Powder coal pressure transmission system and method of fuel coal gasification entrained-flow bed

A transportation system and coal gas-fired technology, which is applied in the direction of granular/powdered fuel gasification, gasification process, and production of combustible gas, etc., can solve the problems of low gas compression efficiency, polluting energy, high energy consumption, etc., and extend the service life , reduce investment, improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

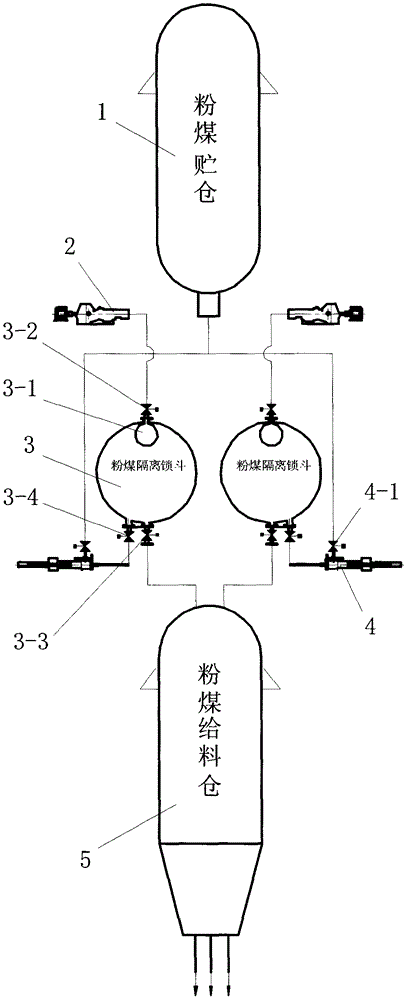

[0058] Example 1: figure 1 middle,

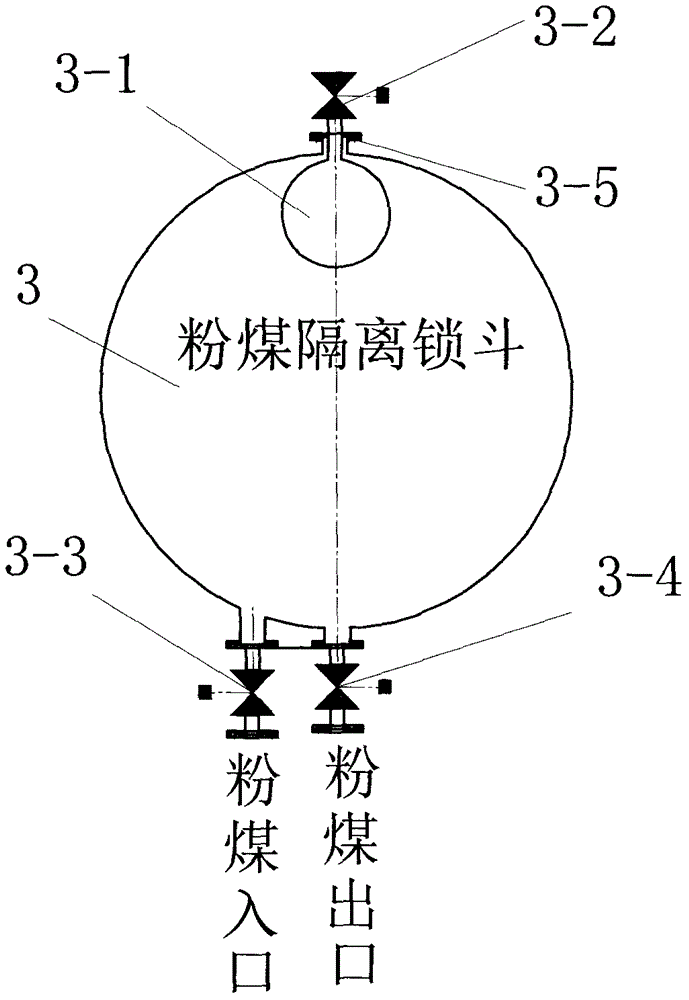

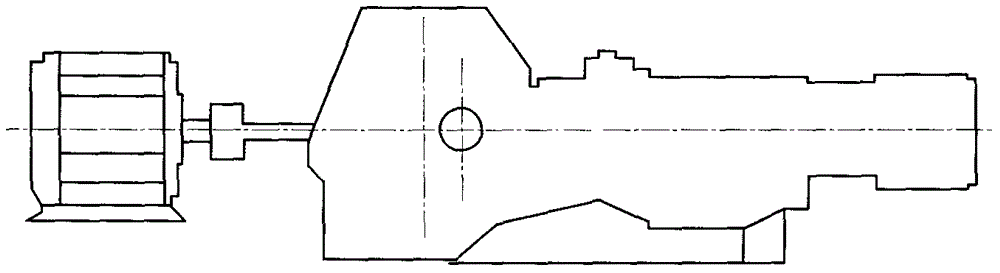

[0059] The pressurized conveying system includes: pulverized coal storage bin 1; high-pressure plunger pump 2; pulverized coal isolation lock hopper 3; hydraulic double plunger dry powder pump 4; pulverized coal feeding bin 5; Double plunger dry powder pump 4, pulverized coal isolation lock hopper 3, and pulverized coal feed bin 5 are sequentially connected; the outlet of hydraulic double plunger dry powder pump 4 and the inlet of pulverized coal isolation lock hopper are connected by pipelines, and hydraulic double plunger dry powder pump 4 A lock hopper valve is set at the entrance; a lock hopper valve is set between the pulverized coal isolation lock hopper and the pulverized coal feeding bin 5 . The outlet of the high-pressure plunger pump 2 is connected to the inlet of the pulverized coal isolation lock bucket isolation device by a pipeline.

[0060] The pulverized coal isolation lock bucket is equipped with an isolation device insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com