Mistake-proof heavy truck battery and electric plug butt joint system

An electric plug and battery technology, applied in the field of machinery, can solve problems such as damage to the electric plug interface, low degree of intelligence, and inability to monitor whether the connection is successful or not, so as to ensure the effect of handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

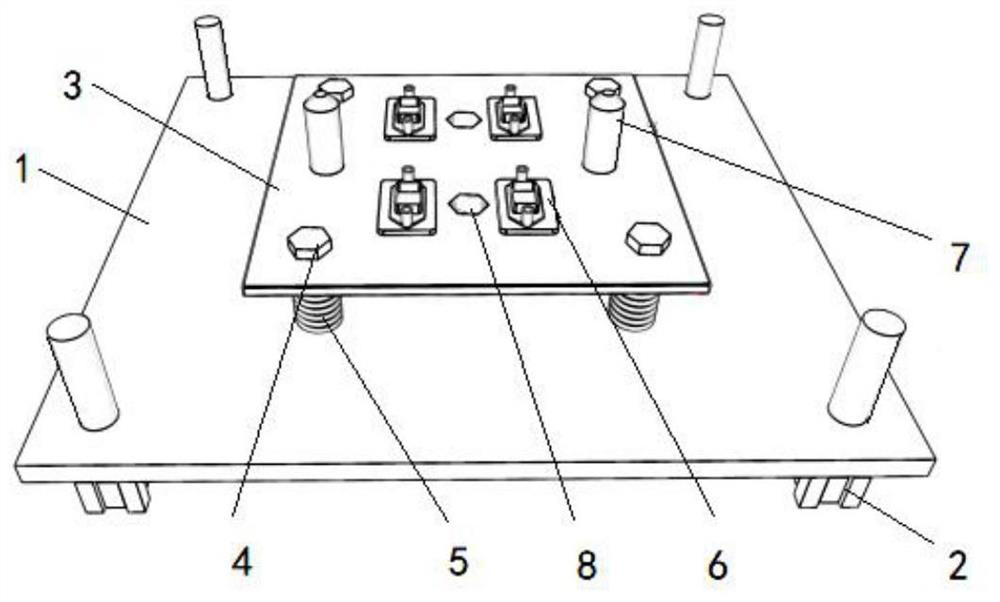

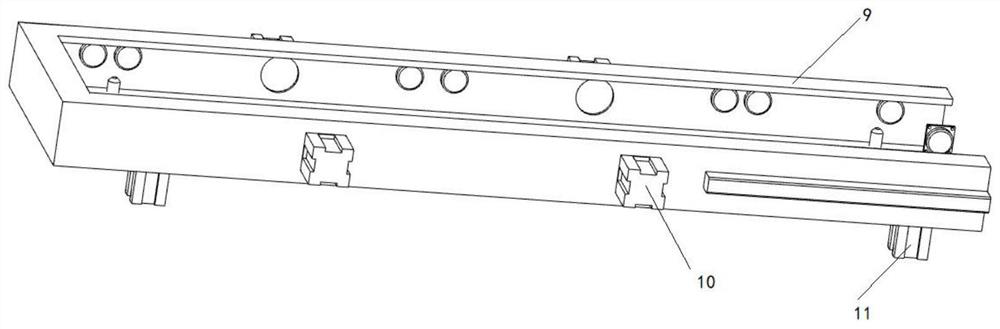

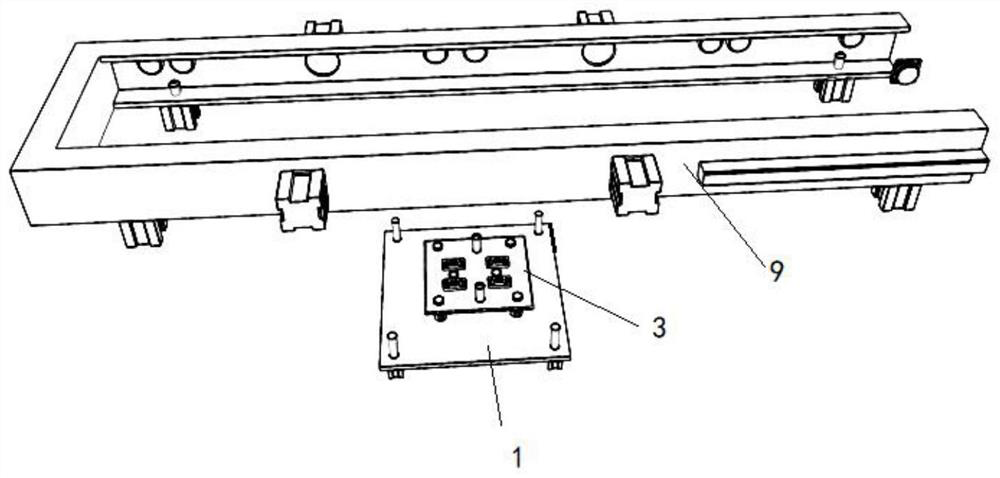

[0045] see Figure 1 to Figure 3 , specific embodiment 1: a docking system for an error-proof heavy-duty battery and an electric plug, including a battery bracket 9 that is fixed with a heavy-duty battery, and also includes a support platform for installing an electric plug 6, the electric plug 6 and the heavy-duty battery The sockets at the bottom match; the supporting platform includes a lifting platform 1 and a lifting mechanism 2 for driving the lifting platform 1 to lift, and the lifting mechanism 2 is connected with the lifting platform 1; the supporting platform also includes a floating platform 3, and the four corners of the floating platform 3 The part is slidingly connected with the bolt 4, and the bolt 4 is fixedly connected with the lifting platform 1, and the outer periphery of the bolt 4 is provided with a spring 5, and the spring clip is arranged between the floating platform 3 and the lifting platform 1; the floating platform 3 is equipped with an electric plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com