Die having cutting edge formed by plurality of blade elements

A technology of knives and components, applied in the field of knives, which can solve the problems of blade instability, arrangement structure and fastening cost, etc., and achieve the effect of simple repair and/or maintenance, short stop time, repair duration or repair duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

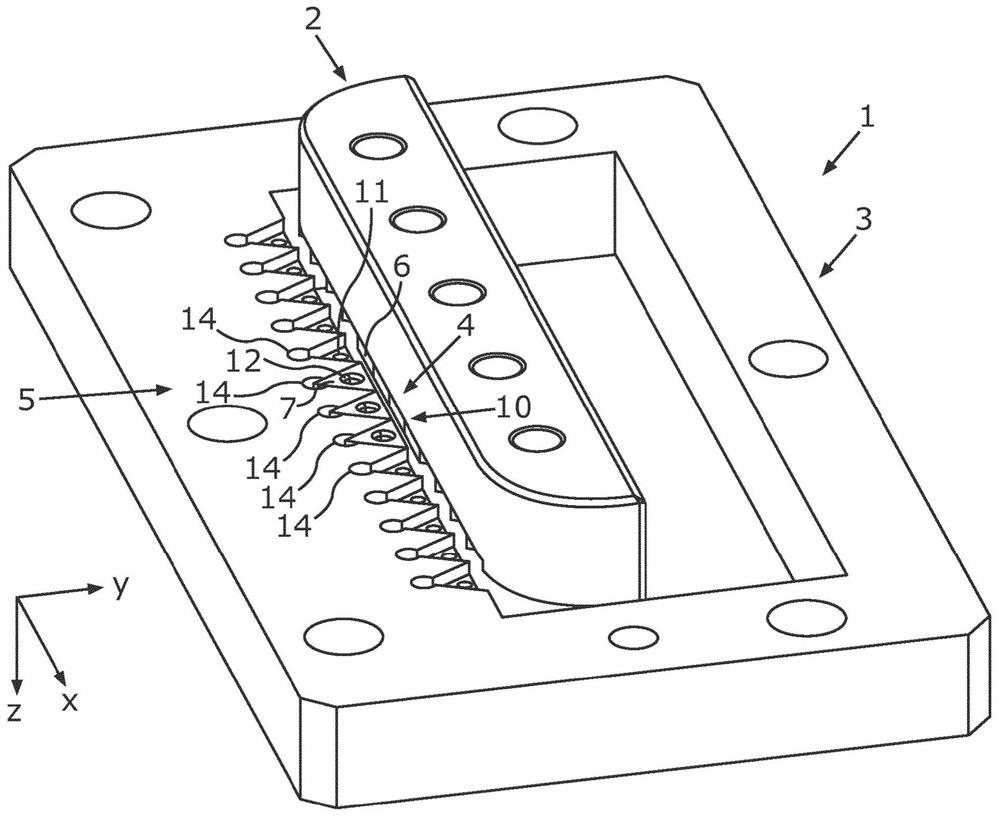

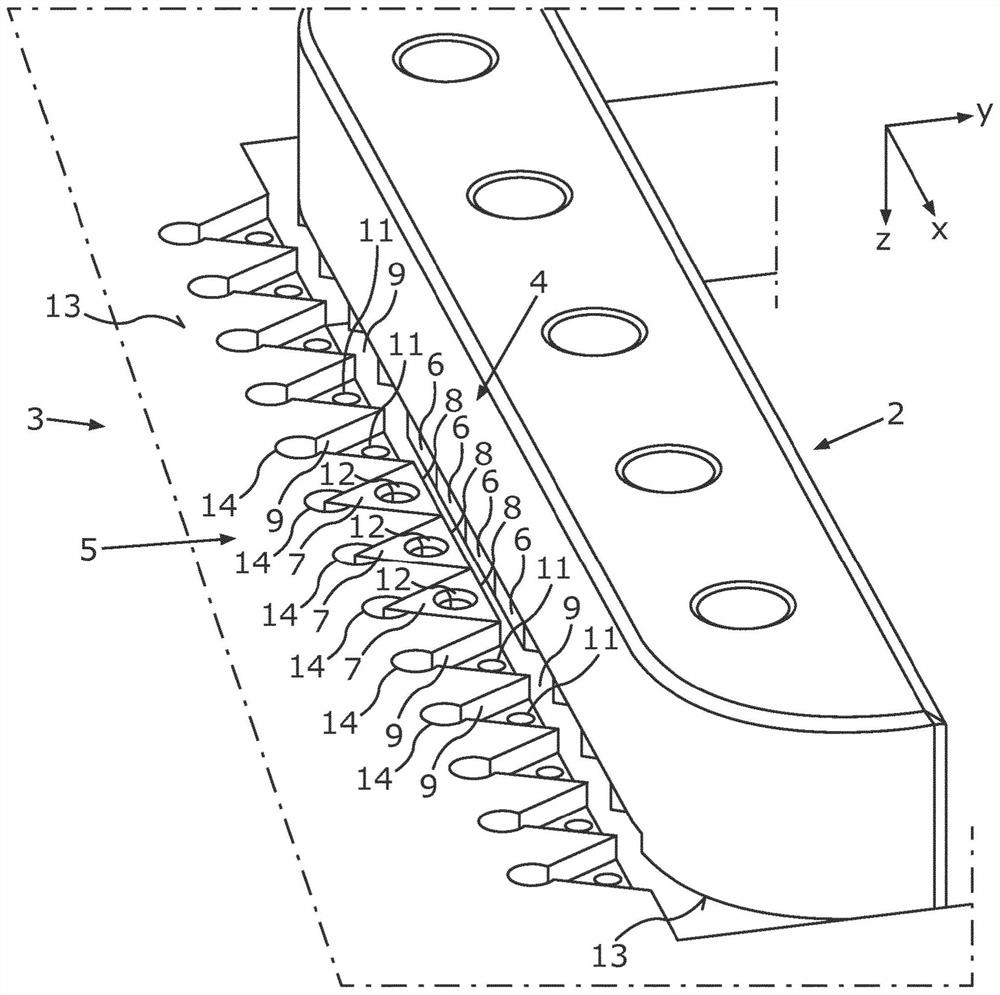

[0034] exist figure 1 schematically and in perspective and in figure 2 The tool 1 shown in more detail in FIG. 1 is provided for cutting workpieces, in particular metal workpieces, and has a first tool part 2 and a second tool part 3 . The first knife part 2 has a first cutting edge 4 and the second knife part 3 has a second cutting edge 5 . For cutting, for example cutting and / or breaking off a workpiece, the tool 1 or the tool parts 2, 3 can be adjusted into an open position in which it is possible to arrange, for example, between the two tool parts 2, 3 Put in the workpiece. For example, the workpiece to be cut can be a sheet-shaped shaped metal body, for example a metal sheet, a coil or the like. If the workpiece is arranged between the tool parts 3, 4 or between the cutting edges 4, 5, the tool parts 2, 3 can be moved towards each other from the open position into the breaking position, whereby the cutting edges 4, 5 first plastically deform the workpiece and Finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com