Developing roller

A developing roller and surface layer technology, applied in the field of developing rollers, can solve the problems of damaged film formation and toner blocks, image formation and printing quality degradation, excessive increase, etc., to achieve the goal of suppressing excessive increase and reducing toner damage Effect

Pending Publication Date: 2021-03-23

株式会社アーケム

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to poor charging of toner, poor adhesion of toner, and melting and sticking of toner, toner damage leads to filming and toner clumping, etc., all of which lead to a decrease in the amount of toner conveyed by the developing roller. Excessive increase, causing problems in image formation and print quality deterioration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0130] The present disclosure is described in more detail below with reference to Examples, which should not be construed as limiting the scope of the present disclosure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

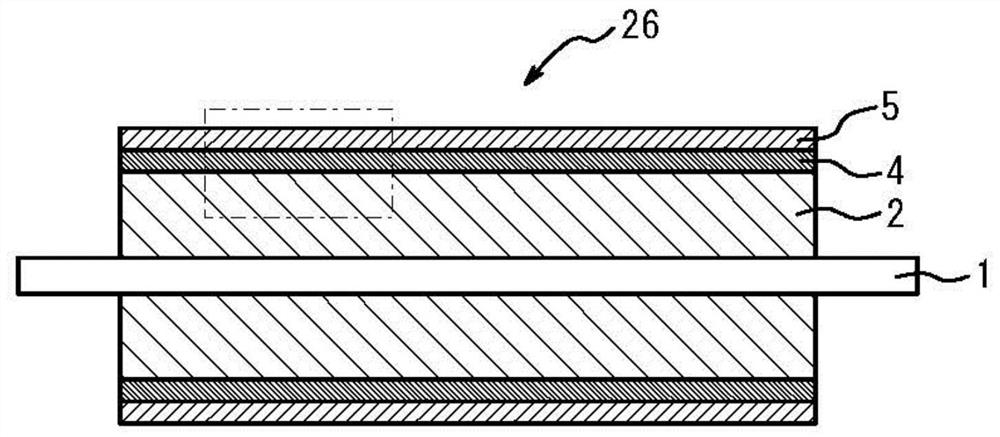

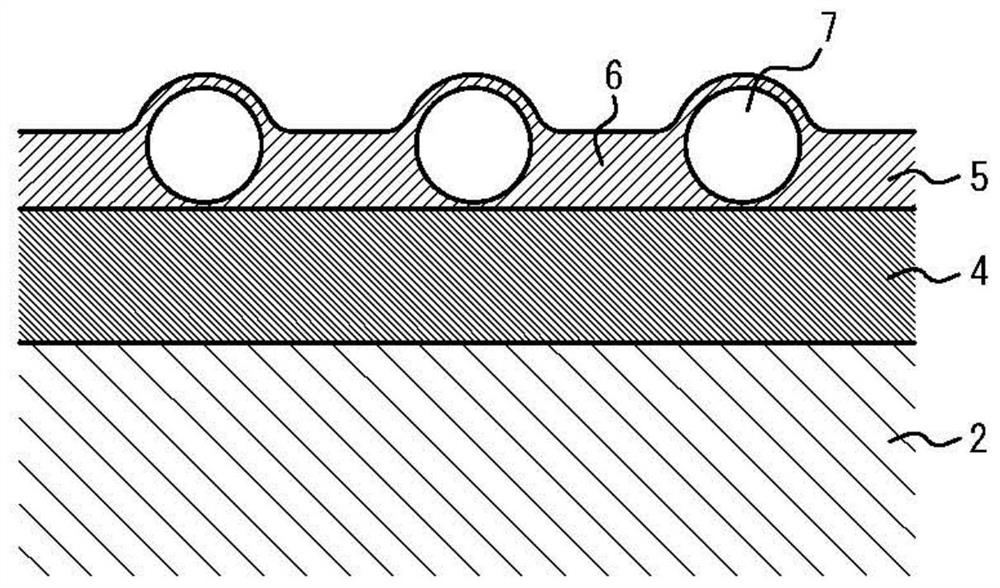

The invention relates to a developing roller. Provided is a developing roller including a shaft, and a base layer and a surface layer sequentially formed in a radial direction on an outer peripheral portion of the shaft, in which 1) a low-resilience layer is provided between the base layer and the surface layer, 2) when measured under conditions of a temperature of 23 DEG C, an amplitude of + / -20[mu] m, and a frequency of 6 Hz, the low-resilience layer is provided between the base layer and the surface layey, wherein the loss tangent tan [delta] value of the low-resilience layer is greater than any one of the loss tangent tan [delta] values of the base layer and the surface layer, and 3) the Asker C hardness / thickness value of the developing roller as defined by the following formula (1)is 500 or less: Asker C hardness / thickness value of the developing roller = Asker C hardness of the developing roller * (thickness of the developing roller + 6) (1).

Description

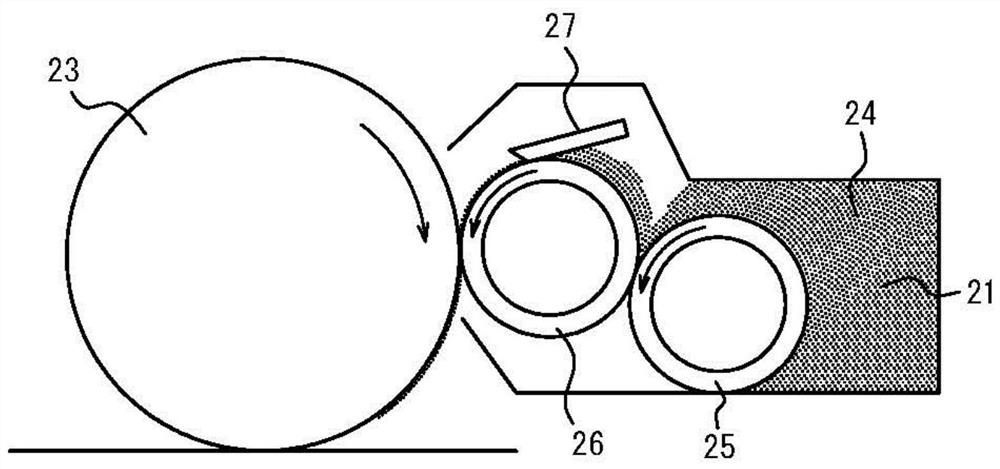

technical field [0001] The present disclosure relates to a developer roller. Background technique [0002] In an image forming apparatus typified by a copier, or a laser beam printer, etc., image formation and printing are performed through the following series of processes, and the series of processes are repeated periodically: [0003] 1) Evenly charge (charge) the surface of the photoreceptor; [0004] 2) The image of the target is read by the optical system, the image information is projected on the photoreceptor as light (exposure), and a latent image is formed by eliminating the charge of the exposed part of the photoreceptor (formation of electrostatic latent image); [0005] 3) Adhering toner to a photoreceptor on which an electrostatic latent image has been formed, and forming a toner image from the electrostatic latent image (development); [0006] 4) Overlaying the toner image on a recording medium such as paper and fixing (transferring and fixing); [0007] 5)...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03G15/08

CPCG03G15/0818G03G15/0808

Inventor 藤泽祐辅山下聪太郎

Owner 株式会社アーケム

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com