Automatic sponge feeding device

An automatic feeding and sponge technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of randomness, high labor intensity of manual handling of sponge blocks, and handling of wrong products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

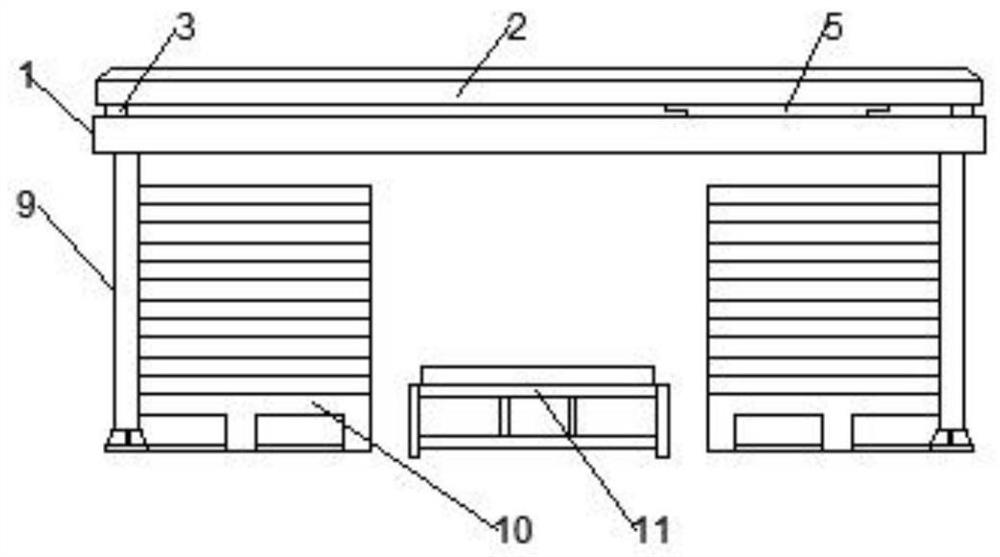

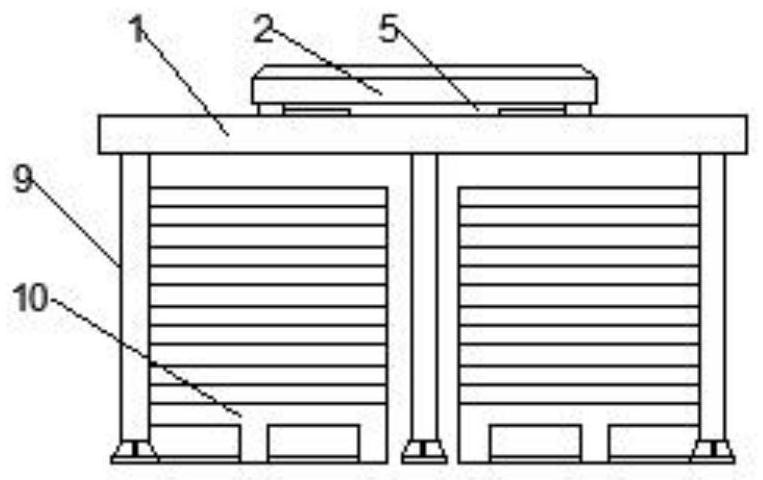

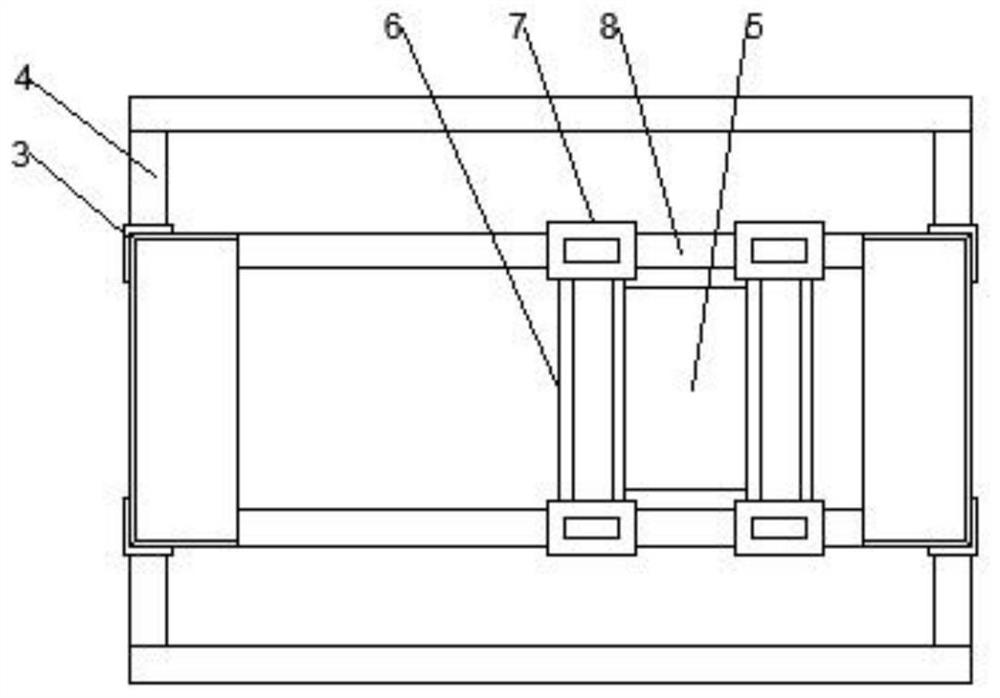

[0027] see Figure 1-7 , the present invention provides a technical solution: an automatic sponge feeding device, including a first support 1, the first support 1 is square and hollow, and the top surfaces of both sides of the first support 1 are symmetrically provided with a second A guide rail 4, specifically, the first guide rail 4 is fixedly connected to the first support 1, the second support 2 is provided above the first support 1, and the first sliding assembly is provided on both sides of the bottom surface of the second support 2 3. Specifically, the first sliding assembly 3 is fixedly connected to the second support 2, and the first sliding assembly 3 is mated and connected to the first guide rail 4. Specifically, the first sliding assembly 3 is slidingly connected to the first guide rail 4. The first The sliding assembly 3 is connected with a servo motor, and second guide rails 8 are provided on both sides of the bottom surface of the second support 2, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com