Material distribution mode optimization system

A material and subsystem technology, applied in the field of material distribution mode optimization system, can solve problems such as low material distribution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

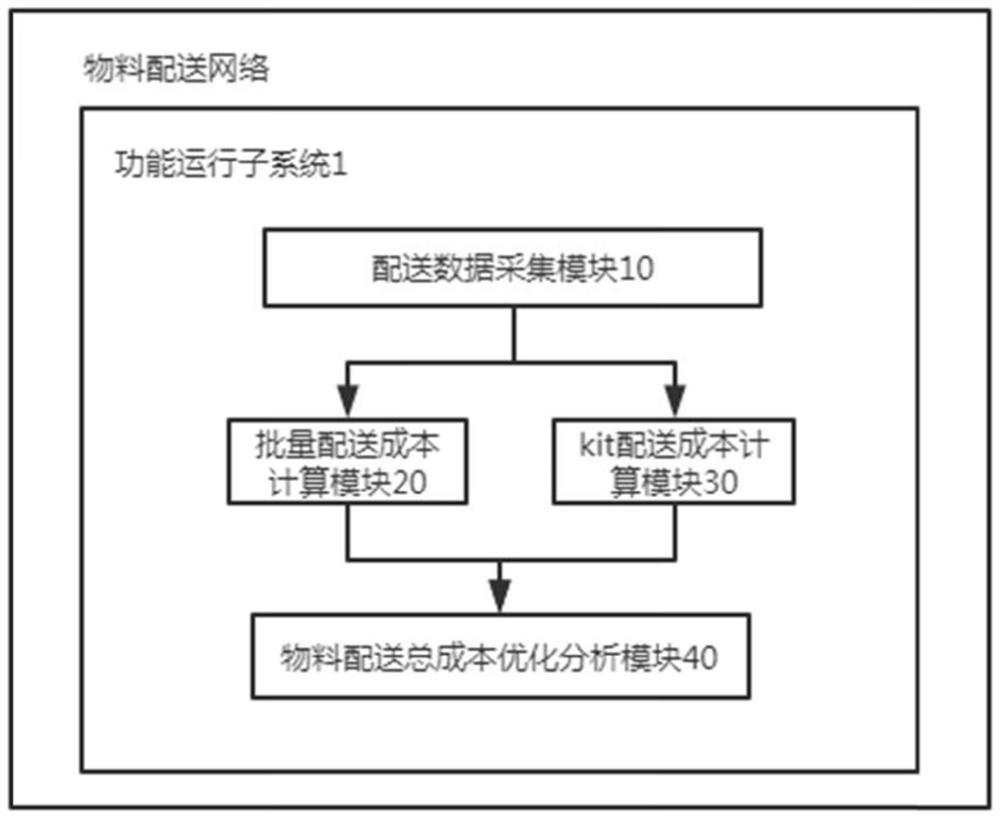

[0057] DETAILED DESCRIPTION One: Refer to figure 1 Specifically, the present embodiment will be described in the present embodiment, including: a material distribution network composed of a function operating subsystem 1, the functional operation subsystem 1 includes: a distribution data acquisition module 10. Batch distribution cost calculation module 20, Kit Distribution Cost Calculation Module 30 and Material Distribution Total Cost Optimization Analysis Module 40;

[0058] The distribution data acquisition module 10 is used to obtain the distance between the various regions of the production workshop, the shortage of different types of materials, and paying wages of different functional staff;

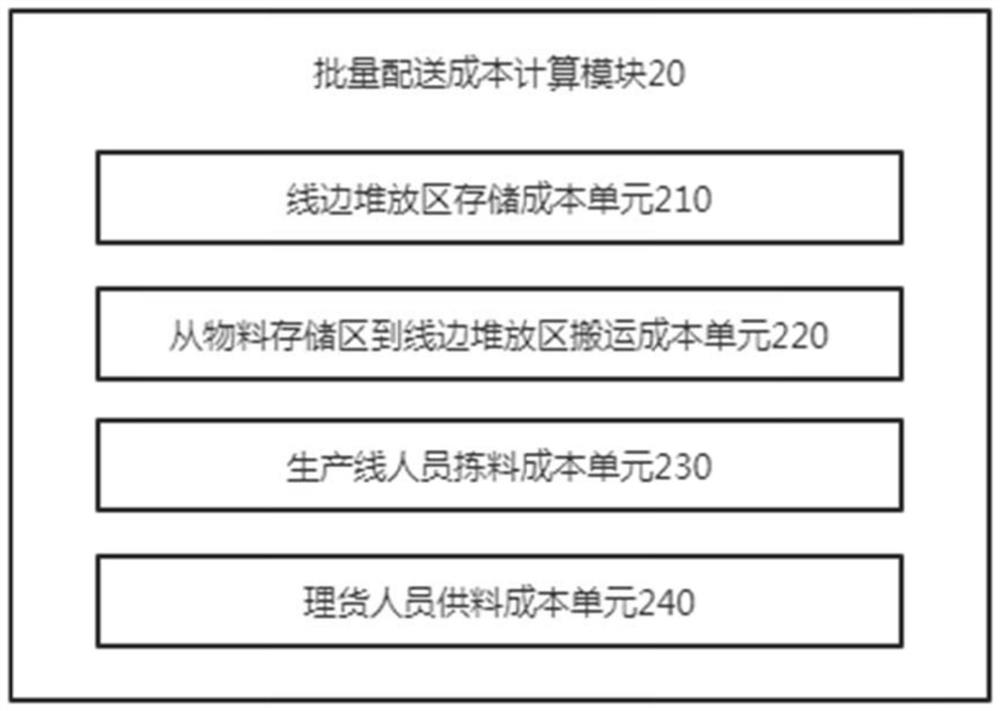

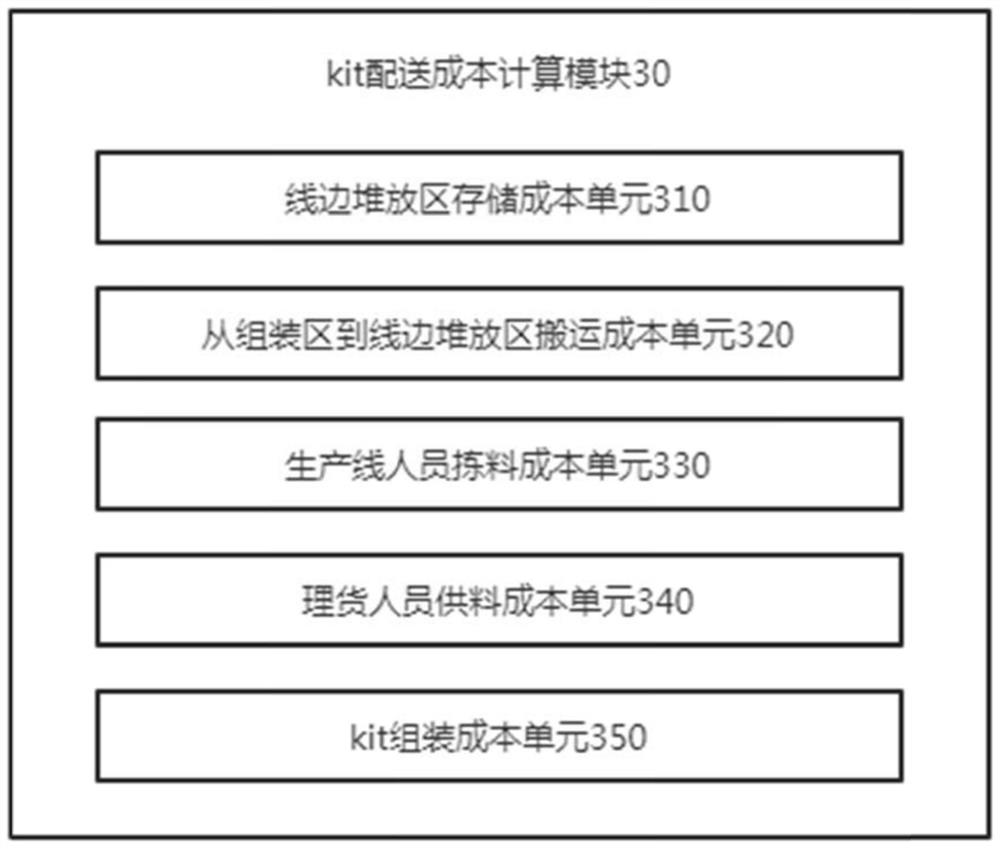

[0059] The batch distribution cost calculation module 20 is configured to calculate the storage cost of the linear stack of lines under mass delivery according to the data acquired by the distribution data acquisition module, from the transportation cost of the material storage area t...

Embodiment

[0119] By mass distribution and KIT delivery, the relevant data acquisition module 10 is in terms of production companies, understand the specific processes of material distribution under mass delivery and Kit delivery. Communicate communicate with staff and combine the existing data and experience on the network, master the distance between the districts between the production workshop, the first-hand information of the payment of different types of materials, the payroll of different function staff. In this embodiment, a model of a model is a research object, and the number of items involved is 451, and the production line is "U" type, involving 27 stations. Only the values of the fixed parameters are listed here, as shown in the following table.

[0120]

[0121] The cost of distribution cost calculation module 20 under volume delivery has four costs: the storage cost of the line-edge stacking area, from the transportation cost of the material storage area to the line, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com