Casing pressure transit time method material level instrument

A technology of transit time and material level, which is applied in directions such as buoy liquid level indicators, and can solve problems such as measurement data deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

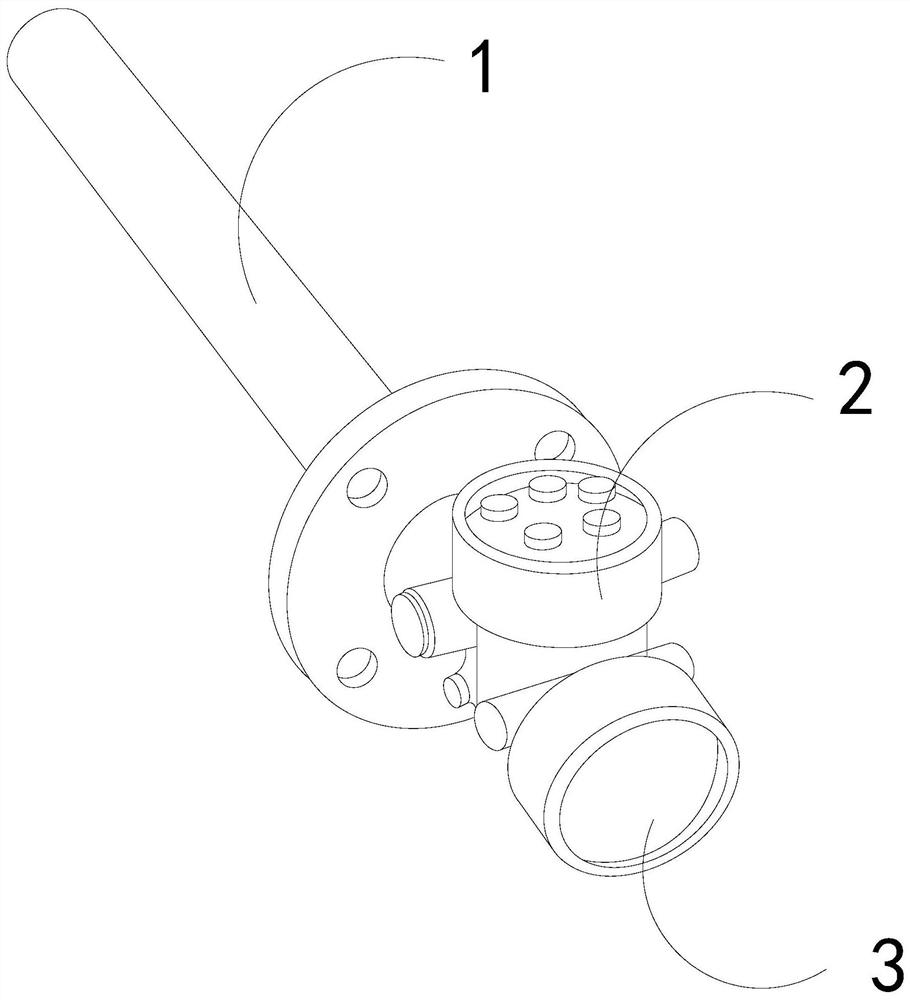

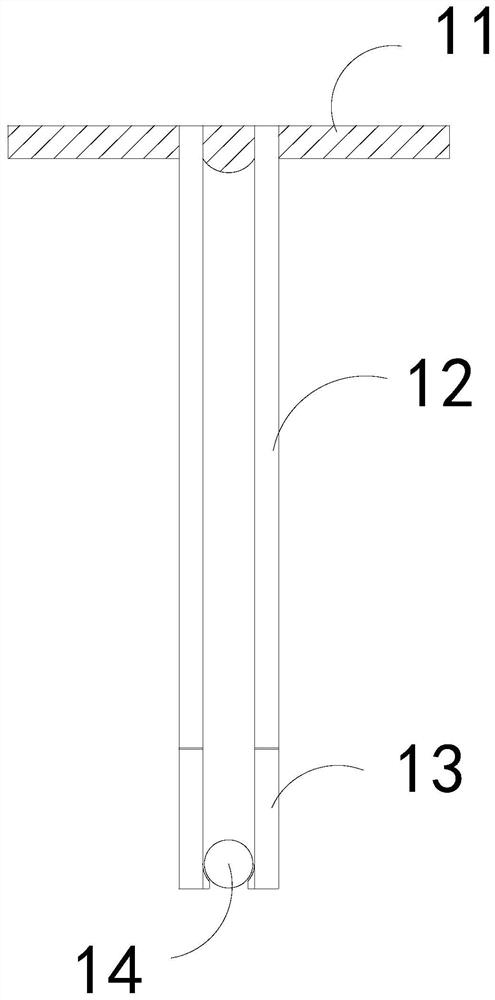

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a casing pressure transit time method material level instrument, its structure includes a measuring rod 1, a handle 2, and a display screen 3, the display screen 3 is embedded in the front end of the handle 2, and the measuring rod 1 is installed on The rear end position of the handle 2; the measuring rod 1 includes an engaging plate 11, a rod body 12, an outer row mechanism 13, and a floating ball 14, and the rod body 12 is embedded in the inner center position of the connecting plate 11, and the outer row mechanism 13 and The rod body 12 is an integrated structure, and the floating ball 14 is installed at the inner position of the rod body 12 and the outer row mechanism 13 .

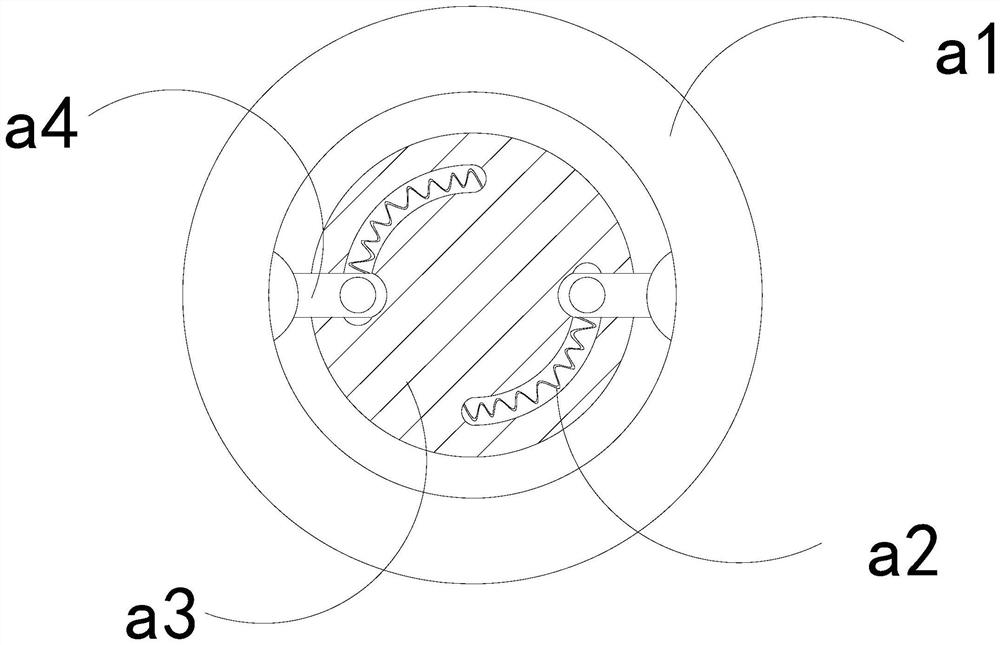

[0028] Wherein, the floating ball 14 includes a stressed ring a1, an elastic strip a2, a fixed block a3, and a coupling rod a4, the stressed ring a1 is movably engaged with the fixed block a3 through the cou...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the outer discharge mechanism 13 includes a frame c1, a discharge block c2, a squeeze ball c3, and a booster bar c4. The discharge block c2 is embedded in the bottom position of the inner wall of the frame c1, and the squeeze ball c3 passes The booster bar c4 is connected to the upper end of the inner wall of the frame c1. There are two extrusion balls c3, which are evenly distributed symmetrically inside the frame c1. Duckweed presses down.

[0036] Wherein, the discharge block c2 includes a stressed roller c21, a plate c22, a direction limiting block c23, and a connecting plate c24. The stressed roller c21 is movably engaged with the connecting plate c24. In the middle position of c21, the connecting plate c24 is embedded and connected with the plate c22, and the water can generate a downward thrust on the force-bearing roller c21, which can make the force-bearing roller c21 rotate clockwise, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com