Battery thermal management control method and related device

A battery thermal management and control method technology, applied in the field of power batteries, can solve the problems of difficult to control a reasonable range of battery temperature rise, compressing the available power of the battery, weak heat dissipation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

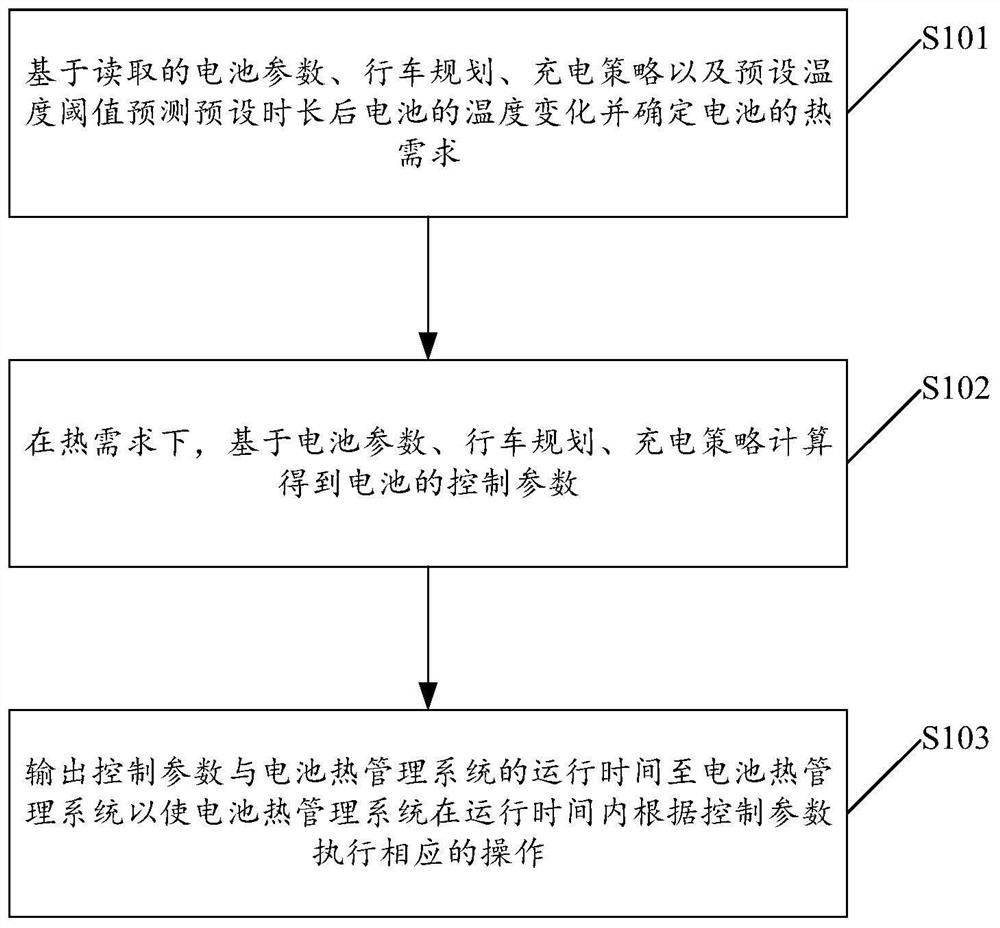

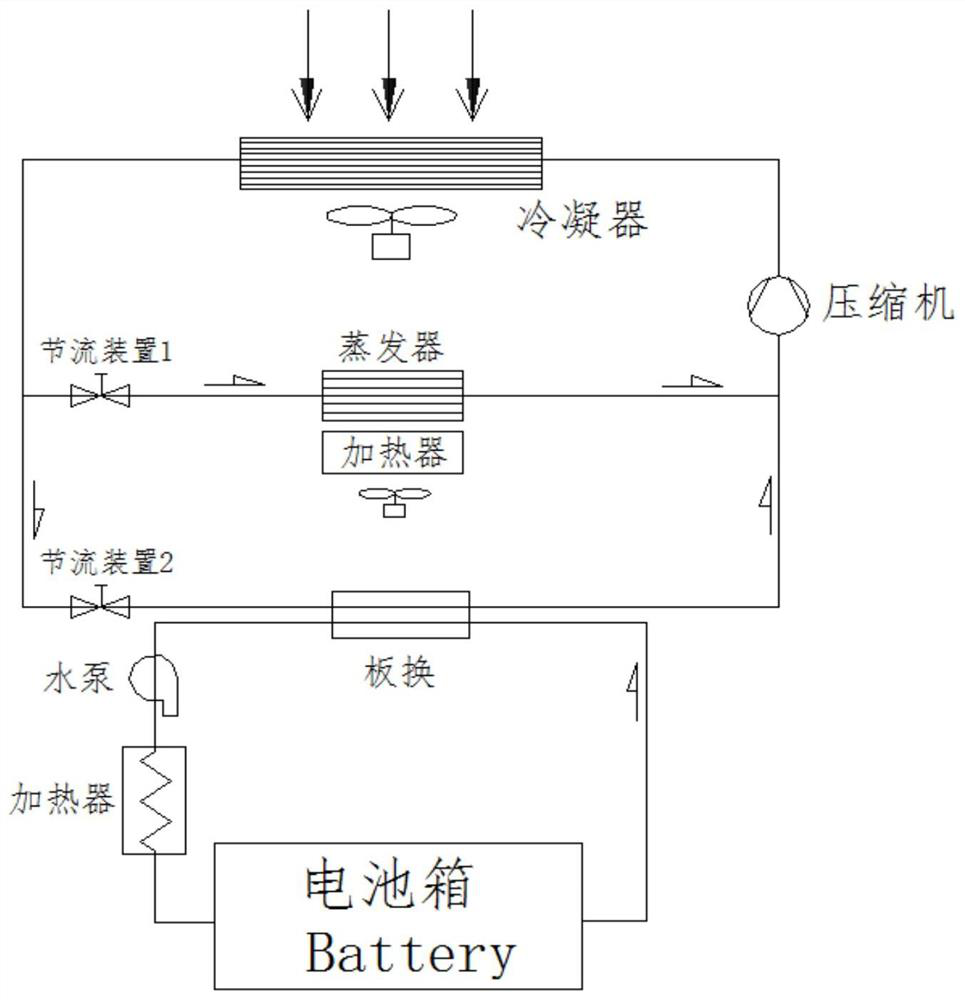

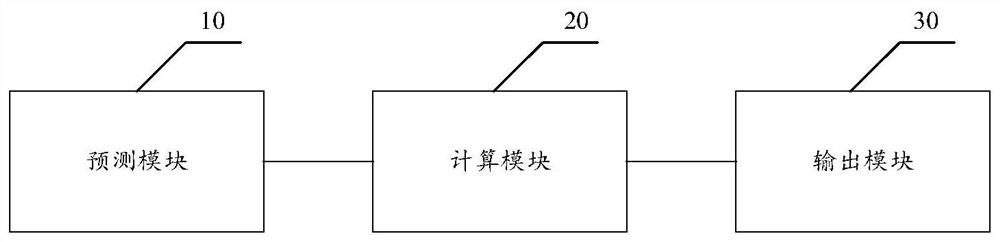

Method used

Image

Examples

Embodiment Construction

[0057] The core of this application is to provide a control method for battery thermal management, which can effectively reduce the probability of excessive battery temperature fluctuations, improve the control accuracy of battery temperature, and reduce the energy consumption of thermal management; another core of this application is to provide a A battery thermal management control device, equipment, and computer-readable storage medium capable of solving the above-mentioned technical problems.

[0058] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, not all of them. Based on the embodiments in this application, all other...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap