High-stability multi-layer loading equipment for novel ceramic part

A loading equipment and high stability technology, which is applied in the direction of lighting and heating equipment, lighting device parts, lighting devices, etc., can solve the problems of fragile ceramic parts, small loading capacity, bumpy transportation, etc., to reduce dust erosion, Achieve the effect of blocking dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

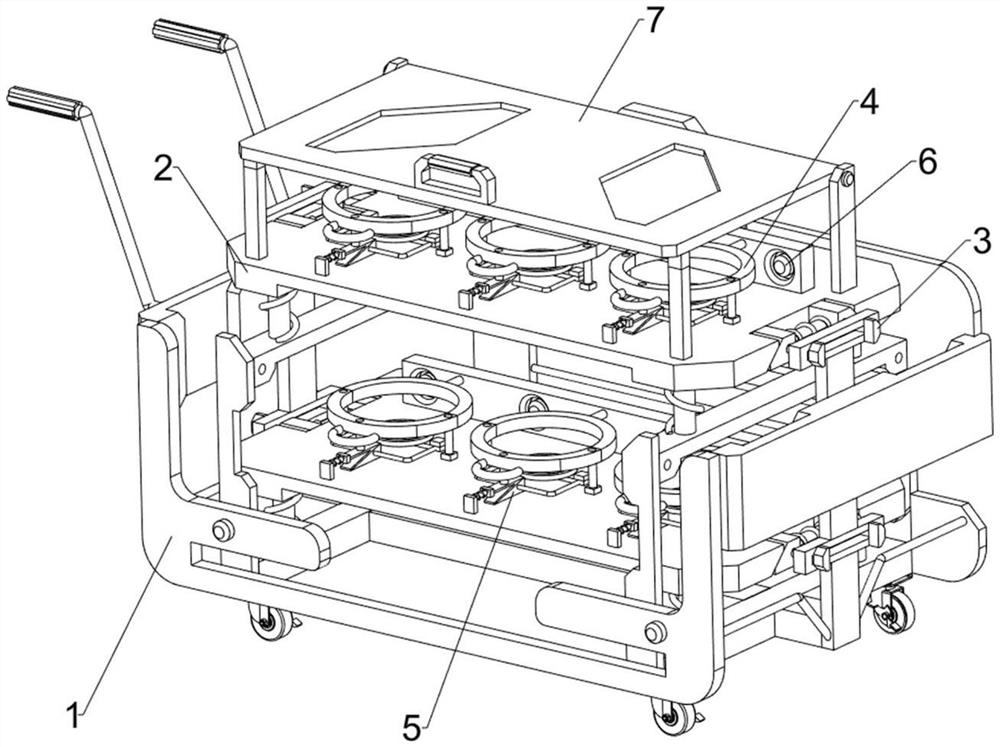

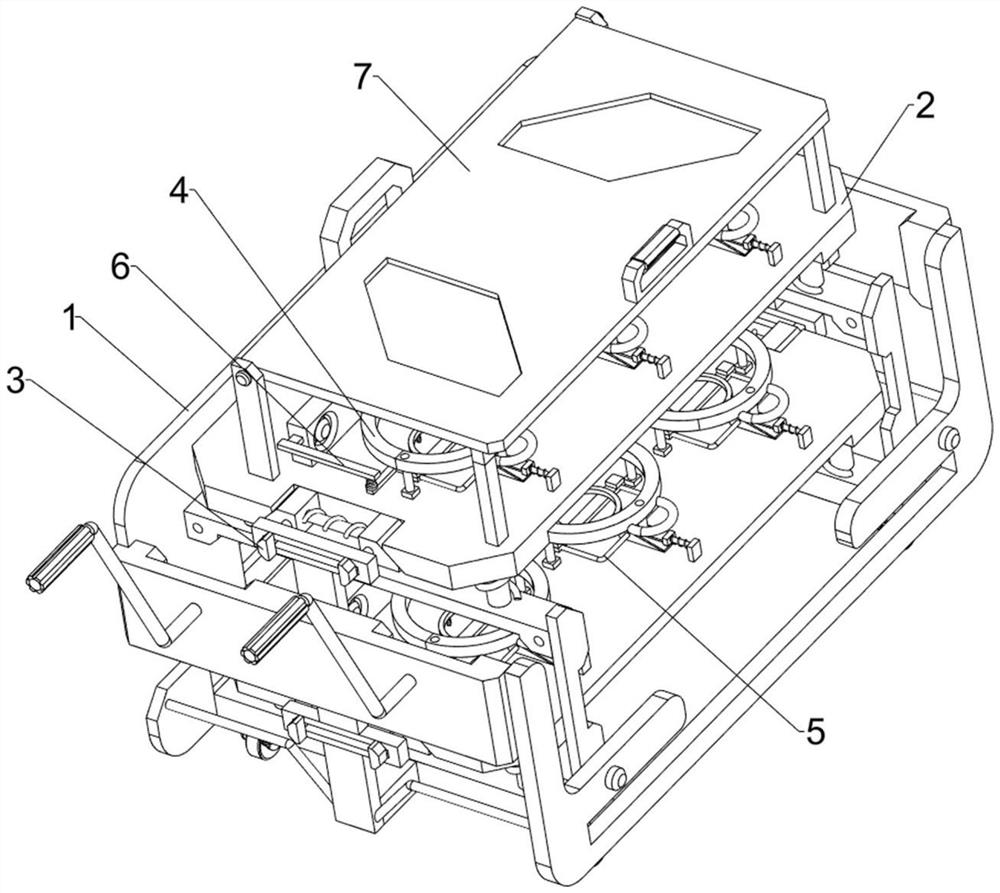

[0059] A new type of multi-layer loading equipment for ceramic parts with high stability, such as figure 1 and figure 2 As shown, it includes a trolley 1, a storage mechanism 2 and a locking mechanism 3. The trolley 1 is provided with a storage mechanism 2, and the trolley 1 is provided with a locking mechanism 3.

[0060] When people want to transport ceramic parts stably, they can use this new type of multi-layer loading equipment for ceramic parts with high stability. First, the user places multiple ceramic parts on the holding mechanism 2, which is affected by the weight of the ceramic parts. , so that the storage mechanism 2 moves downward, the storage mechanism 2 contacts the locking mechanism 3, the locking mechanism 3 tightens inward, and the storage mechanism 2 is clamped. After the user takes out the ceramic part, the locking mechanism 3 Reset, thereby driving the holding mechanism 2 to move upward.

Embodiment 2

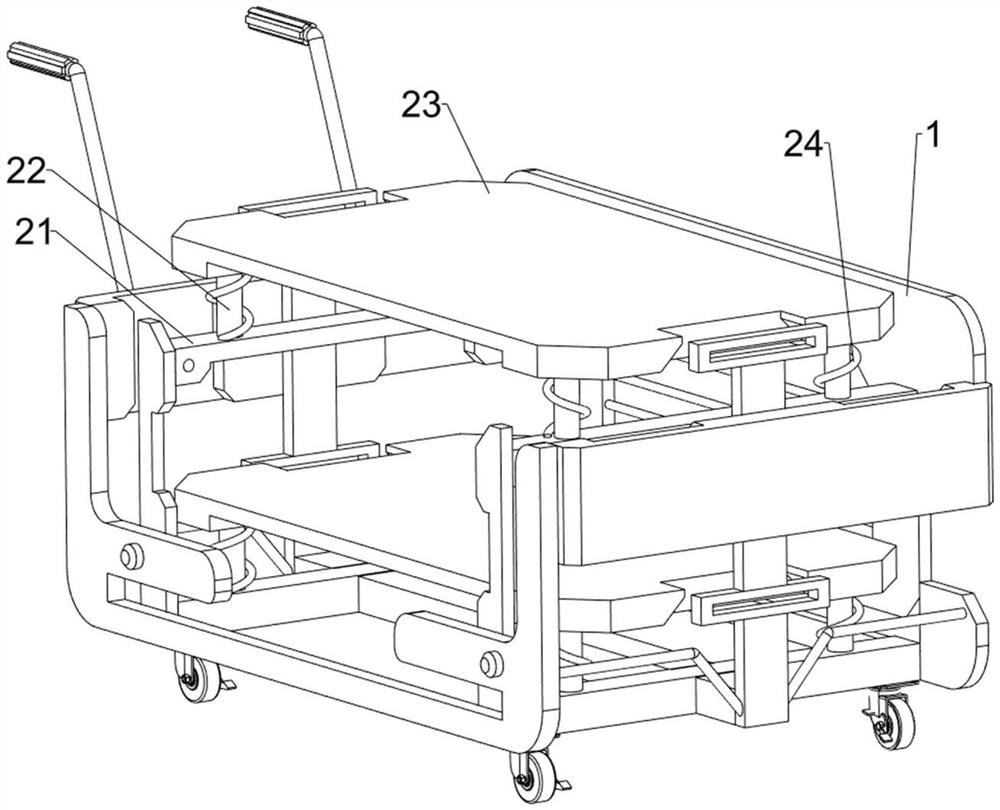

[0062] On the basis of Example 1, such as image 3 and Figure 4As shown, the holding mechanism 2 includes a first fixed frame 21, a telescopic rod 22, a placement plate 23 and a first spring 24, and the front and rear sides of the cart 1 are provided with the first fixed frame 21. Eight telescopic rods 22 are arranged between the side and the first fixed frame 21, and a placement plate 23 is connected between the tops of the four telescopic rods 22 on the same side. The first springs 24 are all wound on the eight telescopic rods 22, and the upper side The two ends of the four first springs 24 are respectively connected with the first fixed frame 21 and the placing plate 23, and the two ends of the four first springs 24 on the lower side are respectively connected with the placing plate 23 and the cart 1.

[0063] The user places a plurality of ceramic parts on the placement board 23, and is affected by the weight of the ceramic parts, so that the placement board 23 moves dow...

Embodiment 3

[0067] On the basis of Example 2, such as Figure 5-Figure 8 As shown, a clamping mechanism 4 is also included, and the clamping mechanism 4 includes a first fixing base 41, a first clamping block 42, a first fixing plate 43, a second telescopic assembly 44, a first fixing block 45 and a second clamping Block 46, the first fixing seat 41 is provided on the right side of the top of the two placing plates 23, and the left side of the two first fixing seats 41 is provided with three first clamping blocks 42, and the left side of the two placing plates 23 tops are all provided with three clamping blocks 42. A first fixed plate 43, six first fixed plates 43 are provided with second telescopic assemblies 44, six second telescopic assemblies 44 are provided with first fixed blocks 45, six first fixed blocks 45 top right Both are provided with a second clamping block 46 , and the second clamping block 46 cooperates with the first clamping block 42 .

[0068] The user pulls the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com