A kind of iron pipe handling equipment for building construction

A technology for building construction and handling equipment, applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of inconvenient structure conversion, insufficient clamping structure fixation, and application of pressure, so as to increase functionality and use transportation Convenience, increased protective measures and support assistance, less friction and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

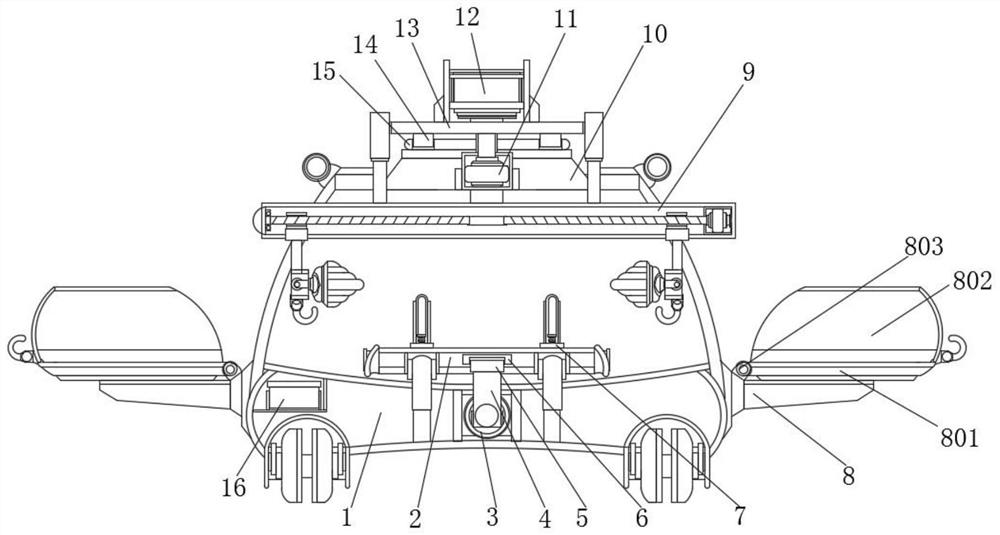

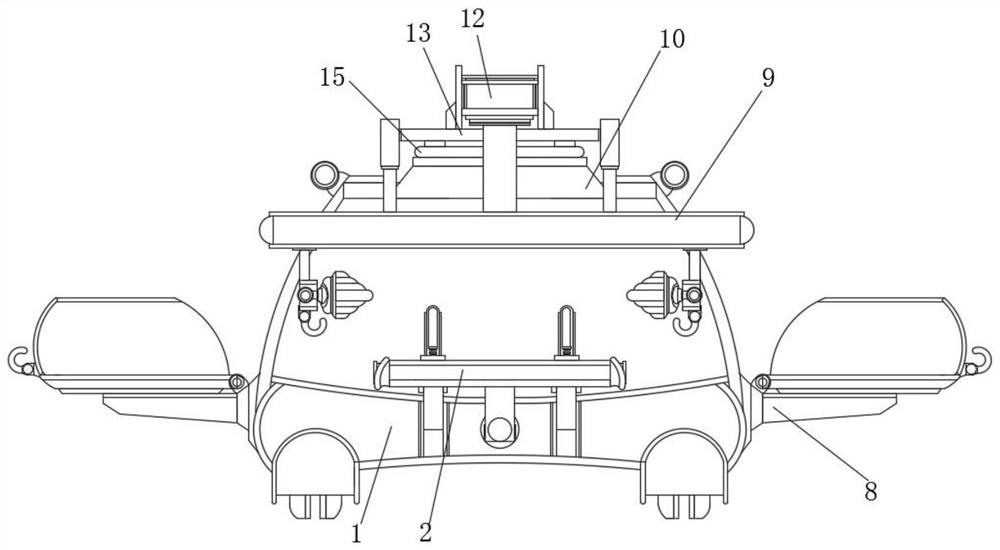

[0033] Example 1, as Figure 1-4 As shown in the figure, when only large iron pipes are clamped and transported, the multi-layer sleeve 906 can be used for progressive installation and cooperation of different sizes. The outer side of the multi-layer sleeve 906 is provided with positioning rings, which are suitable for different types of large iron pipes. , the placement plate 801 can be folded by the cooperation of the hinge shaft 803, so that the placement plate 801 and the baffle plate 802 can be inserted into the outer walls on both sides of the vehicle body 1, and at the same time, the hooks and the hanging rings can be fixed with each other, which can reduce the size of the device on both sides. The volume makes the movement more convenient and flexible, and increases the functionality and flexibility of the device.

Embodiment 2

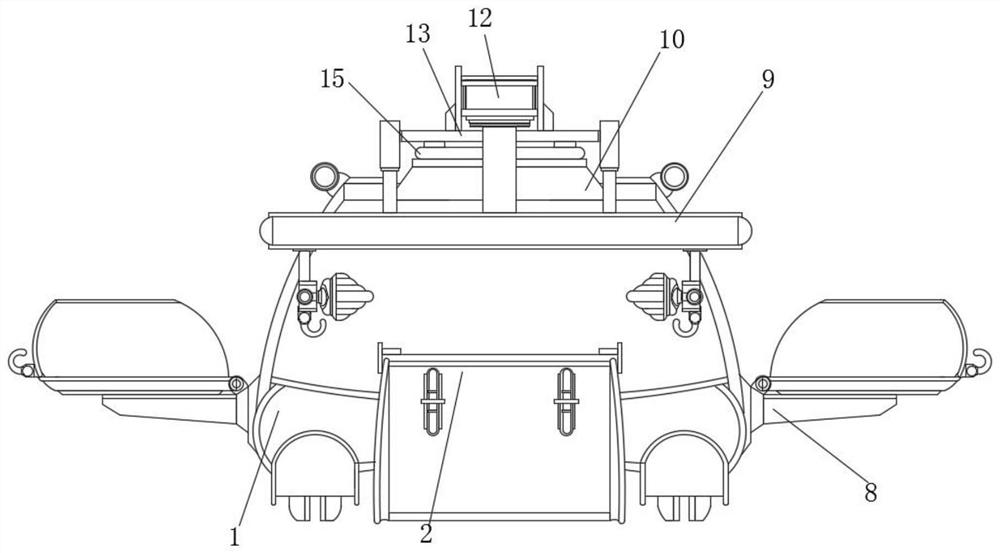

[0034] Example 2, as Figure 5-6 As shown, after the multi-layer sleeve column 906 is clamped and fixed to the large iron pipe, the hinge block 18 and the hinge plate 4 and the slider A5 can be driven by the activation of the electric push rod A3 to support the movable plate 2, and use The slider A5 makes the movable plate 2 fold and fit with the ground under the sliding cooperation of the sliding rail A6. In this way, when the movable plate 2 is attached to the ground, the iron pipe has an auxiliary buffer point when it is placed on the ground. , reduce the pressure damage of the iron pipe when it is placed again, and increase the protection function of the device to the iron pipe. When the movable plate 2 is lifted to a straight face state, a fixed auxiliary placement point is formed, and the clamped iron pipe can be placed in the electric power. The push rod B12 moves back and forth and presses into the hinge seat 706. When the hinge seat 706 drives the spring 705 to press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com