A Pipeline Remaining Life Prediction Method Based on Inverse Gaussian Process and em-pf

An EM-PF, life prediction technology, applied in instrumentation, design optimization/simulation, calculation, etc., can solve problems such as failure to accurately predict the remaining life of oil and gas pipelines, and difficulty in obtaining reliability failure time data of oil and gas pipelines in a short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

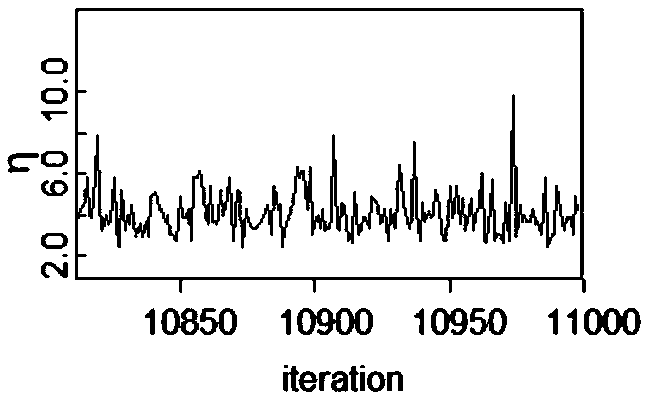

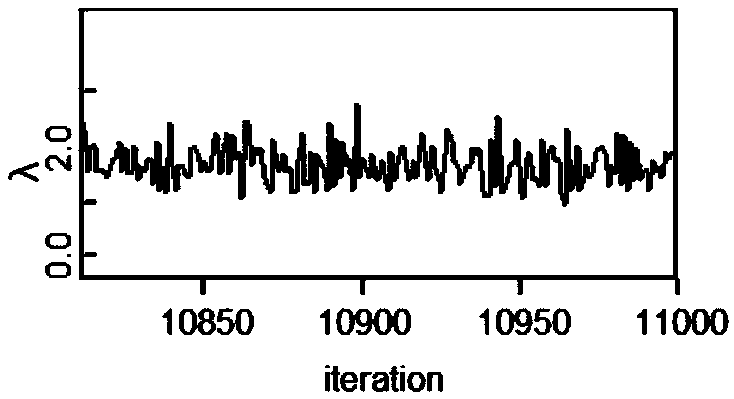

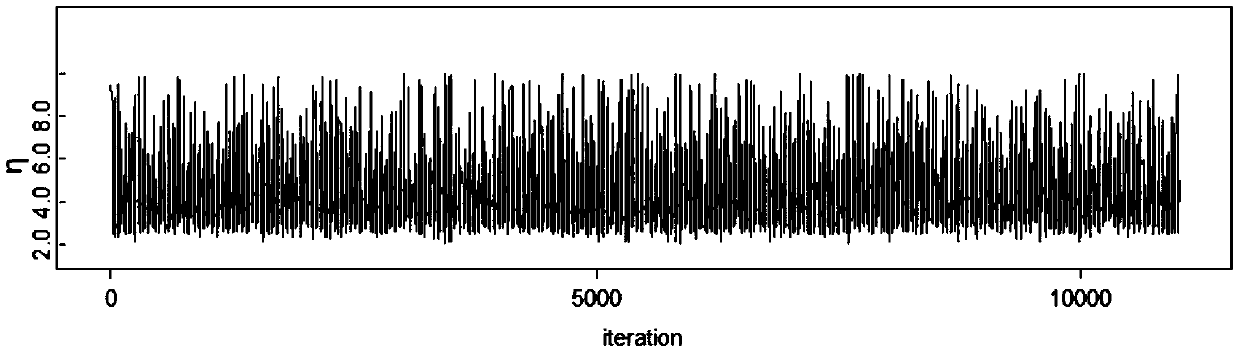

[0036] Referring to Fig. 1, the pipeline remaining life prediction method based on inverse Gaussian process and EM-PF according to the present invention includes the following steps: obtaining corrosion data of oil and gas pipelines, and then using stochastic process-inverse Gaussian process to describe oil and gas according to the corrosion data of oil and gas pipelines For the corrosion degradation process of the pipeline, the state equation and observation equation of the oil and gas pipeline state space model are established, and then the inverse Gauss-state corrosion degradation model is established according to the state equation and observation equation of the oil and gas pipeline state space model, and then the inverse Gauss-state corrosion degradation model is established according to the inverse Gauss-state corrosion degradation model Predict remaining life of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com