Preparation method of hot compress plaster

A technology of hot compress and heating body, which is applied in the direction of heating equipment for treatment, cooling equipment for treatment, external support, etc., which can solve the problem of low sealing efficiency of film bags, occupying the usable area of the site, and not being able to use multiple film bags Heat-press sealing and other problems, to achieve the effect of high sealing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of hot compress, comprising the following steps:

[0038] Step 1: In parts by weight, weigh 40 parts of iron powder, 10 parts of activated carbon, 1 part of sodium chloride, and 5 parts of water, add iron powder, activated carbon, sodium chloride, and water into the mixer, mix evenly, and obtain heat generation body;

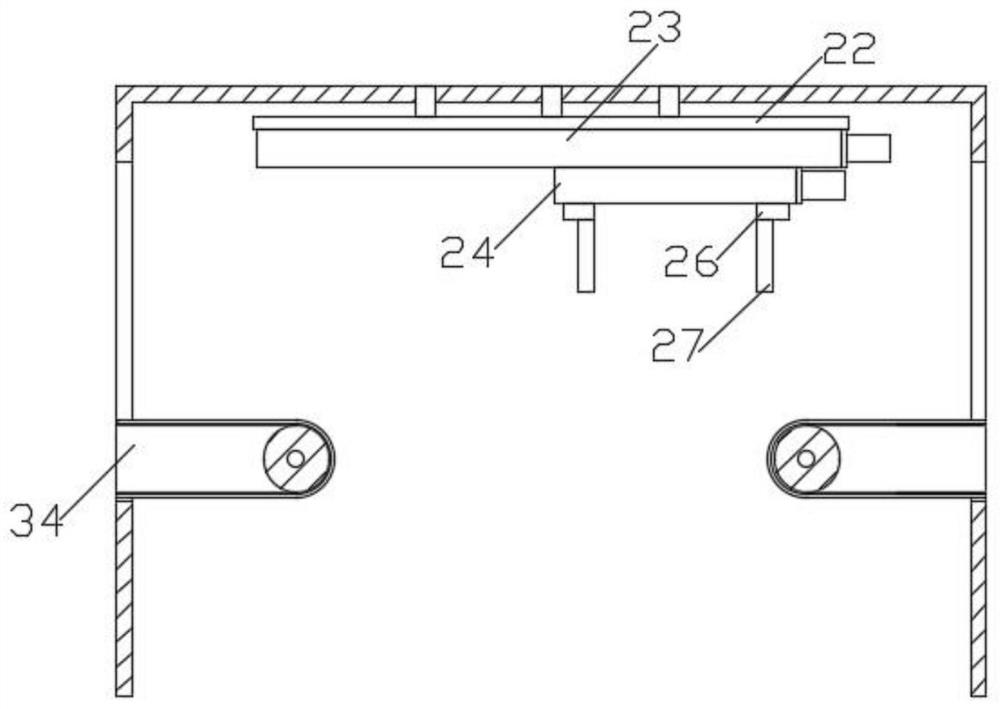

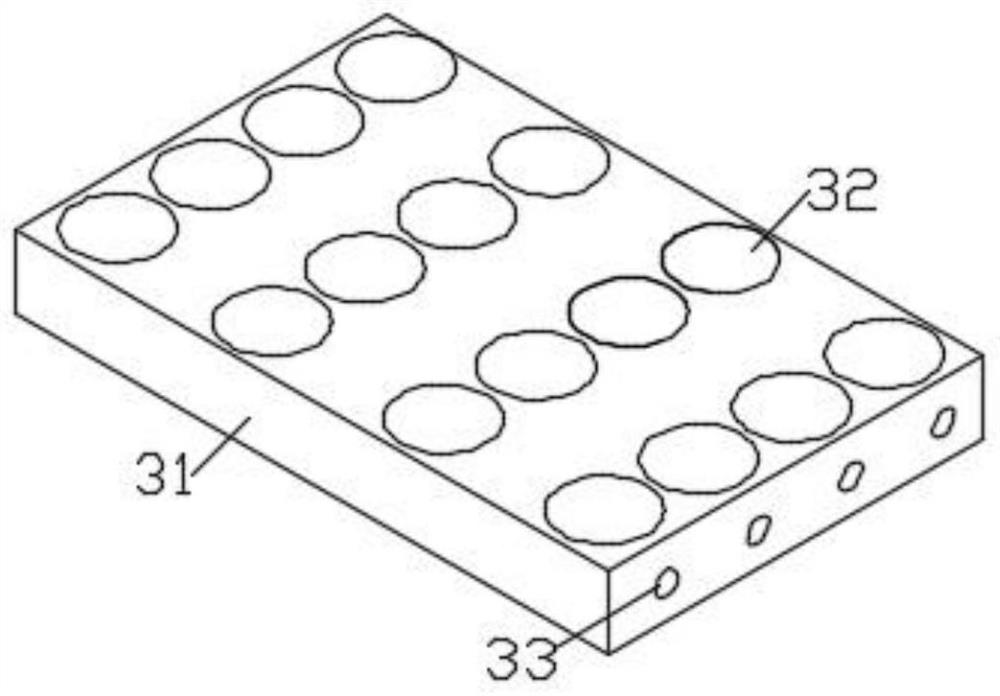

[0039] Step 2: Add isobutylene-maleic anhydride copolymer solution into the dipping tank 21 of the heat-sealing dipping equipment, then add aluminum sulfate octadecahydrate into the dipping tank 21, put the heating element into a perforated film bag, and put the The perforated film bag with heating element is put into the columnar groove 32 on the impregnation plate 31, and the impregnation plate 31 is placed on the belt conveyor 34 on the feeding chamber 1, and the belt conveyor 34 transports the impregnation plate 31 to the supporting frame 4 On the tray 10 at the top, the micro-movement cylinder 205 piston rod pushes the guide blo...

Embodiment 2

[0042] A preparation method of hot compress, comprising the following steps:

[0043] Step 1: In parts by weight, weigh 90 parts of iron powder, 30 parts of activated carbon, 12 parts of sodium chloride, and 25 parts of water, add iron powder, activated carbon, sodium chloride, and water into the mixer, mix evenly, and obtain heat generation body;

[0044] Step 2 is the same as in Example 1.

[0045] Concrete, the quality of the isobutylene-maleic anhydride copolymer in the isobutylene-maleic anhydride copolymer solution in step 2 is 4% of the quality of water, and the quality of aluminum sulfate octadecahydrate is the water in the isobutylene-maleic anhydride copolymer solution 6% of the mass.

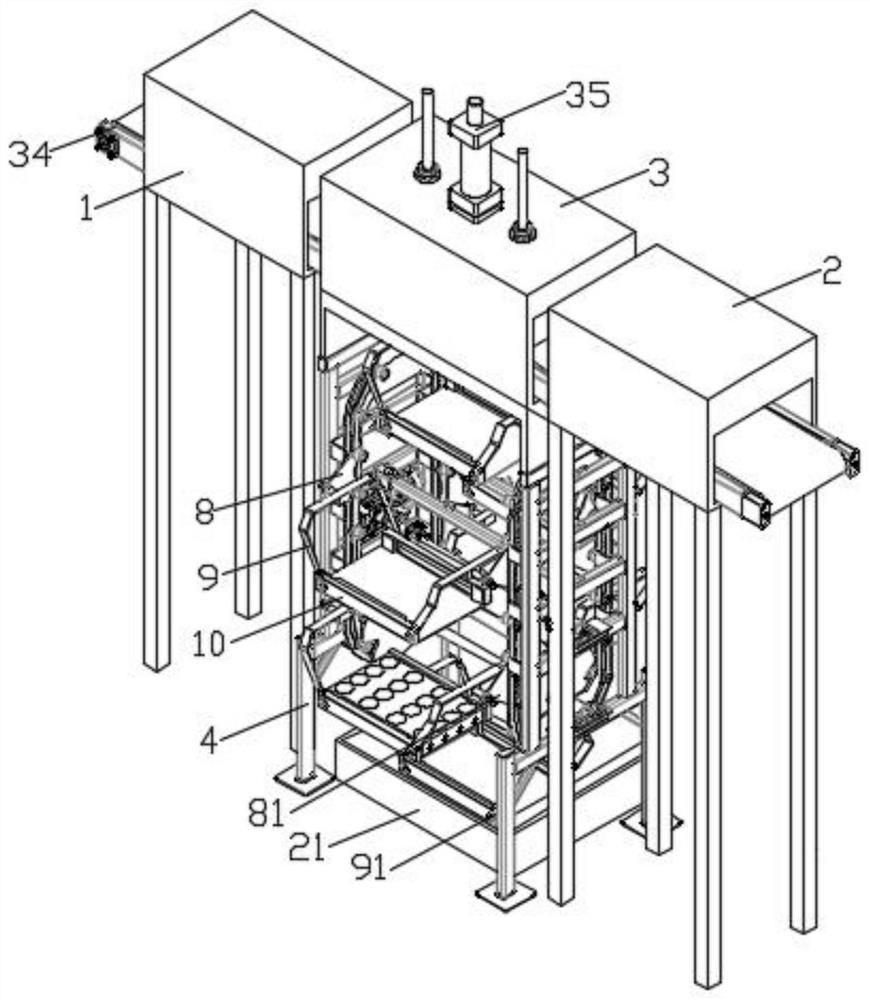

[0046] The heat sealing and impregnating equipment includes a heat sealing chamber 3, which is installed on a support frame 4, and the two sides of the heat sealing chamber 3 are respectively provided with a feed chamber 1 and a discharge chamber 2, and the support frame 4 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap