Hammering and nailing device for bass drum head for musical instrument processing

A large drum and drum skin technology, which is applied in the direction of manufacturing tools, nailing tools, U-shaped nailing tools, etc., can solve the problems of labor and hand hammering, achieve good adsorption, prevent hand hammering, and facilitate hammering work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

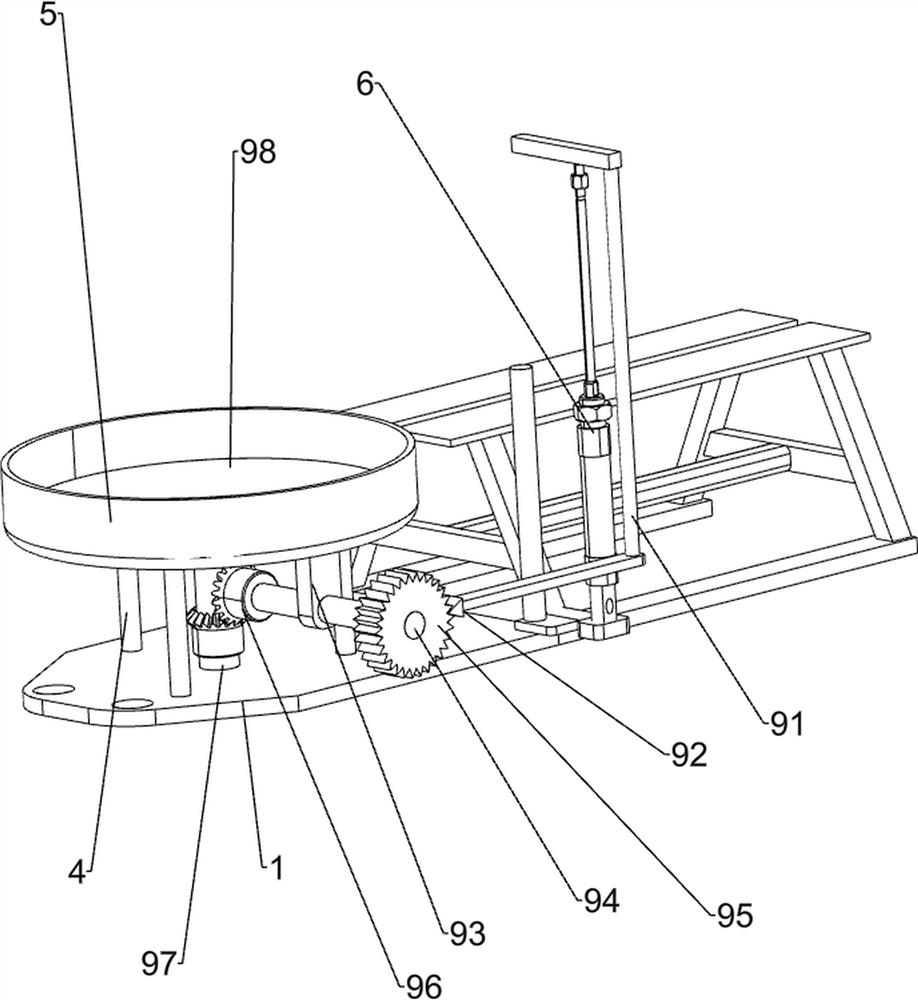

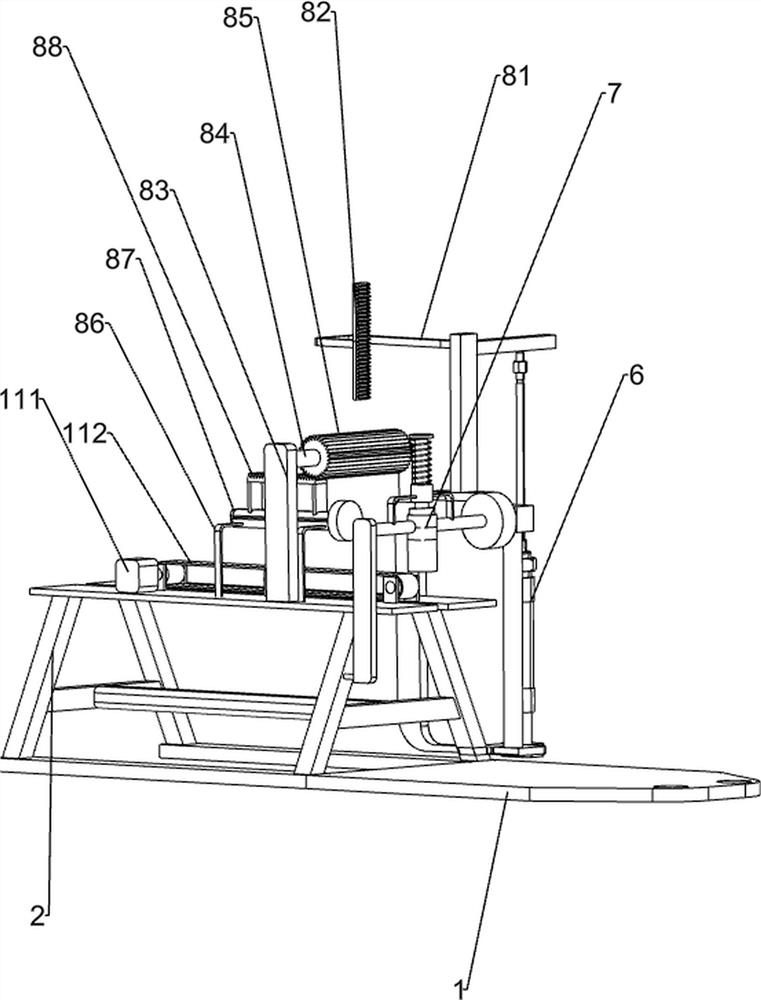

[0026] A drum skin hammering device for musical instrument processing, such as Figure 1-3 As shown, it includes a base 1, a support frame 2, a vertical rod 4, a positioning bucket 5, a driving mechanism 6, a rotating mechanism 7 and a pushing mechanism 8, the right side of the top of the base 1 is connected with the support frame 2, and the left part of the base 1 has two A screw hole 3, a plurality of vertical rods 4 are connected on the left side of the top of the base 1, a positioning bucket 5 is connected between the tops of the plurality of vertical rods 4, a driving mechanism 6 is installed on the support frame 2, and a rotating shaft is connected on the driving mechanism 6. Mechanism 7, a pushing mechanism 8 is installed on the support frame 2.

[0027] The driving mechanism 6 includes a support plate 61, a cylinder 62, a support column 63, a first rotating rod 64, an L-shaped connecting rod 65, a contact plate 66 and a torsion spring 67, and the lower part of the left...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 and Figure 4 As shown, also includes transposition mechanism 9, and transposition mechanism 9 comprises moving rod 91, driving tooth 92, connecting plate 93, the 3rd rotating rod 94, one-way gear 95, bevel gear assembly 96, the 4th rotating rod 97 With rotating disk 98, L-shaped connecting rod 65 front portion is connected with moving rod 91, and the left end of moving rod 91 is connected with driving tooth 92, and the front side of positioning bucket 5 bottom is connected with connecting plate 93, and the connecting plate 93 is connected with the third rotation. Rod 94, the front side of the third rotating rod 94 is connected with a one-way gear 95, the one-way gear 95 meshes with the drive tooth 92, and the left side of the base 1 top is connected with a fourth rotating rod 97 in a rotational manner, and the top of the fourth rotating rod 97 wears Through the positioning barrel 5 , a turntable 98 is connected to the top of...

Embodiment 3

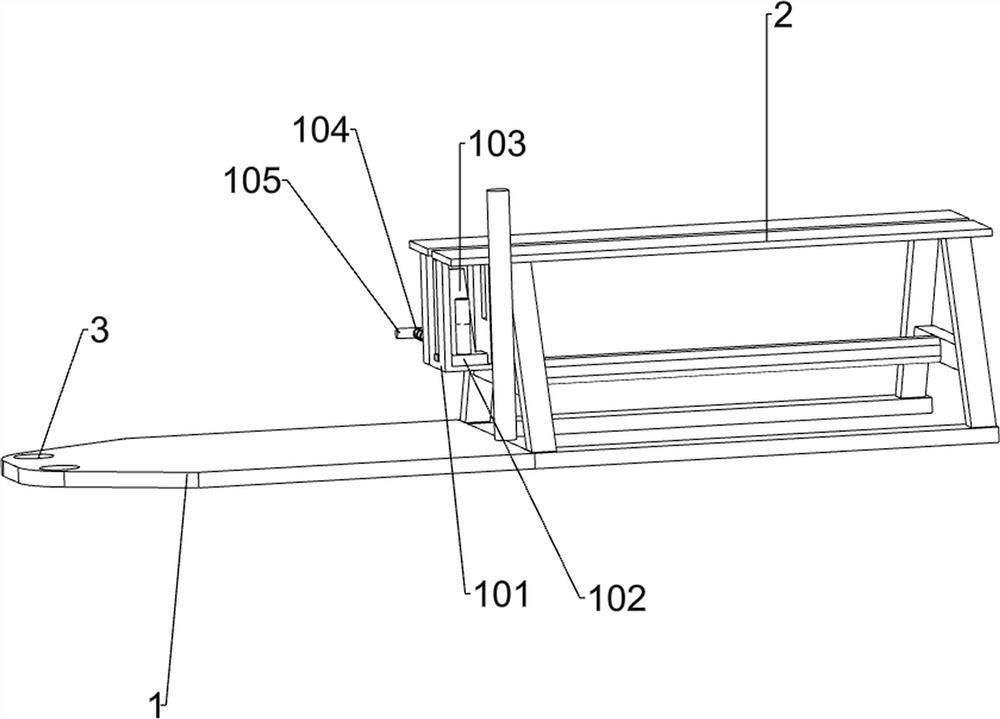

[0035] On the basis of Example 2, such as figure 1 and Figure 5 As shown, also includes lifting mechanism 10, and lifting mechanism 10 includes U-shaped frame 101, locator 102, trapezoidal block 103, second spring 104 and handle 105, and support frame 2 upper left side is connected with U-shaped frame 101, U-shaped A locator 102 is slidably connected to the front side of the frame 101, a trapezoidal block 103 is slidably connected to the rear of the U-shaped frame 101, and the trapezoidal block 103 contacts and cooperates with the locator 102, and a handle is slidably connected to the rear of the U-shaped frame 101 105 , the handle 105 is fixedly connected to the trapezoidal block 103 , and the second spring 104 is connected between the handle 105 and the U-shaped frame 101 .

[0036] The handle 105 can be pushed forward to move the trapezoidal block 103 forward, and the second spring 104 is compressed thereupon. The forward movement of the trapezoidal block 103 can make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com