Prediction method and device for residual life of operation assembly in lifting mechanism

A technology for running components and components, applied in computer-aided design, special data processing applications, geometric CAD, etc., can solve problems such as high cost and inability to predict the remaining life of the lifting mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] As mentioned above, regular inspections of the running components in the lifting mechanism not only require high costs, but also cause failures in the running components of the lifting mechanism between two inspections, which will still lead to unplanned shutdowns, and The inspection time is long, and it is impossible to predict the remaining life of the running components in the lifting mechanism.

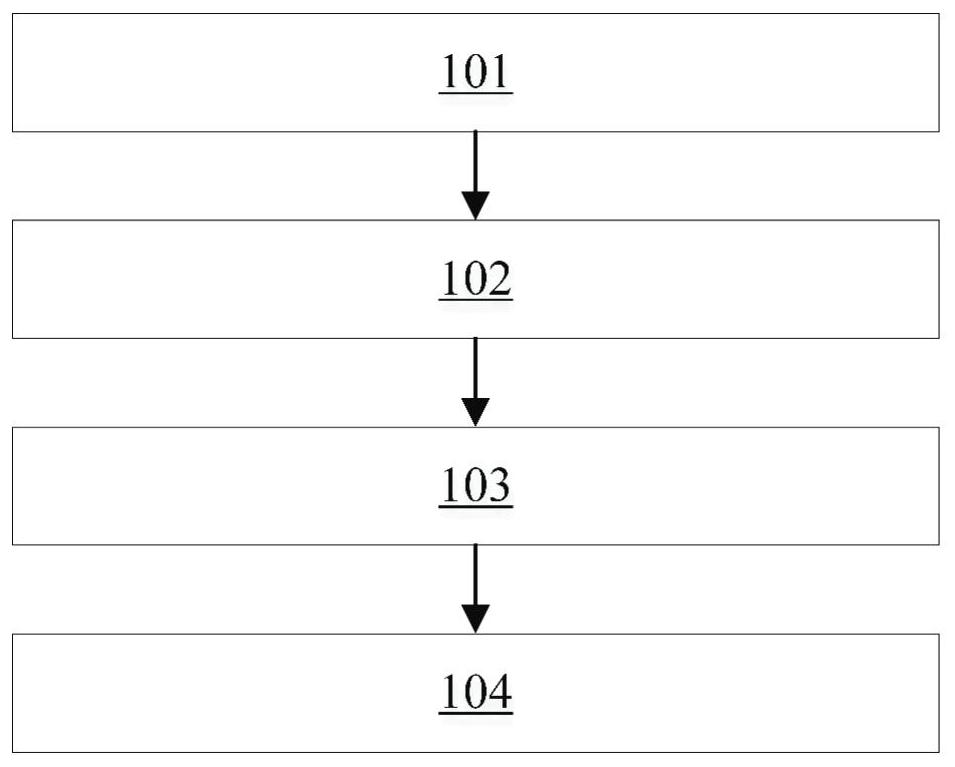

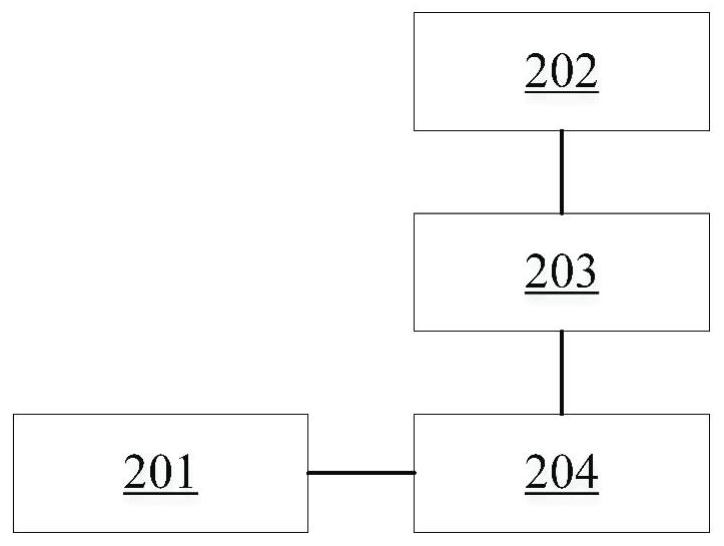

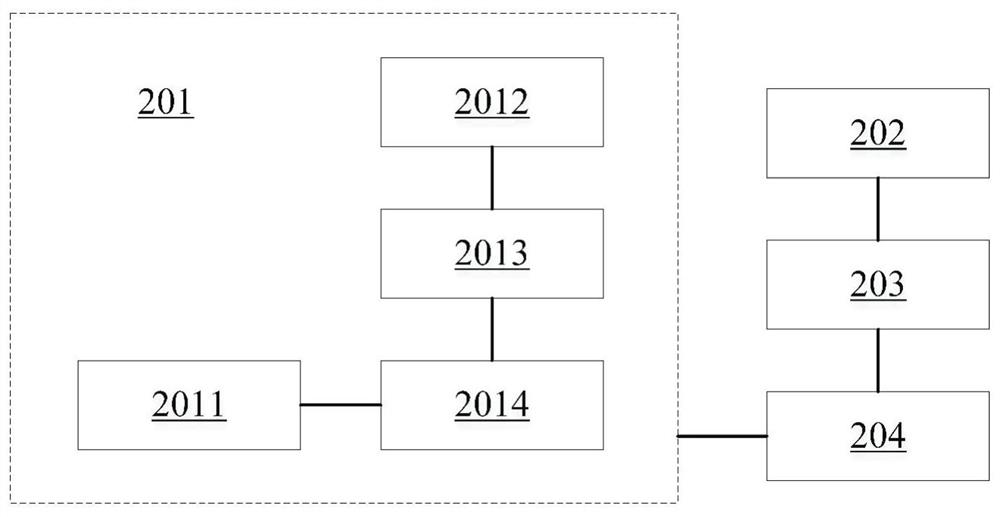

[0115] In the embodiment of the present invention, the running components in the lifting mechanism all correspond to the remaining life calculation values, and the influencing factors will affect the remaining life of the running components. Each running component has at least one influencing factor, and each influencing factor can be passed Real-time monitoring obtains its monitoring value, and by pre-constructing the corresponding relationship between the impact factor, monitoring value range, and life coefficient, the life coefficient corresponding to each impact factor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com