Alternating current dual-control and high-voltage matrix frequency-conversion electronic control system of hoisting machine

An electric control system and hoist technology, applied in the direction of elevators, transportation and packaging, etc., can solve problems such as insecurity and difficulty in ensuring long-term operation of frequency converters, and achieve the effects of small footprint, easy installation, and simple operation and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

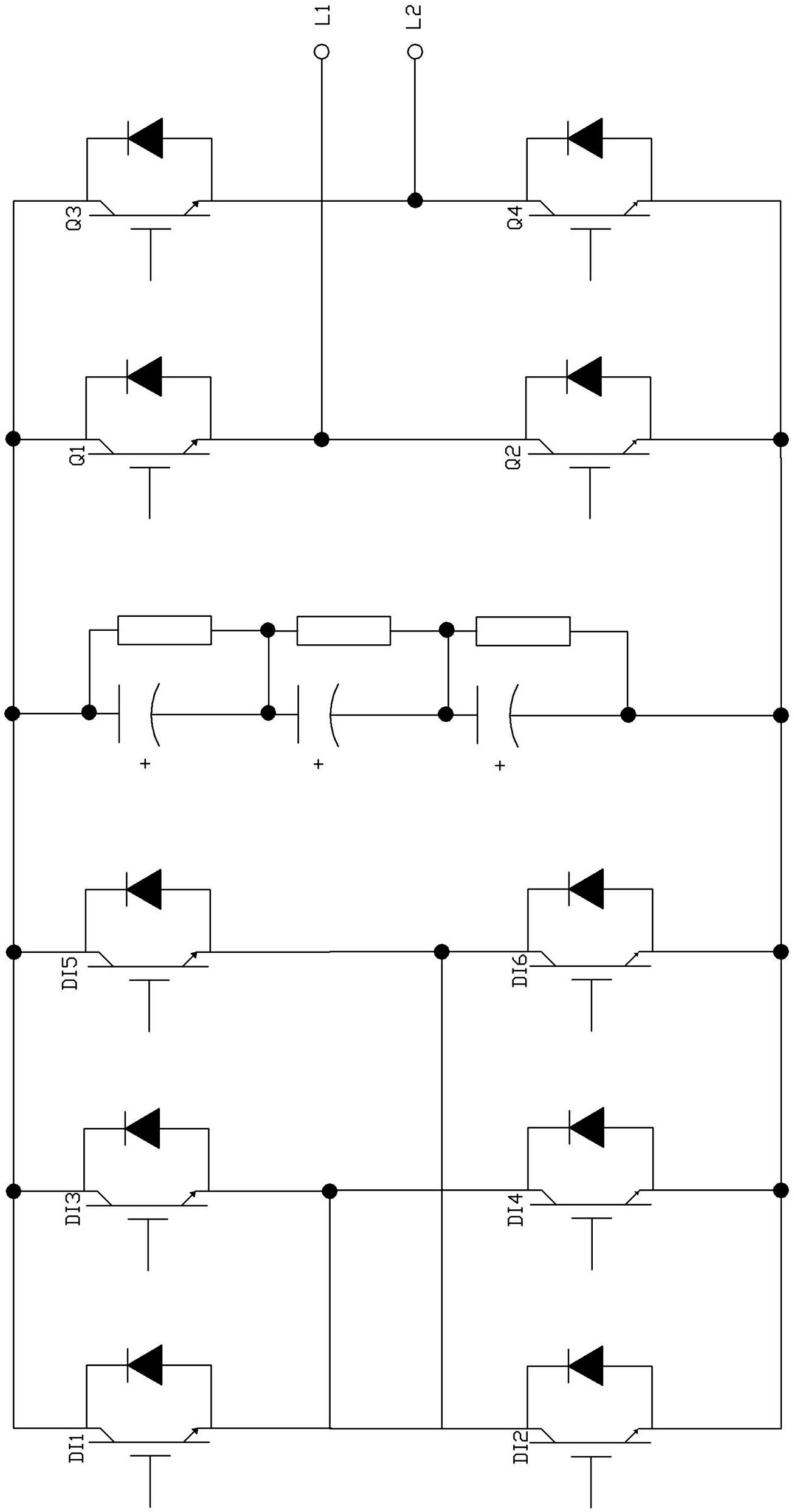

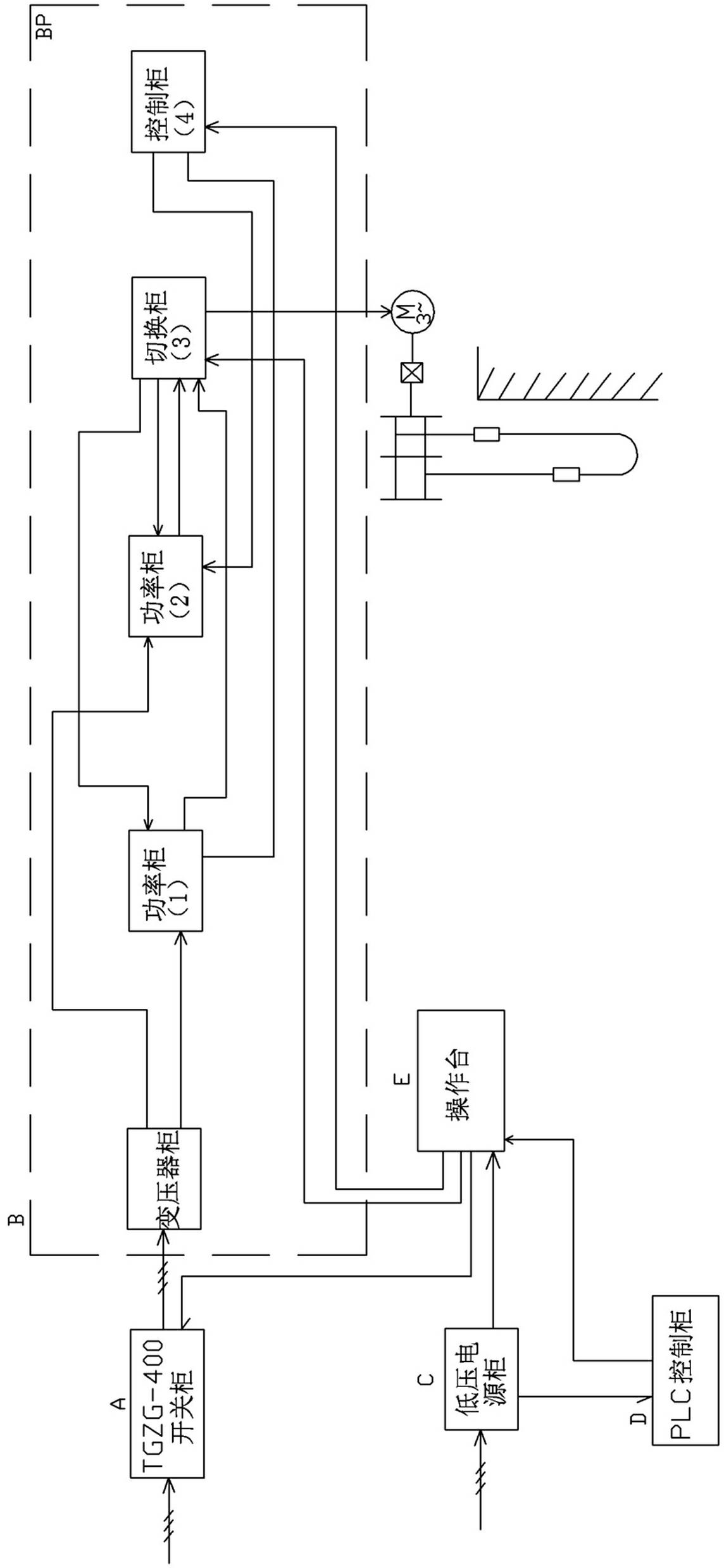

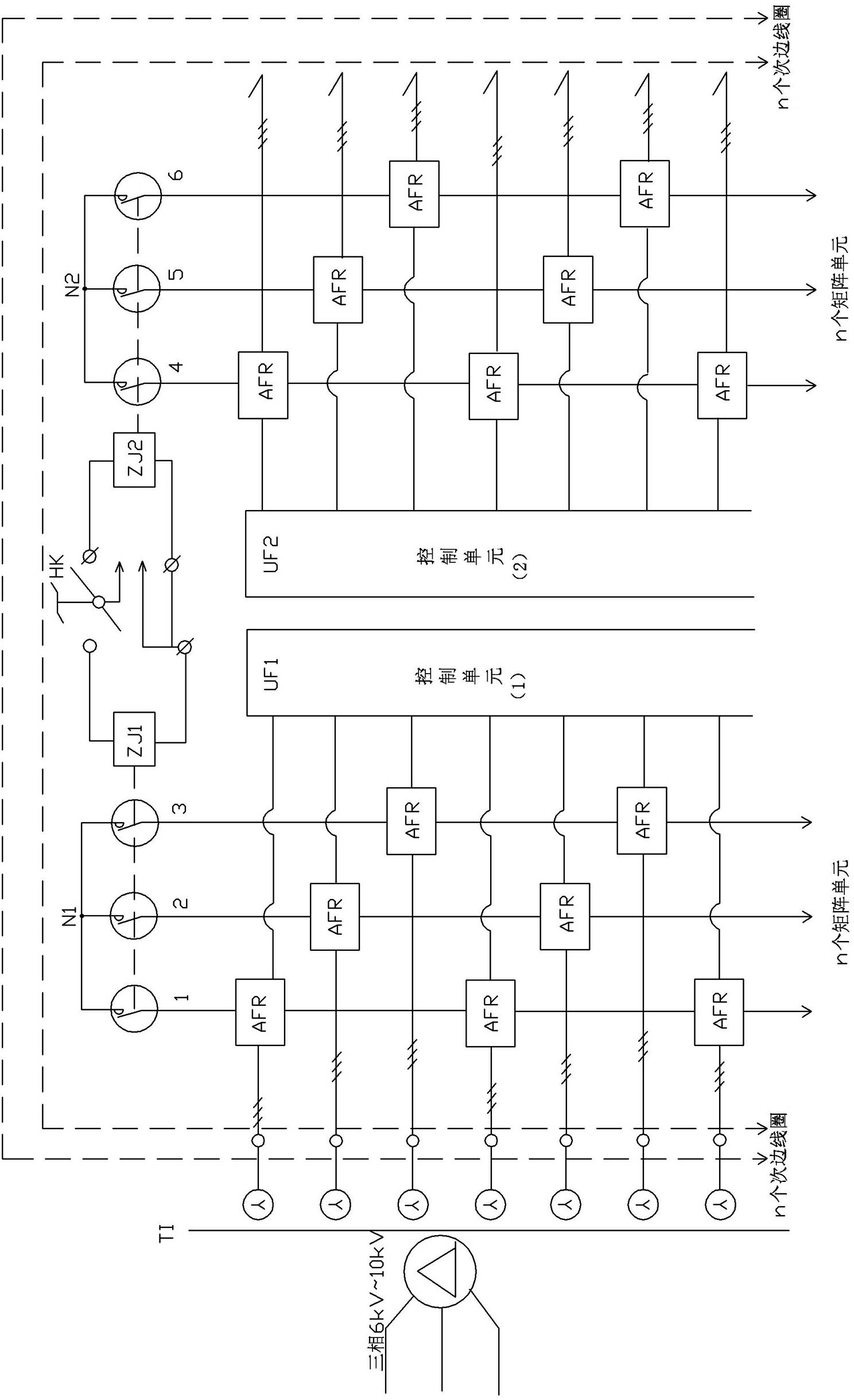

[0024] Embodiment one: see Figure 2 to Figure 7 , the mine hoist AC dual-control high-voltage matrix frequency conversion electric control system of the present invention see figure 2 , TGZG-400 high-voltage vacuum switchgear A, it has the protection requirements of the electric control system of the hoist, and meets the dual power supply incoming lines stipulated in the coal mine safety regulations. The switchgear provides the three-phase power supply to the high-voltage matrix inverter B, which is supplied to the matrix power cabinet 1 and the matrix power cabinet 2 through the transformer cabinet. Two sets of PWM control systems are installed in one control cabinet to facilitate dual-control power conversion. See image 3 , the power output is connected to the motor through the switching cabinet. See Figure 4 , the three-phase 6kv or 10kv high-voltage power supply enters the matrix variable frequency transformer cabinet TI through the vacuum switch cabinet. According t...

Embodiment 2

[0025] Embodiment two: see figure 2In this embodiment, the hoist AC dual-control high-voltage matrix frequency conversion electronic control system includes a high-voltage vacuum switch cabinet A, a high-voltage matrix frequency converter cabinet B, and an operating console E. The high-voltage matrix frequency converter cabinet B includes a transformer cabinet, two Power cabinets 1, 2, and a switching cabinet 3 and a control cabinet 4, the high-voltage vacuum switch cabinet A provides three-phase power supply to the power cabinet 1 and the power cabinet 2 through the transformer cabinet, and the control cabinet 4 is installed There are two sets of PWM control systems, which respectively control the connection between power cabinet 1 and power cabinet 2, the control connection between switching cabinet 3 and power cabinet 1 and power cabinet 2, the control connection between console E and switching cabinet 3, and the power output terminals of the two power cabinets The motors ...

Embodiment 3

[0026] Embodiment three: see Figure 2 ~ Figure 4 In this embodiment, the AC dual-control high-voltage matrix frequency conversion electronic control system of the hoist, the high-voltage power supply is connected to the transformer cabinet through the high-voltage vacuum switch cabinet A, and the transformer cabinet is provided with n secondary side coils to output three voltages according to the required voltage requirements. The phase voltage and current are connected to two groups of matrix power units AFR in parallel, and the n matrix power units AFR of each group are respectively connected to their respective control units, and the n matrix power units AFR of each group are connected in series and connected respectively through high-voltage vacuum contact Connectors ZJ1 and ZJ2 are connected to form the row bus output terminals N1 and N2, and then connected to the power control switch HK, and the control unit determines the terminal output U1, V1, W1 of the matrix power u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com