Transfer base for damping typemechanical equipment and usage method

A technology of mechanical equipment and shock type, applied in mechanical equipment, springs/shock absorbers, motor vehicles, etc., can solve the problems of poor shock absorption effect, damage, and affecting the normal operation of mechanical equipment, so as to improve the protection effect and improve clamping performance. The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

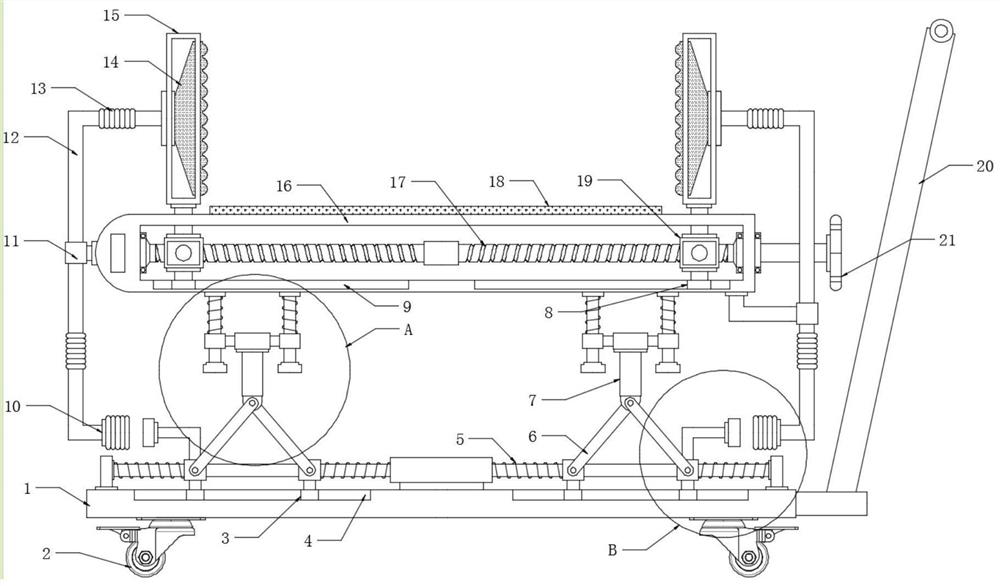

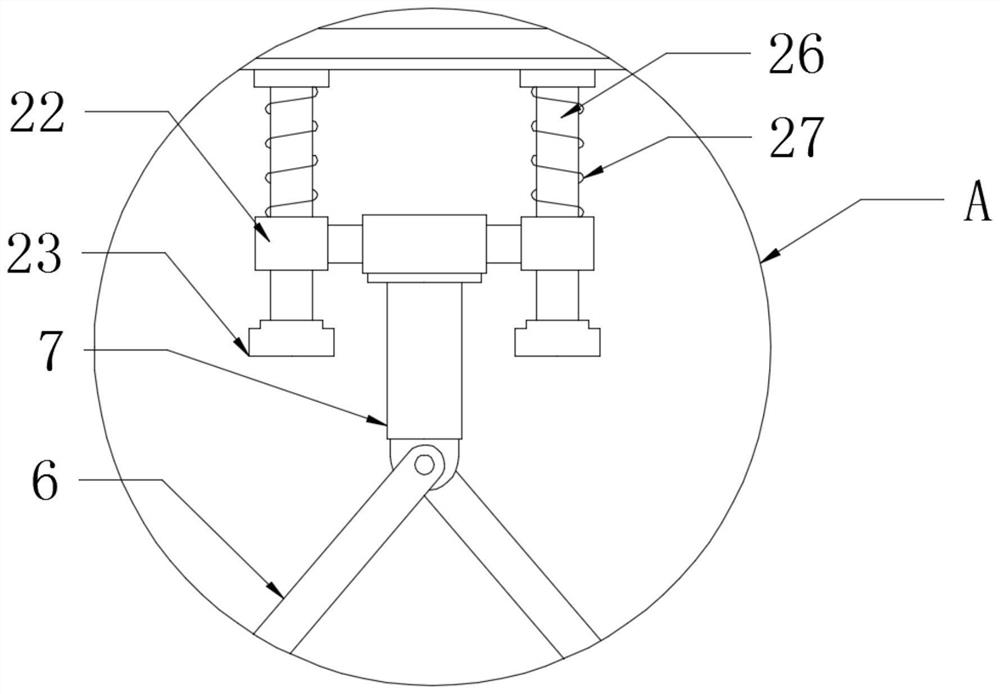

[0024] see Figure 1-3 , a transfer base for shock-absorbing mechanical equipment, including a support base 1 and a transfer platform 16, the left and right sides of the lower surface of the bottom wall of the transfer platform 16 are symmetrically provided with shock absorbing rods 26, and the surface of the shock absorbing rod 26 is fixed and installed Shock spring 27, the bottom of the shock-absorbing spring 27 is fixedly connected to the shock-absorbing slide 22, and the shock-absorbing slide 22 is slidably connected to the shock-absorbing rods 26 on the left and right sides, and the bottom of the shock-absorbing slide 22 is fixedly connected to the pillar 7, One end of the pillar 7 away from the damping slide 22 is movably connected to the push rod 6, and the left and right sides of the upper surface of the support base 1 are symmetrically provided with bearings 30, and the guide rods 28 are fixedly installed between the bearings 30 on the left and right sides. The left a...

Embodiment 2

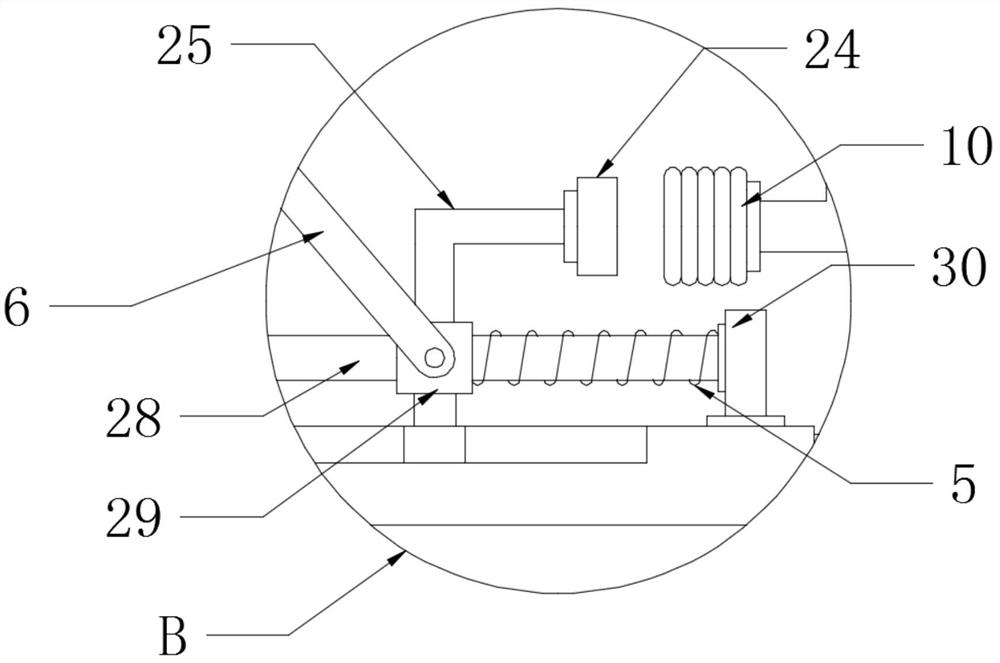

[0030] see Figure 1-3 , on the basis of Embodiment 1, in order to improve the cushioning effect between the clamps 15 on the left and right sides and the mechanical equipment, buffer airbags 14 are arranged in the clamps 15 on the left and right sides, and the convex parts of the buffer airbags 14 extend to the clamps 15 On the outside, the buffer airbag 14 is connected to the air delivery pipe 12, and the end of the air delivery pipe 12 away from the buffer airbag 14 is extended to connect the inflatable bag 10, and the upper part of the movable seat 29 is extended and fixedly connected to the push plate 24 through the L-shaped strut 25 , the push plate 24 is at the same level as the inflatable bag 10, when the movable seat 29 on both sides moves to the outside, the movable seat 29 squeezes the inflatable bag 10 through the L-shaped strut 25, and the inflatable bag 10 passes through the air tube 12 squeezes gas into the buffer air bag 14, thereby increasing the clamping forc...

Embodiment 3

[0034] A method of using a transfer base for shock-absorbing mechanical equipment is as follows:

[0035] S1. Place the mechanical equipment on the upper surface of the transfer platform 16, and by turning the handle 21, the handle 21 drives the screw 17 to rotate, and the nuts 19 on the left and right sides drive the upper clamp 15 to move inward at the same time to clamp and fix the mechanical equipment;

[0036] S2. Move and transfer by pushing the handle 20 and the universal wheel 2 .

[0037]The working principle of the present invention is: the mechanical equipment to be transferred is placed on the upper surface of the transfer platform 16, the shock absorbing slide 22 moves up and down in the vertical direction on the surface of the shock absorbing rod 26, and the shock absorbing slide 22 squeezes and absorbs shock The spring 27 stretches and contracts, and the shock absorbing spring 27 converts the external force into an elastic force to realize preliminary shock abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com