Four-arm-linkage locking mechanism

A locking mechanism and linkage technology, which is applied in the field of production equipment for refrigerated vehicle insulation composite panels, can solve the problems of low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

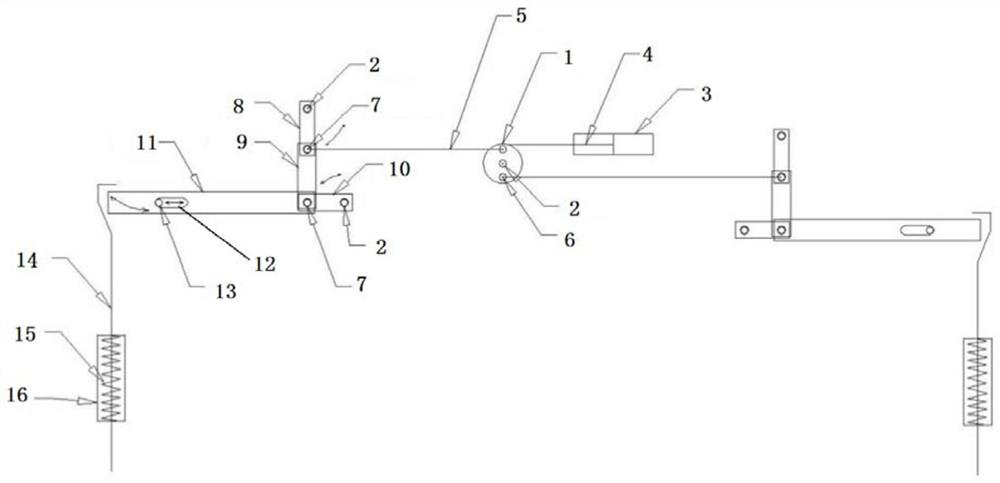

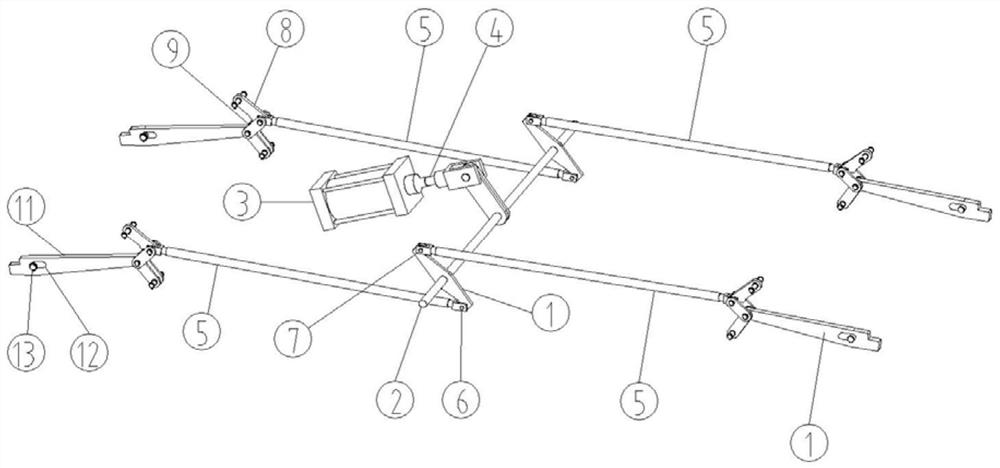

[0023] A four-arm linkage locking mechanism, including a turntable, the turntable is fixed to the upper mold through a fixed pin, and a cylinder is installed beside the turntable, the piston rod of the cylinder is connected with the turntable, and the turntable is symmetrically connected with a center of the turntable. For connecting rod five arranged horizontally, connecting rod five is connected on the rotating disk through a connecting pin, and the other end of connecting rod five is connected with connecting rod one and connecting rod two arranged in the vertical direction through a movable connecting pin, and the other end of connecting rod one One end is connected to the upper mold through a fixed pin, the other end of the connecting rod two is connected to the horizontally arranged connecting rod three and four through a movable connecting pin, the other end of the connecting rod three is connected to the upper die through a fixed pin, and the connecting rod four is A sl...

Embodiment 2

[0025] On the basis of Embodiment 1, the cylinder is controlled by a three-position five-way valve, and the three-position five-way valve is electrically connected to a master control PLC controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com