Free forging process of thin-wall special-shaped step cylinder piece

A free and crafty technology, applied in the direction of metal processing equipment, other household appliances, household appliances, etc., can solve the problems of complex shape, size, changeable specifications, and inability to meet the forging requirements of large-scale thin-walled special-shaped stepped tube parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

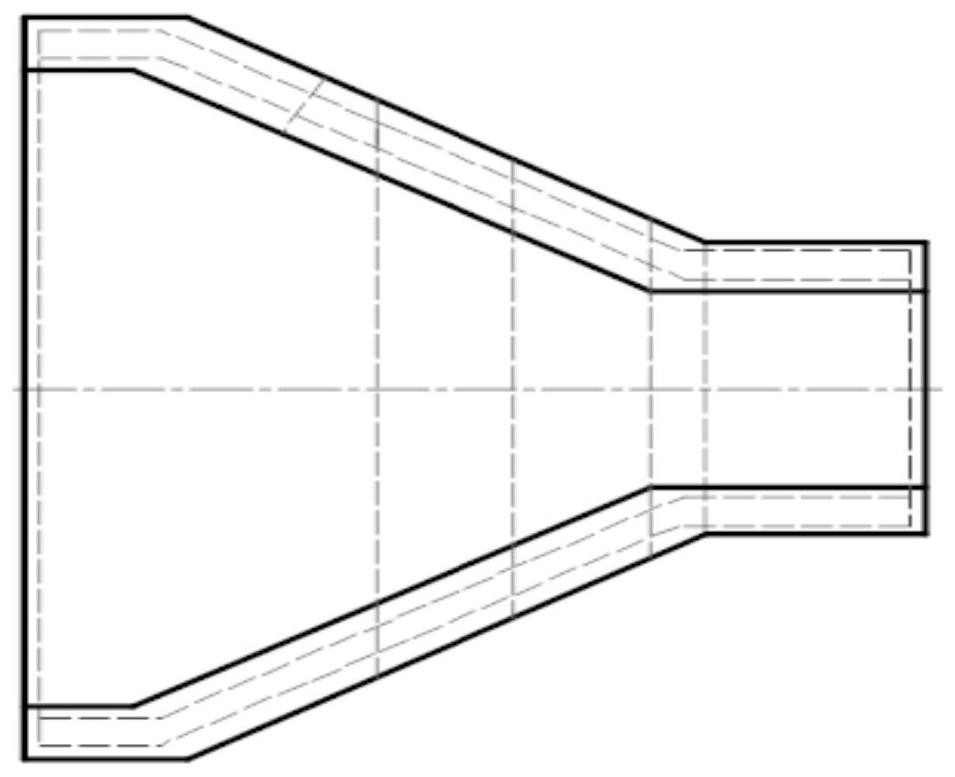

[0033] Production of a CrXNiY steel grade (0Cr13Ni7Mo), the specifications are: total length 1640mm, large table size small table size The transition from the large platform to the small platform is smooth, and the length of the transition section is 940mm (specifically as figure 1 shown). The specific forging process is as follows:

[0034] The first step: out of the furnace, the whole ingot upsetting H≤1100mm, pulled out to Return to the furnace to keep warm for 1 to 5 hours;

[0035] The second step: out of the oven, pull out to grow Cutting: Return to the furnace to keep warm for 1~5h;

[0036] The third step: out of the furnace, upsetting H≤600mm Punch punching, control the thickness of the punch material ≤ 50mm, return to the furnace to cool down to 1200±10°C, and keep warm for 1-5h;

[0037] The fourth step: out of the oven, expand the inner hole as a whole Return to the furnace and keep warm for 1 to 3 hours;

[0038]The fifth step: out of the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com