Golf shoe and method for manufacturing same

A golf ball and manufacturing method technology, applied in footwear, shoe soles, clothing and other directions, can solve the problems of incomplete swing action, damaged swing feeling, damage to the best feeling of practice swing, etc., and achieve the effect of improving game ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

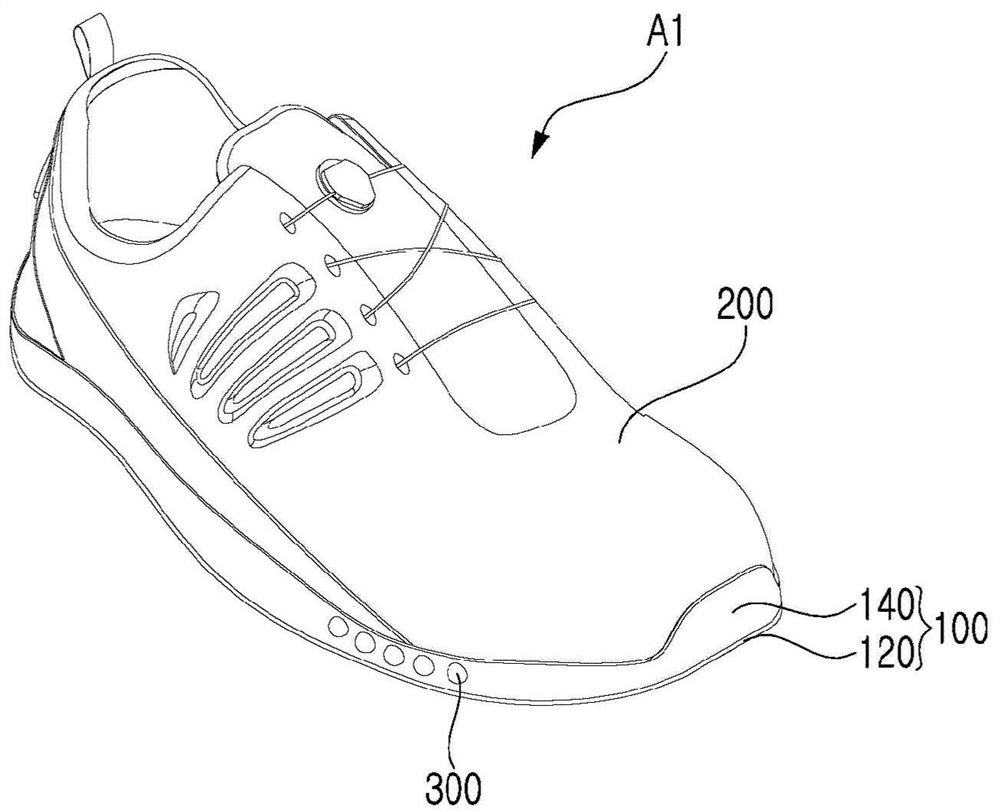

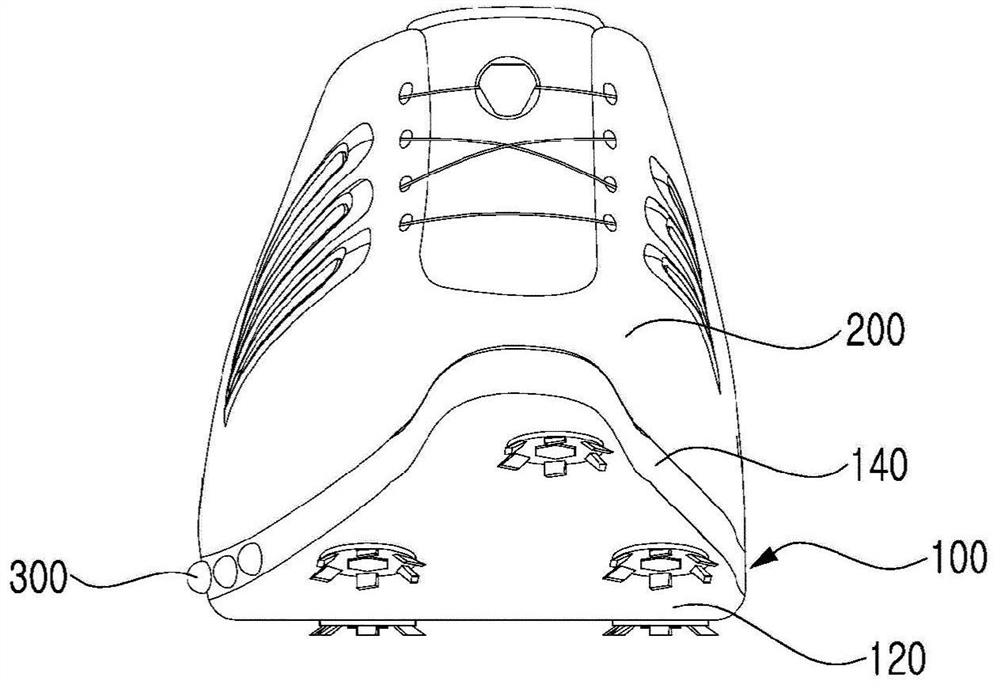

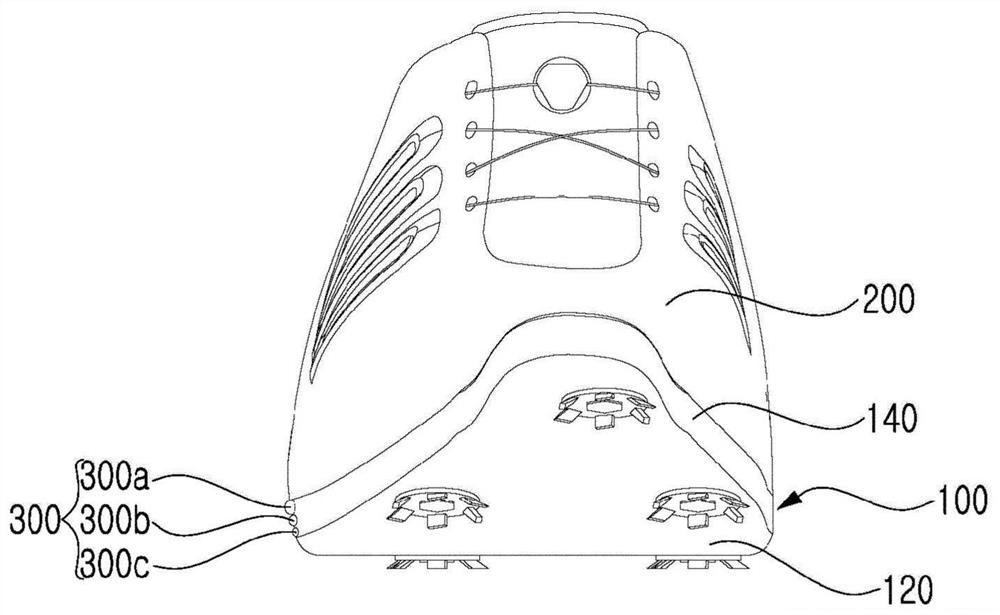

[0035] The golf shoe manufacturing method according to the first embodiment is used to manufacture golf shoes composed of a shoe sole 100 and a shoe upper 200, wherein the shoe sole 100 is made of an outsole 120 and a midsole 140, and the shoe upper 200 is formed on the upper part of the shoe sole 100 , The manufacturing method of the golf shoes includes: the a-th step of injection molding the above-mentioned midsole 140;

[0036] The midsole 140 is molded by injecting raw materials into the mold of the molding device.

[0037] A plurality of grooves are formed in the mold to enable the protrusion 300 to be formed. Therefore, injecting raw materials into the plurality of grooves can form the protrusions 300 on the outer side of the midsole 140 .

[0038] Such as Figure 1 to Figure 6 As shown, the golf shoe A1 according to the first embodiment is constituted to include a sole 100 composed of an outsole 120 and a midsole 140 and an upper 200 formed on the upper portion of the...

no. 2 example

[0061] The golf shoe manufacturing method according to the second embodiment is used to manufacture golf shoes composed of a shoe sole 100 and a shoe upper 200, wherein the shoe sole 100 is made of an outsole 120 and a midsole 140, and the shoe upper 200 is formed on the upper part of the shoe sole 100 , The manufacturing method of the golf shoes includes: the process of injection molding the midsole 140;

[0062] Preferably, protrusions 300 are made of a different material than midsole 140 . For example, the protrusion 300 may be formed of a material having a strength higher than that of the midsole 140 .

[0063] As described above, the plurality of protrusions 300 are formed in one or more rows.

[0064] The above-mentioned plurality of protrusions 300 are formed to have the same or different protrusion heights.

[0065] The golf shoe A2 according to the second embodiment is constituted to include a sole 100 composed of an outsole 120 and a midsole 140, and a shoe upper 2...

no. 3 example

[0080] The manufacturing method of golf shoes according to the third embodiment is used to manufacture golf shoes composed of a shoe sole 100 and a shoe upper 200, wherein the shoe sole 100 is made of an outsole 120 and a midsole 140, and the shoe upper 200 is formed on the upper part of the shoe sole 100 , The manufacturing method of the golf shoes includes: a first step of injection molding the midsole 140; and a second step of planting the brush 500 on the front or rear side of the midsole 140 before the midsole 140 is solidified.

[0081] Such as Figure 7 and Figure 8 As shown, the golf shoe A3 according to the third embodiment is constituted to include a sole 100 composed of an outsole 120 and a midsole 140 and a shoe upper 200 formed on the upper portion of the above-mentioned sole 100,

[0082] A brush 500 is formed on the front side or the rear side of the outer side of the above-mentioned midsole 140 .

[0083] Preferably, the brushes 500 are formed to have differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com