Wooden door

A technology for wooden doors and solid wood, which is applied to door leaves, wooden layered products, chemical instruments and methods, etc., can solve the problems of perishability, cracking and deformation, lack of three-dimensional sense, affecting the beauty of home decoration, etc., and achieves strong surface three-dimensional sense, Improve the fixing firmness, improve the effect of transparency and three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

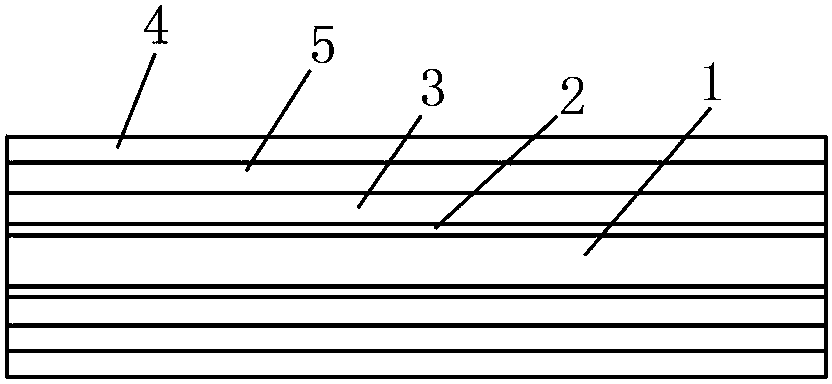

[0024] As shown in the drawings, a wooden door includes a wooden skeleton layer 1, a three-plywood layer 2, a solid wood panel layer 3 and a transparent glass fiber board layer 4 arranged sequentially from inside to outside, and the three-plywood layer 2 is fixed to the wooden skeleton by nails. On layer 1, the plywood layer 2 is glued to the solid wood panel layer 3. The transparent glass fiber board layer 4 is arranged on the inner surface or the outer surface of the solid wood panel layer 3, which can be designed according to actual decoration needs, and can be single-sided or double-sided transparent glass fiber board layer. The transparent glass fiber board layer 4 is glued to the solid wood panel layer 3 .

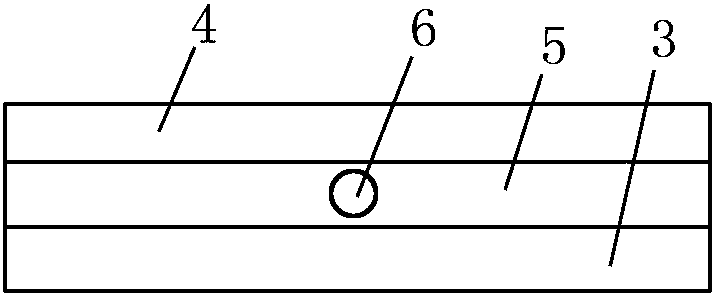

[0025] The transparent glass fiber board layer 4 is connected to the solid wood panel layer 3 through a columnar connecting part, which is a cylindrical metal connector, which can play a role of supporting connection. A cavity 5 is also provided between the transpar...

Embodiment 2

[0027] The difference from the above embodiment is that the transparent glass fiber board layer 4 is closely attached to the solid wood panel layer 3 without a cavity in the middle. The thickness of the door can be reduced. The thickness of the wood skeleton layer 1 is 5 cm, and the thickness of the transparent glass fiber board layer 4 is 1 cm.

[0028] The setting of the three-plywood layer greatly increases the fixed area of the solid wood panel layer, which improves the fixing firmness of the solid wood panel layer. Excessive thermal expansion and contraction, thus prolonging the service life of the door. The wooden door of the present invention has high strength, good weather resistance, long service life, strong three-dimensional effect on the surface, is transparent and beautiful, and plays the role of decorating the wall surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com