Conveying detection mechanism and working method

A detection mechanism and camera technology, applied in conveyors, labeling machines, transportation and packaging, etc., can solve the problems of time-consuming and laborious, and achieve the effect of wide adaptability, stable operation and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

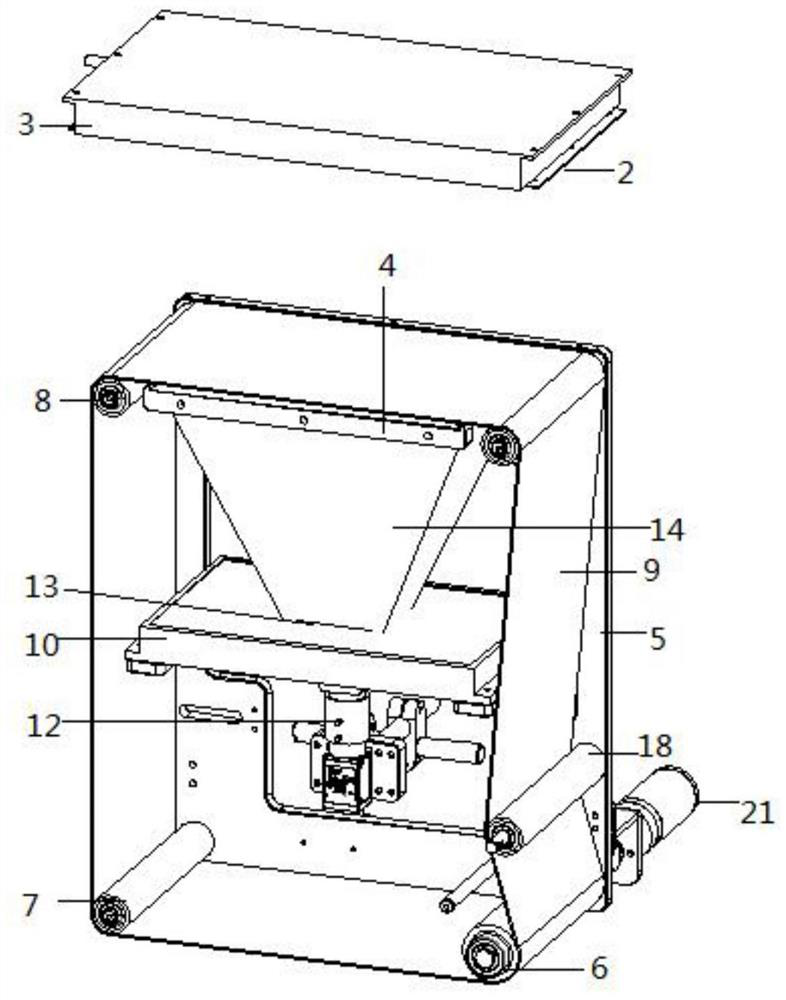

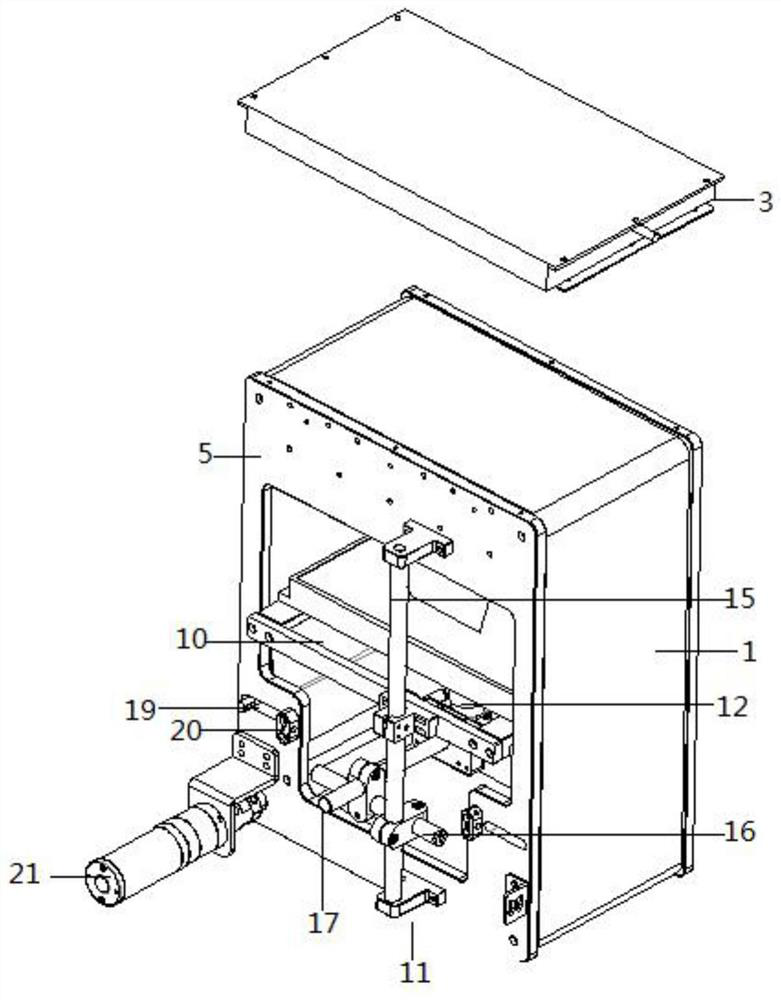

[0026] according to figure 1 and figure 2 The conveying detection mechanism shown includes a frame 1, an upper light source 3 is installed on the top of the frame 1 through an upper fixing bracket 2, a lower visual glass 4 is fixed on the upper inner side of the frame 1, and the front and rear sides of the frame 1 are installed There is a fixed plate 5, the lower visual glass 4 is located below the upper light source 3, the inner bottom side of the frame 1 is provided with a rubber-coated driving roller 6, and the other side of the inner bottom of the frame 1 is provided with a rubber-coated driven roller 7. There are rubber-coated driven rollers I8 on both sides of the inner upper part. The rubber-coated driving roller 6 is connected to the rubber-coated driven roller 7 and the rubber-coated driven roller I8 through a transparent belt 9. The transparent belt 9 passes through the lower visual glass. Above 4, the ends of the rubber-coated driving roller 6, the rubber-coated d...

Embodiment 2

[0028] according to figure 1 and figure 2 The conveying detection mechanism shown includes a frame 1, an upper light source 3 is installed on the top of the frame 1 through an upper fixing bracket 2, a lower visual glass 4 is fixed on the upper inner side of the frame 1, and the front and rear sides of the frame 1 are installed There is a fixed plate 5, the lower visual glass 4 is located below the upper light source 3, the inner bottom side of the frame 1 is provided with a rubber-coated driving roller 6, and the other side of the inner bottom of the frame 1 is provided with a rubber-coated driven roller 7. There are rubber-coated driven rollers I8 on both sides of the inner upper part. The rubber-coated driving roller 6 is connected to the rubber-coated driven roller 7 and the rubber-coated driven roller I8 through a transparent belt 9. The transparent belt 9 passes through the lower visual glass. Above 4, the ends of the rubber-coated driving roller 6, the rubber-coated d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com