Anti-falling lifeline under complex environmental conditions

A complex environment, anti-fall technology, applied in the field of lifeline, can solve problems such as limited interference installation positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described below with reference to the accompanying drawings and specific embodiments.

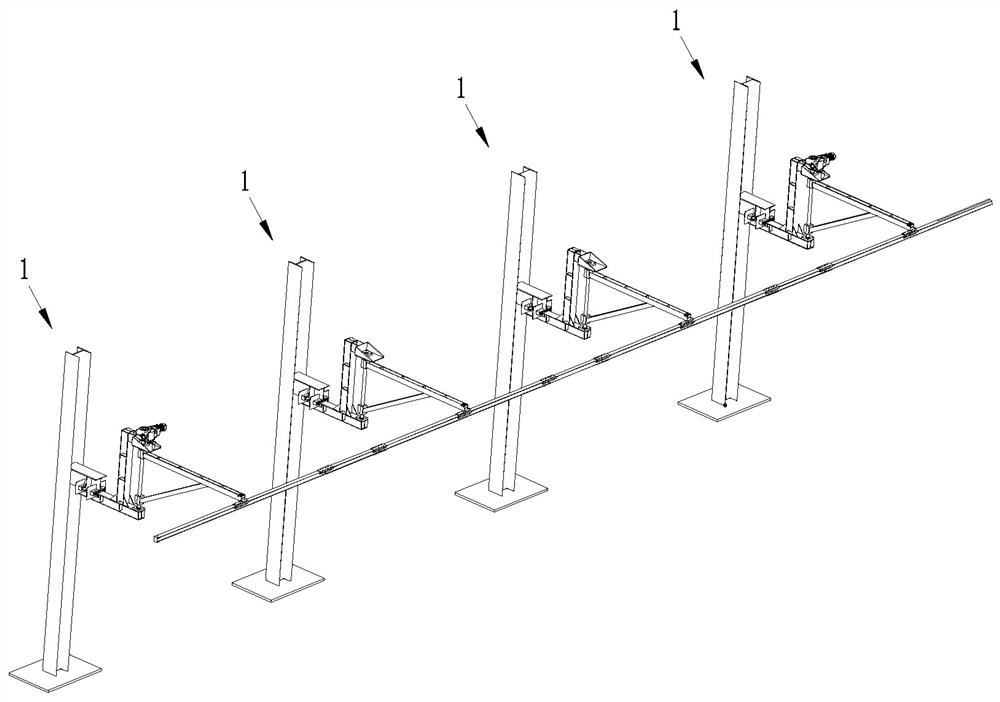

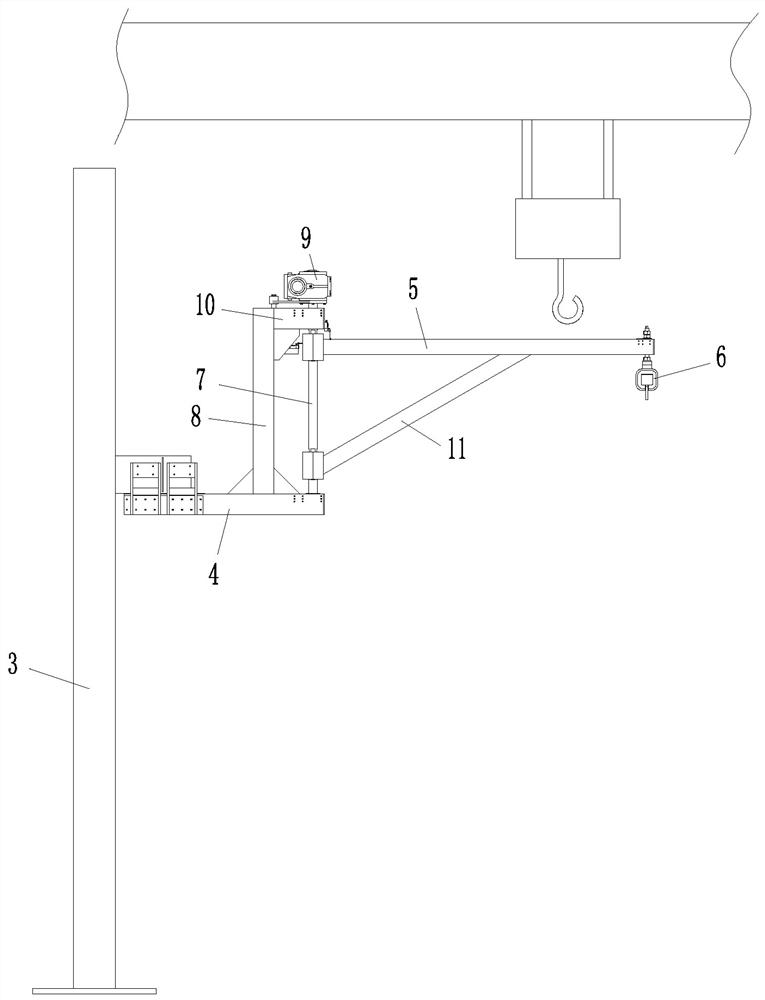

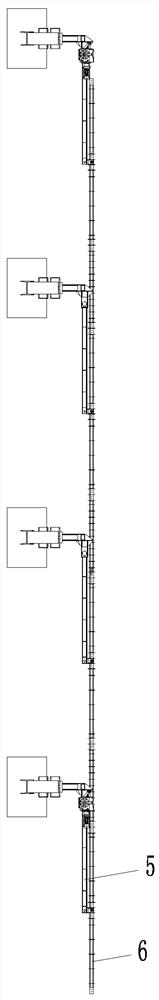

[0024] Such as Figure 1-5 As shown, a complex environmental condition defensive lifetime, including several intervals set of anti-fall lifeline unit 1, and a bridge jack 2 is provided above the falling life line.

[0025] The anti-fall life line unit 1 includes a column 3, a projecting arm 4, a mount, a movable arm 5, and a tail, and the column 3 is vertically disposed on the ground, and the extension arm 4 includes a fixed end and an extension, extending the arm 4. The fixed end is fixed to the column 3, and the mounting holder is fixed to the extended out of the projectile arm 4, and one end of the movable arm 5 is rotated on the mounting seat, and the tail 6 is mounted on the extension of the active arm 5, the tail 6 and Active arm 5 rotates.

[0026] The mount includes a rotation shaft 7 that is rotatably mounted on the top of the extended arm 4, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com