Multipurpose flange structure

A multi-purpose, flange technology, used in flange connections, pipes/pipe joints/fittings, springs/shock absorbers, etc., can solve the difficulty of flange handling, problems in the second operation of equipment, and increase in flange costs. and other problems, to achieve the effect of reducing the transmission of vibration, improving the rigidity of the structure, and improving the shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

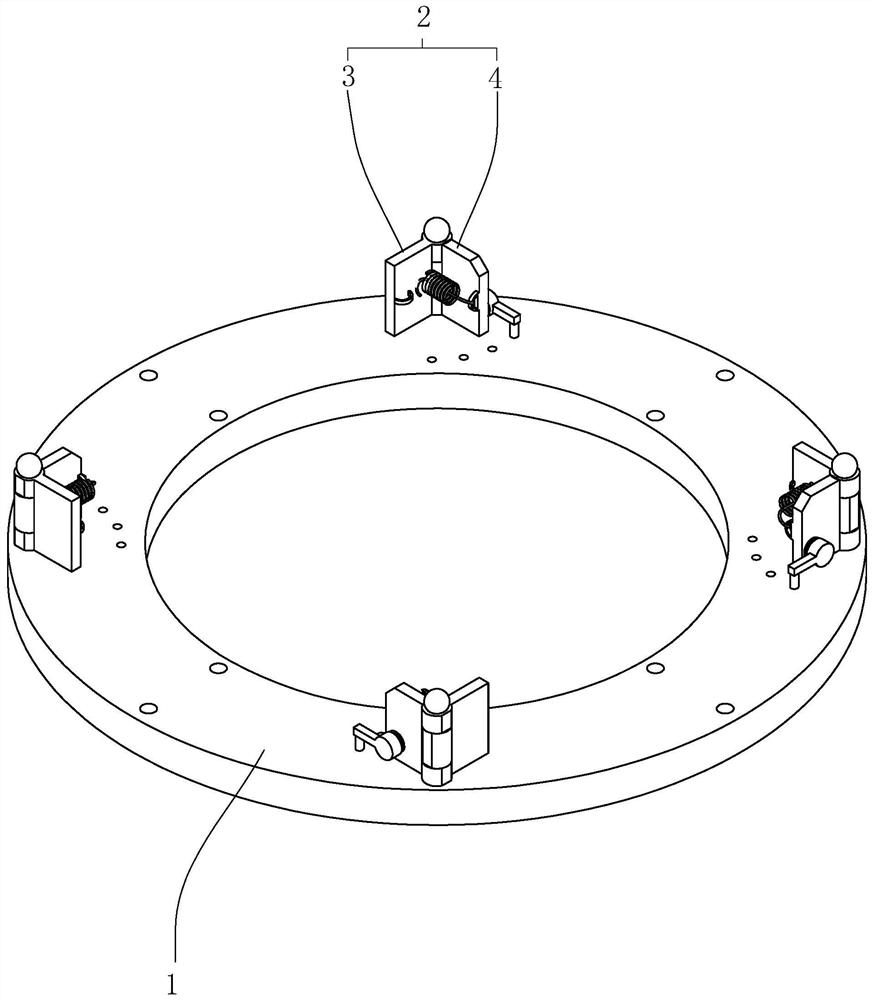

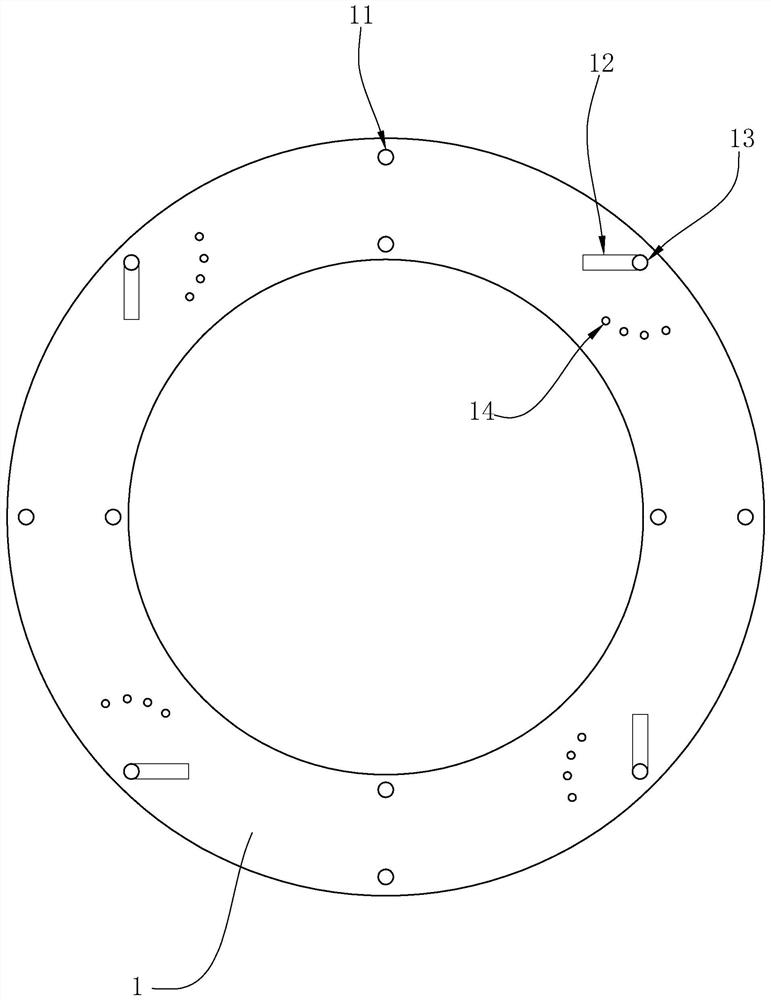

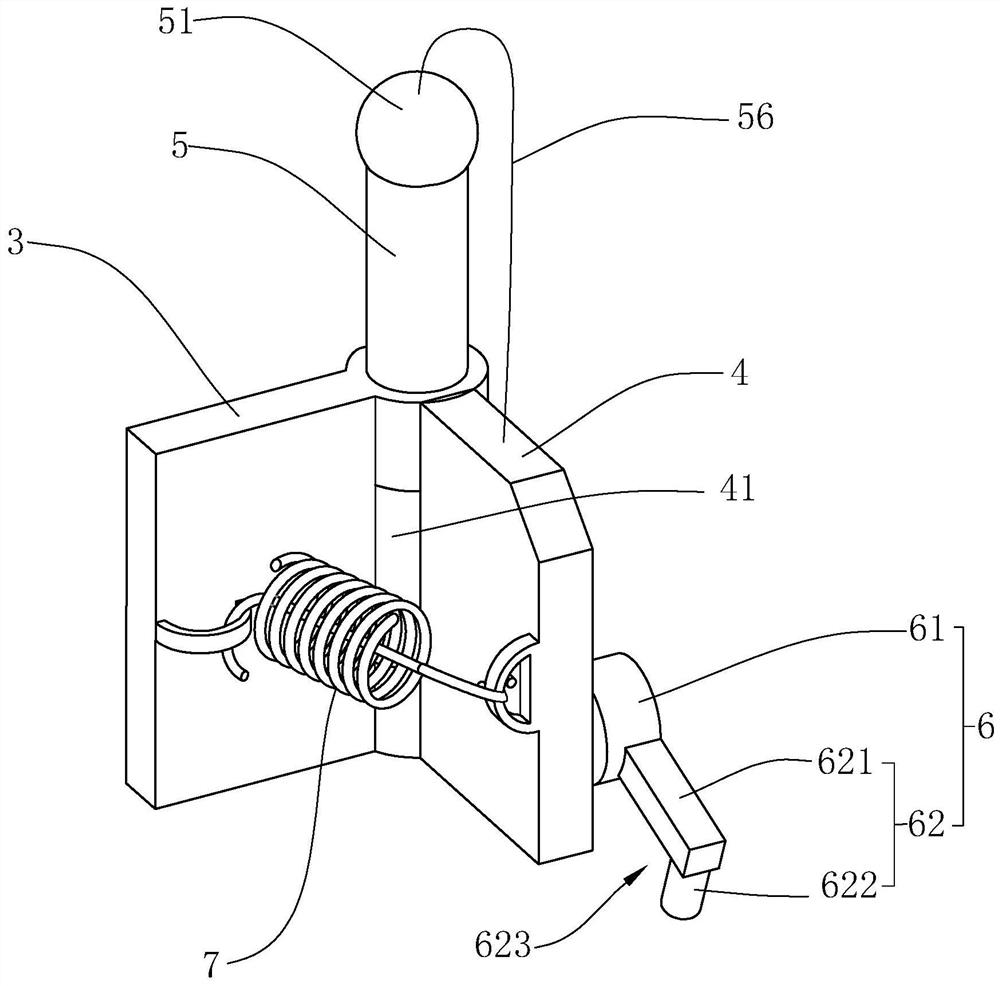

[0031] Such as figure 1 As shown, a multi-purpose flange structure includes a ring body 1, and a plurality of mounting holes 11 are arranged at intervals in the upper direction of the ring body 1, which is convenient for fixing different equipment or devices, and the ring body 1- There are four sets of reinforcement units 2 arranged at intervals in the side circumferential direction. The reinforcement unit 2 includes a fixed piece 3 and a moving piece 4. Both the fixed piece 3 and the moving piece 4 extend along the direction perpendicular to the axis of the ring body 1, and the fixed piece 3 and the moving piece 4 are hingedly arranged, wherein the fixed piece 3 is fixed on the ring body 1, and the moving piece 4 is rotatably adjusted and fixed on the ring body 1 around its hinge axis;

[0032] In order to facilitate the explanation, the axis of the ring bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com