 1 Schematic diagram of the structure of the double-acting casing rotary guide shoe provided by the embodiment of the present invention; figure 1 As shown, a double-acting casing rotary guide shoe provided in this embodiment includes a body 1, a diverter valve plate 2, a rotor 3, a mandrel 4, an outer rotating sleeve 5, and a guide shoe head 8; the body 1, The mandrel 4 and the outer rotating sleeve 5 are both sleeve-shaped structures. The surface of the rotor 3 is provided with a number of spirally distributed rotor blades 301. The guide valve plate 2 is provided with a number of through guide holes 201. The guide The flow valve plate 2 is fixedly installed inside the body 1, the two ends of the rotor 3 are respectively fixedly connected with the flow diversion valve plate 2 and the mandrel 4, and the rotor 3 is installed downstream of the flow diversion valve plate 2 , the end of the mandrel 4 is fixedly connected to the boot 8;

[0025] The outer rotating sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com