Self-tapping and self-locking bolt

A bolt and self-locking technology, which is applied to workshop equipment, hand-held tools, workpiece clamping devices, etc., can solve the problems of self-tapping screw drilling direction deviation, affecting work efficiency, etc., and achieve the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

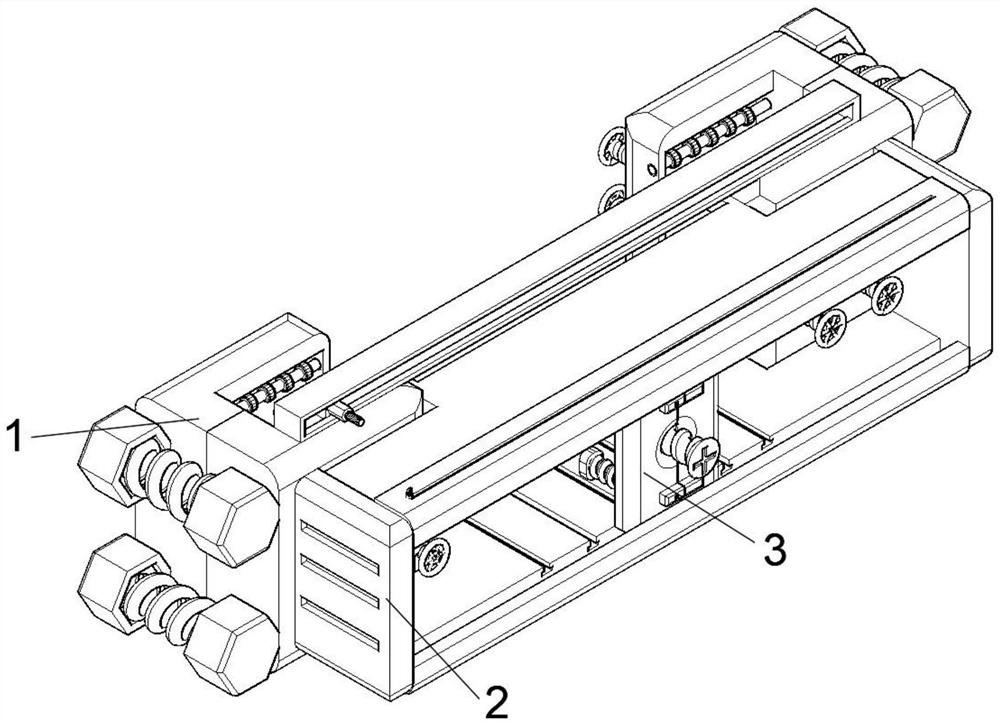

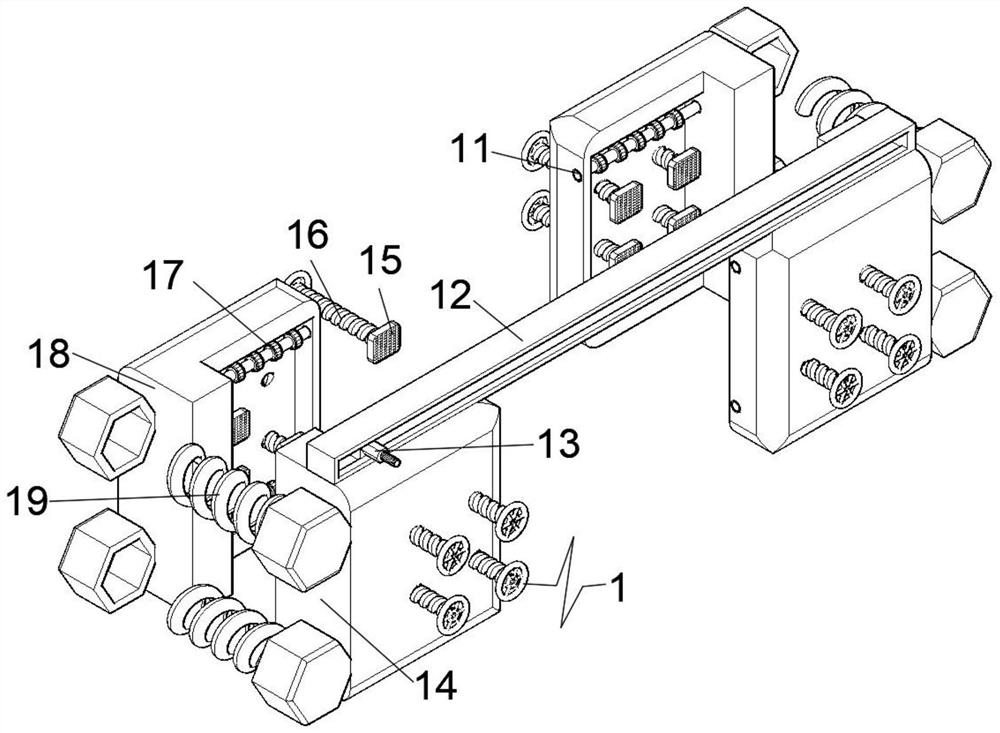

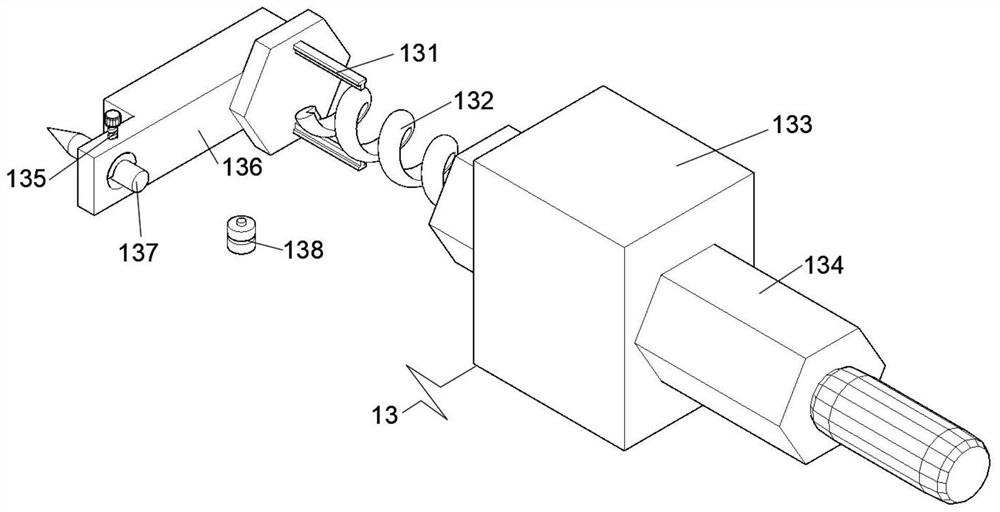

[0026] Such as Figure 1-Figure 6As shown, a self-tapping and self-locking bolt according to the present invention includes a load-bearing chute frame 2, and an auxiliary tapping plate 3 is slidingly clamped inside the load-bearing chute frame 2, and one side of the load-bearing chute frame 2 is symmetrically fixed Welded with a fixed scriber 1, the bearing chute frame 2 includes an open slot 21, a paddle 22, a chute plate 23, a first chute 24, a second chute 25 and a third chute 26, the second chute 25 is symmetrically provided at the inner top and bottom of the chute plate 23, and the third chute 26 is symmetrically and equally spaced at the inner top and bottom of the chute plate 23, and the third chute 26 is located behind the second chute 25....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com