Ship rudder bearing wharf maintenance and replacement method

A technology for maintenance and replacement and rudder bearing, applied in the field of repair and replacement of ship rudder bearing wharf, can solve the problems of waste, wear of the plane bearing of the rudder bearing, narrowing of the clearance of the steering gear plunger and rudder handle, etc., and achieve the effect of saving the cost of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below in conjunction with specific embodiments:

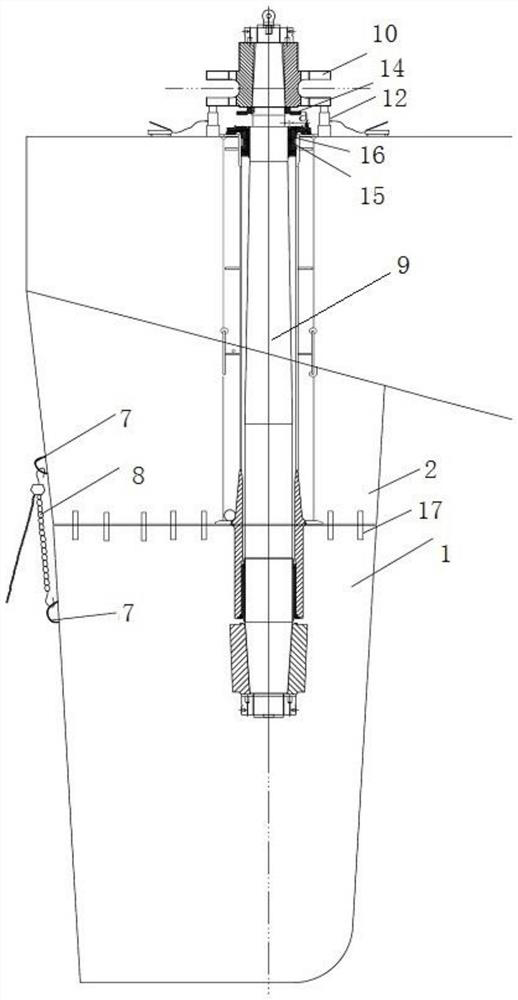

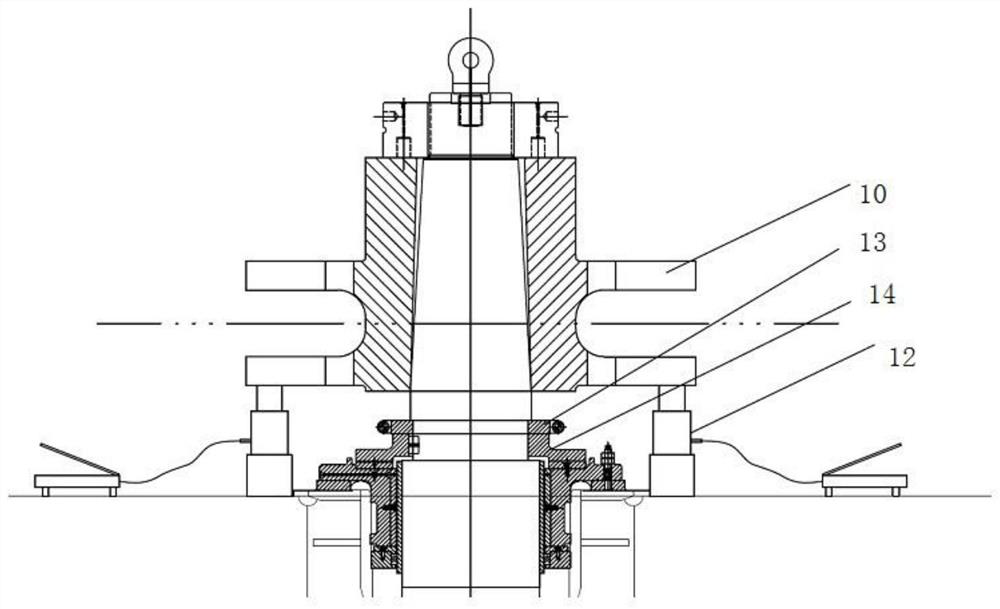

[0029] A method for repairing and replacing a ship's rudder bearing wharf, which is applicable to all rudder systems with tiller structures, such as Figure 1-6 As shown, the method includes:

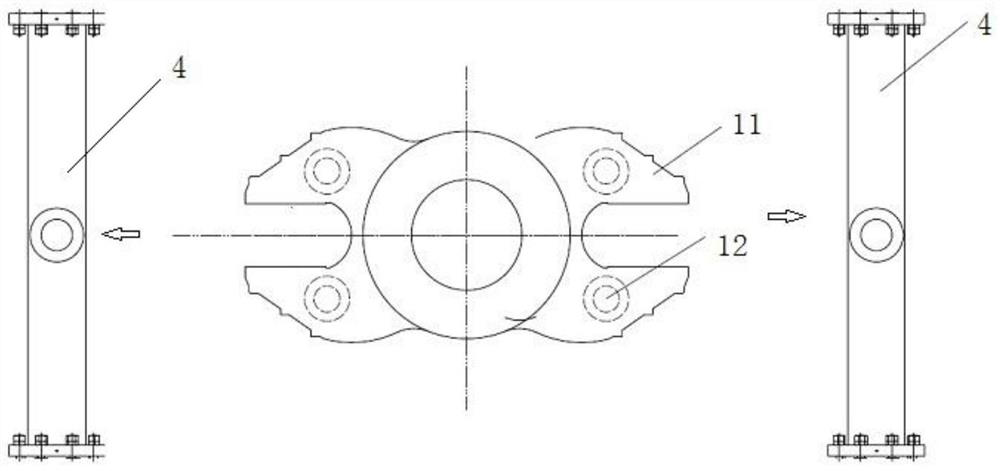

[0030] S1. Remove the anti-jump block 3 welded on the rudder blade 1 to reduce the distance between the rudder blade 1 and the upper hull structure 2 to prevent the rudder blade 1 from moving up and down in a large range, and remove the steering gear plunger 4, as figure 2 shown.

[0031] S2, according to the size of the rudder blade 1, determine the quantity of the scaffolding rings that are welded on the rudder blade for installing the scaffolding 5, the scaffolding rings 6 are 1T rings, and the distance between the scaffolding rings 6 is 2-3m, then use Wharf crane transports personnel to weld rings and set up scaffolding 5, such as Figure 5 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com